Preparation method of polyethylene n-butyl ether based gel polymer electrolyte capacitor

A capacitor and gel-based technology, applied in the field of capacitors, can solve problems such as poor contact, complex film-making process, and large internal resistance, and achieve the effects of reducing internal resistance, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] An embodiment of the present invention provides a method for preparing a polyethylene n-butyl ether-based gel polymer electrolyte capacitor, which includes the following steps:

[0012] S01: Stack and wind in sequence according to the order of electrodes / diaphragms / electrodes, and put them into the capacitor case;

[0013] S02: Mix 0.5-2mol / L quaternary ammonium salt ionic liquid electrolyte, vinyl n-butyl ether and initiator in a mass ratio of (5-10):1:(0.002-0.02) to obtain a mixed solution;

[0014] S03: Inject the mixed solution into the capacitor casing, seal it, and keep it at 60° C. to 80° C. for 12 to 48 hours to obtain a polyvinyl n-butyl ether-based gel polymer electrolyte capacitor.

[0015] Specifically, in step S01, the electrode is preferably a graphene electrode, and the preparation of the graphene electrode can adopt the following method:

[0016] Mix graphene, conductive agent and binder according to the mass ratio of (85-90):(3-7):(5-10), add solvent,...

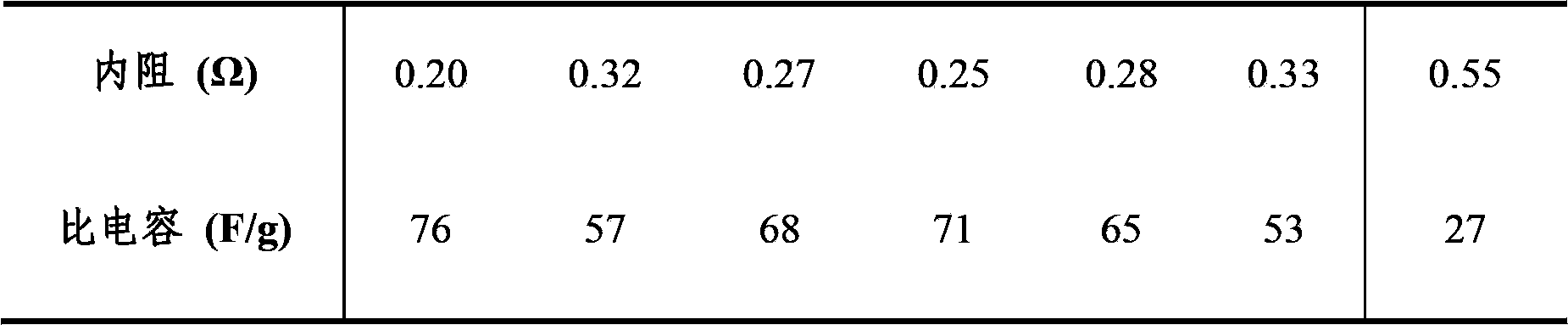

Embodiment 1

[0024] Prepare graphene electrode: weigh graphene (specific surface area is about 1000m 2 / g) 4.5g, 0.26g of acetylene black, 0.53g of PVDF, and NMP (30mL) was added, and fully stirred to make it a uniformly mixed slurry. Then it was scraped-coated on an aluminum foil cleaned by ethanol, dried to constant weight at 100°C under a vacuum of 0.01 MPa, and rolled to form a graphene electrode under a pressure of 10 MPa. The thickness of the prepared graphene electrode is about 140 μm.

[0025] Preparation of polyethylene n-butyl ether-based gel polymer electrolyte capacitor: In a glove box filled with argon gas, the prepared graphene electrodes were stacked and wound in the order of electrode / celgard separator / electrode, and packed into the capacitor case. The pre-prepared 1mol / L Et 4 NBF 4 / AN, vinyl n-butyl ether and initiator BPO (dibenzoyl peroxide) are mixed evenly in a mass ratio of 9:1:0.01. Then, the mixed solution was injected into the capacitor and sealed. Finally, t...

Embodiment 2

[0027] Prepare graphene electrode: weigh graphene (specific surface area is about 200m 2 / g) 4.5g, conductive carbon black 0.3g, PVDF 0.7g, and NMP (50mL) was added, fully stirred to become a uniformly mixed slurry. Then it was scraped-coated on an aluminum foil cleaned with ethanol, dried at 100°C under a vacuum of 0.01 MPa to constant weight, and rolled under a pressure of 15 MPa to form a graphene electrode. The thickness of the prepared graphene electrode is about 100 μm.

[0028] Preparation of polyethylene n-butyl ether-based gel polymer electrolyte capacitor: In a glove box filled with argon gas, the prepared graphene electrodes were stacked and wound in the order of electrode / celgard separator / electrode, and packed into the capacitor case. The pre-prepared 0.5mol / L Et 4 NBF 4 / AN, vinyl n-butyl ether and initiator BPO (dibenzoyl peroxide) are mixed evenly in a mass ratio of 5:1:0.002. Then, the mixed solution was injected into the capacitor and sealed. Finally, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com