Preparation method of arachidonic acid

A technology of arachidonic acid and strains, applied in the field of arachidonic acid preparation, can solve the problems of low biomass, low oil content, late start of research, etc., and achieve simple fermentation process, easy purchase of raw materials, and convenient preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1. utilize Mortierella alpina to produce ARA

[0039] Mortierella alpina was cultured in a 250mL shake flask with a carrier volume of 50mL activation medium at 150rpm at 28°C for 3 days. Then insert the activated strain into the basal medium, put 50mL of the basal medium into a shaker flask with a liquid volume of 250mL, and inoculate 10% (v / v), and cultivate it in a reciprocating shaker at 28°C for 5-6 days, with a rotation speed of 150rpm , 28°C, harvested after 5 days of cultivation, harvested biomass by suction filtration, dried it at constant temperature to constant weight, ground and extracted oil with n-hexane, and evaporated to remove the organic solvent to obtain a total oil of 5g / L.

[0040] Activation medium composition (g / L):

[0041]

[0042]

[0043] Basal medium composition (g / L):

[0044]

[0045] The rest is water, pH 6.0.

Embodiment 2

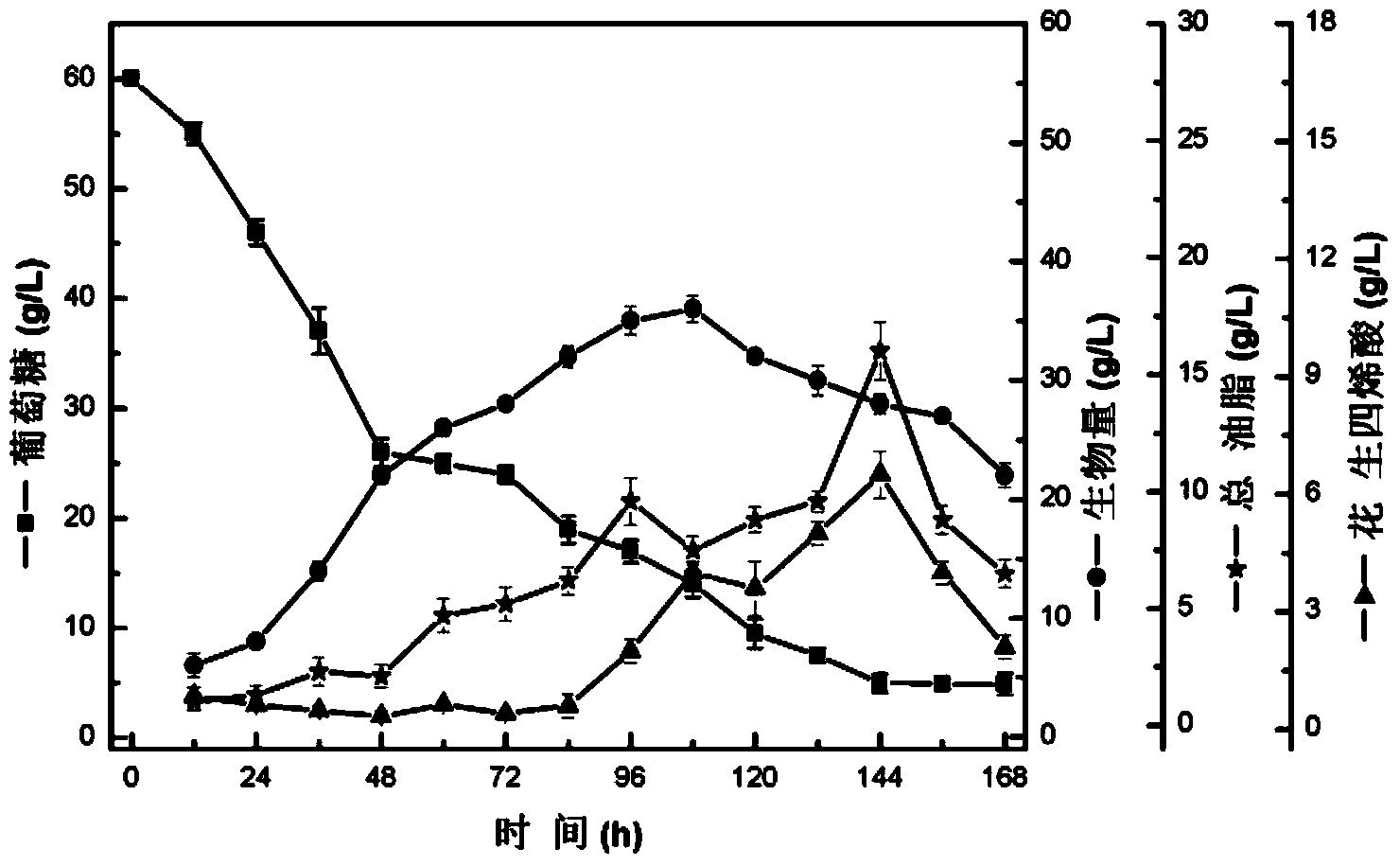

[0046] Embodiment 2. Utilize basal medium to cultivate Mortierella alpina to produce ARA in fermenter

[0047] Culture in a 2L fermenter with a liquid volume of 1.5L of basic medium (as in Example 1), set the initial glucose concentration at 60-65g / L, sterilize separately, maintain the fermentation temperature at 28°C, and initially stir at 150-200rpm. Mortierella alpina was fermented in batches under the condition of ventilation volume 1vvm, the pH was adjusted to 6.5-7.0 before sterilization, and the initial pH after sterilization was 6.0-6.5. After 12 hours of cultivation, the dissolved oxygen began to drop rapidly, and the growth entered In the logarithmic phase, after 48 hours of cultivation, the growth begins to enter the stable phase. During the entire growth cycle, the initial pH value is 6.0-6.5. During the process, the pH value first increases, then decreases and then increases again. Stable between 7.0 and 7.9; dissolved oxygen decreased rapidly with the increase of...

Embodiment 3

[0049] Embodiment 3. Amino acids, vitamins and trace elements are on the impact of Mortierella alpina biomass and ARA oil content

[0050] Growth factors (vitamins, amino acids) and trace elements were added to the basal medium in Example 2 to increase the yield.

[0051] Added growth factors include:

[0052]

[0053] The vitamins are made into a 500× concentrate, sterilized by filtration with a 0.2 μm sterile filter membrane, and stored in a refrigerator at 4°C, and added directly to the basic medium before inoculation, with an addition amount of 2mL / L. Glutamic acid is added when preparing the basal medium before sterilization, and is sterilized together with the medium.

[0054] The added trace elements include (g / L):

[0055]

[0056] Trace elements were made into 1000×concentrate (that is, 1mL trace element concentrate was added to 1L medium), and adjusted to pH7. Use a 0.2 μm sterile filter membrane to filter and sterilize, store in a refrigerator at 4°C, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com