Ground wire protection device and ground wire laying method

A technology of protection device and laying method, applied in the direction of connection, connection contact material, circuit/collector parts, etc., can solve the hidden danger of power system safe operation, increase labor intensity, electrical equipment tripping and other problems, and achieve convenient detection and The effect of replacement operation, reducing the number of inspections, and improving grounding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

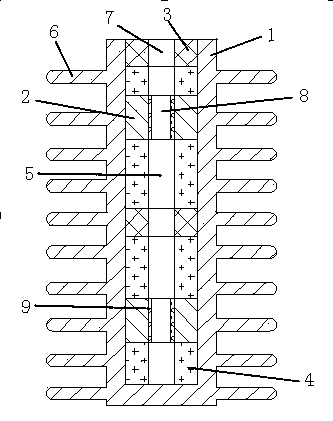

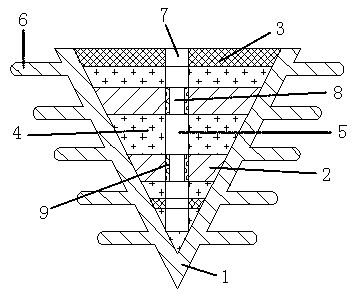

[0012] Such as figure 1 and 2 As shown, a ground wire protection device, the ground wire protection device is composed of a sheath 1, a conductive ring 2, a sealing ring 3 and a moisture-proof filler 4, the center of the sheath 1 is provided with a release pipe 5, and its outer wall Uniformly distributed annular projections 6 perpendicular to the axial direction of the release tube 5, the diameter of the annular projections 6 is at least one time the diameter of the release tube 5, and integrally formed with the sheath 1, the sealing ring 3 is at least two There is a wire hole 7 in the middle, and it is evenly distributed inside the sheath 1 from the top of the sheath 1, and a moisture-proof filler 4 is set between the two sealing rings 3 and between the sealing ring 3 and the inner wall of the sheath 1. The conductive There are at least two rings 2, which are evenly distributed inside the discharge pipe 5. The conductive ring 2 is provided with a wiring hole 8, and a conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com