Stainless steel passivation process

A technology of stainless steel and technology, applied in the field of stainless steel passivation technology, can solve problems such as insecurity, achieve strong corrosion resistance, complete passivation film, and improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

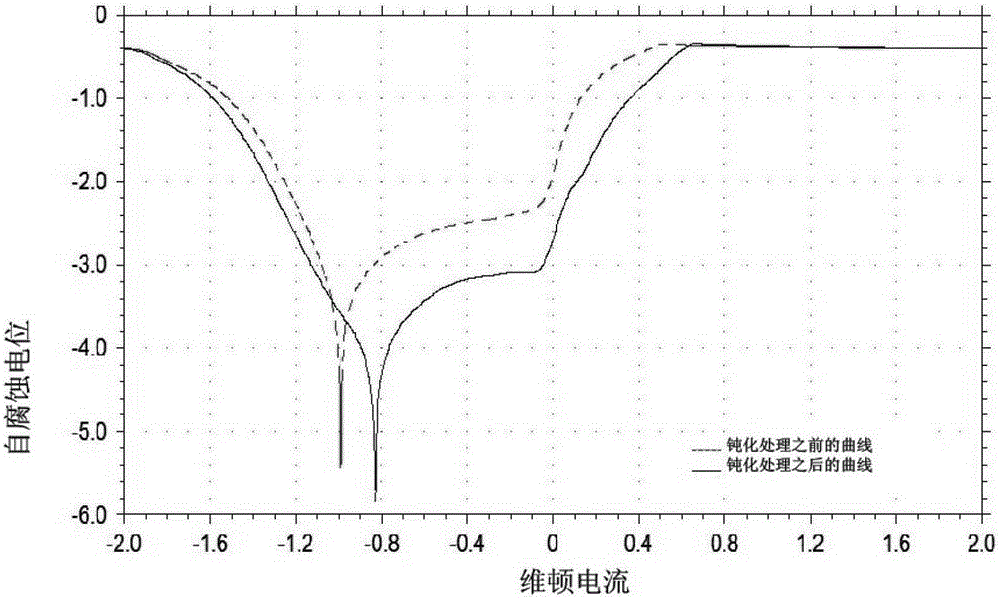

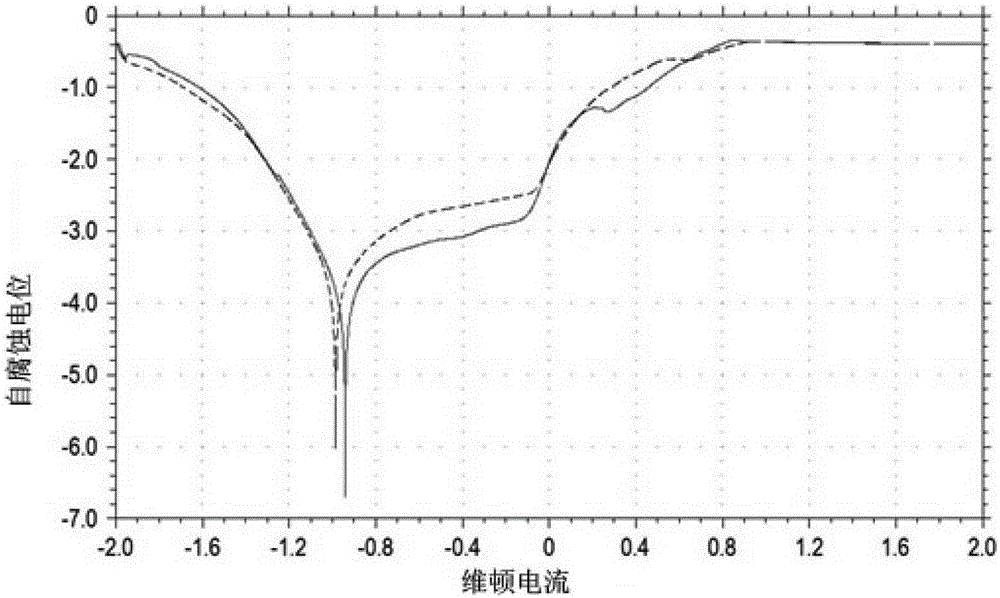

Image

Examples

Embodiment 1

[0023] A stainless steel passivation process is used to passivate 304 stainless steel, the steps are as follows:

[0024] Step 1. Mechanical polishing, polishing with 400, 600, and 800-grit sandpaper in turn.

[0025] Step 2. Degreasing, at room temperature, put the mechanically polished 304 stainless steel into 5g of Na 2 CO 3 , 3.75g of NaOH, 5g of Na 3 PO 4 , 2.5ml of OP-10, and 250ml of H 2 Soak in O for 10 minutes to remove oil stains on the surface of 304 stainless steel;

[0026] Step 3. Pickling, put the degreased 304 stainless steel into 75ml of H at normal temperature 3 PO 4 , 50ml of H 2 SO 4 , 100ml of H 2 Soak in the solution prepared by O for 6 minutes to remove the scale and rust on the surface of the stainless steel;

[0027] Step 4. electrolytic polishing, the H containing 600ml / L 3 PO 4 , 275ml / L H 2 SO 4 , 125ml / L H 2 The solution that the polyethylene glycol of 0, 8g / L, the glucose of 10g / L is formulated as electrolytic solution, adopts the v...

Embodiment 2

[0035] Adopt a stainless steel passivation process to passivate 316 stainless steel, the steps are as follows:

[0036] Step 1. Mechanical polishing, polishing with 400, 600, and 800-grit sandpaper in turn.

[0037] Step 2. Degreasing, at room temperature, put the mechanically polished 304 stainless steel into 5g of Na 2 CO 3 , 3.75g of NaOH, 5g of Na 3 PO 4 , 2.5ml of OP-10, and 250ml of H 2 Soak in O for 10 minutes to remove oil stains on the surface of 304 stainless steel;

[0038] Step 3. Pickling, put the degreased 316 stainless steel into H at room temperature 3 PO 4 75ml, H 2 SO 4 50ml, H 2 Soak 6min in the solution that 0100ml is prepared to remove scale and rust on the stainless steel surface;

[0039] Step 4. Electrolytic polishing, put H 3 PO 4 600ml / L, H 2 SO 4 275ml / L, H 2 0125ml / L, Polyethylene Glycol 8g / L, the solution that glucose 10g / L is formulated as electrolyte, adopt the voltage of 7V, at the temperature of 50 degrees centigrade, the describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com