High-temperature high-pressure combustion structure of pure oxygen combined heat carrier generator

A composite heat carrier, high temperature and high pressure technology, applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of affecting service life, ablation, inability to ensure mixing and high temperature resistance requirements, etc., to avoid The effects of gas channeling, high utilization rate of heat energy and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

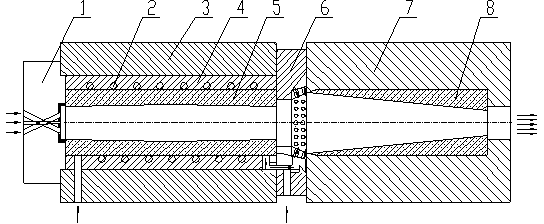

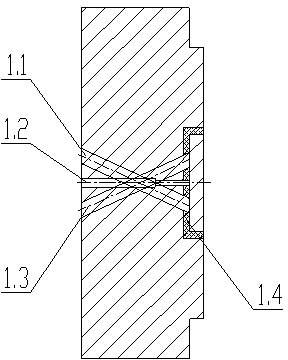

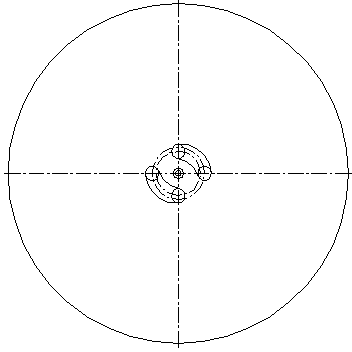

[0042] See figure 1 , The present invention is a pure oxygen composite heat carrier generator high temperature and high pressure combustion structure, which includes generator fuel and pure oxygen combined supply and ignition structure 1, strength maintaining body shell 3, main combustion chamber 4, combustion chamber 5, mixing The mixing connection body 6, the main gasification shell 7 and the gasification zone heat-resistant layer 8, the generator fuel and pure oxygen combined supply and ignition structure 1 is embedded in the front end of the strength maintaining body shell 3. The main gasification shell The body 7 is arranged behind the strength-maintaining body shell 3, and the strength-maintaining body shell 3 and the main gasification shell 7 are fastened and connected by a blending connecting body 6 to form a functionally independent but unobstructed combustion chamber and a gasification chamber, so The inner wall of the strength holding body shell 3 is provided with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com