Technologic nozzle and thermal circulation heat-insulation device for same

A heat preservation device and heat cycle technology, applied in the direction of spraying device, spraying device, etc., can solve the problems of low heat exchange efficiency, larger diameter of working liquid transportation pipeline, and difficult to check leakage, etc., to achieve high heat exchange efficiency, Ingenious structural design, easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The realization of the purpose of the present invention, functional characteristics and advantages will be further described in conjunction with the embodiments and with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0024] The present invention is described in detail below in conjunction with specific embodiments.

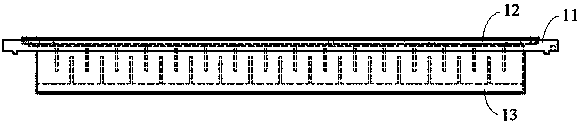

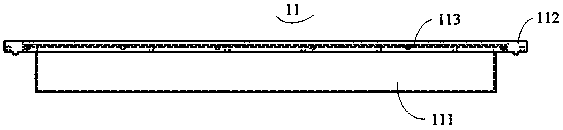

[0025] refer to Figure 1-3 , is a schematic structural diagram of Embodiment 1 of the heat cycle heat preservation device for process nozzles of the present invention, the heat cycle heat preservation device includes a cavity 11 , an upper comb-shaped baffle 12 and a lower comb-shaped baffle 13 .

[0026] The cavity 11 includes a heat exchange chamber 111, a cavity flange 112 and a first sealing ring groove 113. The wall thickness of the heat exchange chamber 111 is uniform, and its cross sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com