a tio 2 Preparation of diatomite composite material and method for purifying phosvitin phosphopeptide

A phosvitin and composite material technology is applied in the fields of composite material preparation and separation and purification of biologically active substances, and can solve the problems of complex separation process, short production cycle, numerous steps, etc., and achieve high yield and purity and regular morphology. , the effect of high activity retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

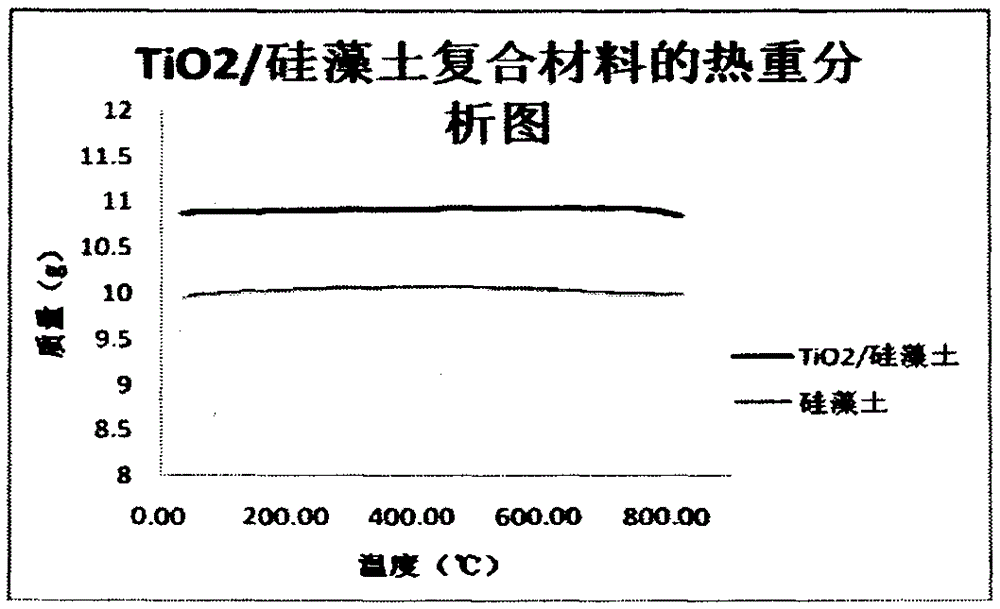

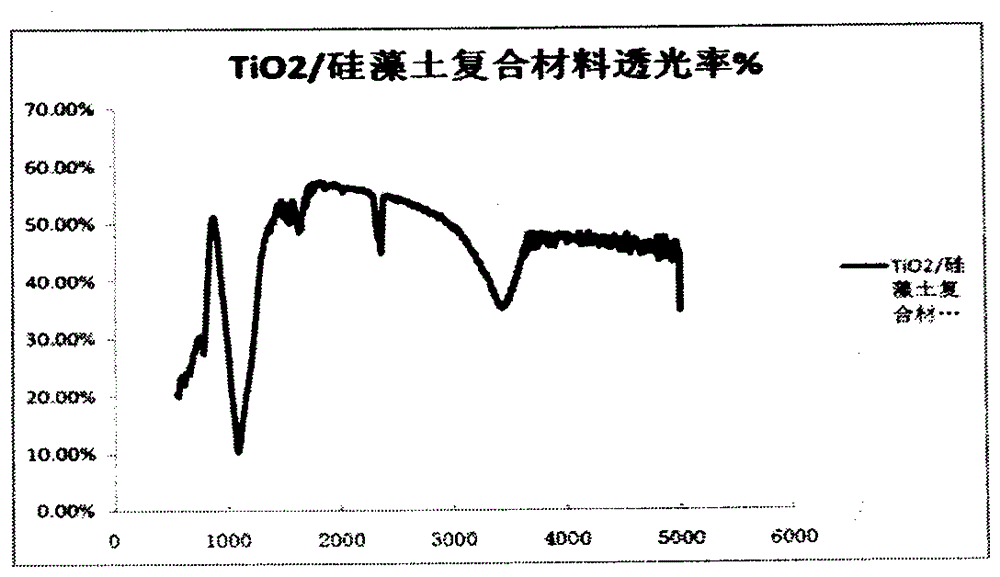

[0024] Weigh a certain amount of diatomite and disperse it in dilute hydrochloric acid with a solid-to-liquid ratio of 1:10, stir for 3 hours, then adjust the pH value to 5.0, then filter, wash, and calcinate to obtain a relatively pure carrier diatomite, wherein The concentration of dilute hydrochloric acid is 2M and the pH value is 4. Weigh a certain mass of purified diatomite, add hydrochloric acid with a solid-to-liquid ratio of 1:10 and a concentration of 2M, stir for 30 minutes, and then add a certain volume of TiCl 4 solution, continue to stir for 2h, then adjust the pH value of the reaction system to 4, and then react for 2h under stirring conditions to terminate the reaction. Filter and wash the material with deionized water until the filtrate is free of Cl ions, using a stirring rate of 500 rpm. The above materials were dried and calcined at 800°C for 5h to obtain TiO 2 / Diatomaceous earth composite material.

Embodiment 2

[0028] Weigh a certain amount of diatomite and disperse it in dilute hydrochloric acid with a solid-to-liquid ratio of 1:10, stir and react for 3 hours, then adjust the pH value to 4.0, then filter, wash, and calcinate to obtain relatively pure carrier diatomite, wherein The concentration of dilute hydrochloric acid is 2M and the pH value is 4. Weigh a certain quality of purified diatomite, add hydrochloric acid with a solid-liquid ratio of 1:10 and a concentration of 0.1M, stir for 30 minutes, and then add a certain volume of TiCl 4Solution, continue to stir for 2h, then adjust the pH value of the reaction system to 6, react under stirring conditions for 2h, terminate the reaction, filter, wash the material with deionized water until the filtrate does not contain Cl ions, and the stirring rate used is 400rpm. The above materials were dried and calcined at 500°C for 5h to obtain TiO 2 / Diatomaceous earth composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com