Rod-like niobium pentoxide template grain and preparation method thereof

A technology of niobium pentoxide and crystal grains, which is applied in the field of rod-shaped niobium pentoxide template grains and its preparation, which can solve the problems of unsuitable nanorods and achieve the effect of improving piezoelectric performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] As an example, specifically, the preparation method of the present invention may include the following steps.

[0033] (1) Weigh Nb according to the ratio of raw material and molten salt 1:1~10 (mass ratio) 2 O 5 And soluble sodium salt powder, pour ethanol into it, and use ZrO 2 Balls, steel balls, or agate balls are used as media and mixed in a ball mill for 1 to 3 hours. Wherein, the soluble sodium salt may be at least one of sodium chloride, sodium nitrate, sodium sulfate and sodium carbonate. The ball mill may be, for example, a planetary ball mill. Preferably, before weighing the raw material powder, it can be baked at 100°C to 150°C for more than 3 hours to obtain a dry raw material powder.

[0034] (2) Heat and dry the raw materials after ball milling, and put them into a closed crucible for synthesis: put the crucible with powder into a heating device such as a muffle furnace, and quickly heat up to 1000 at a rate of 5-10°C / min ~1100℃, after incubation for 40~80, ...

Embodiment 1

[0039] ① Ingredients ball mill: Weigh AR grade Nb 2 O s (99.96%) 40.1263g, AR grade NaCl (99.80%) 40.1266g, add a certain amount (depending on the fluidity of the slurry) of absolute ethanol, and use ZrO in a planetary ball mill 2 The balls are mixed with the medium for 2 hours, and the mixed slurry is dried in an oven at 80℃;

[0040] ②Molten salt reaction: The dried powder is put into an alumina crucible with a cover, and put into a muffle furnace for synthesis. The synthesis conditions are 1050℃, the temperature is kept for 60min, the heating rate is 5℃ / min, and the cooling rate is 5℃ / min after the completion of the heat preservation;

[0041] ③Washing and drying: Put the reacted powder into a suitable size beaker, and wash it repeatedly with hot deionized water until no C1 is detected in the filtrate - until. Filter and dry the washed powder to obtain rod-shaped Nb 2 O 5 Powder.

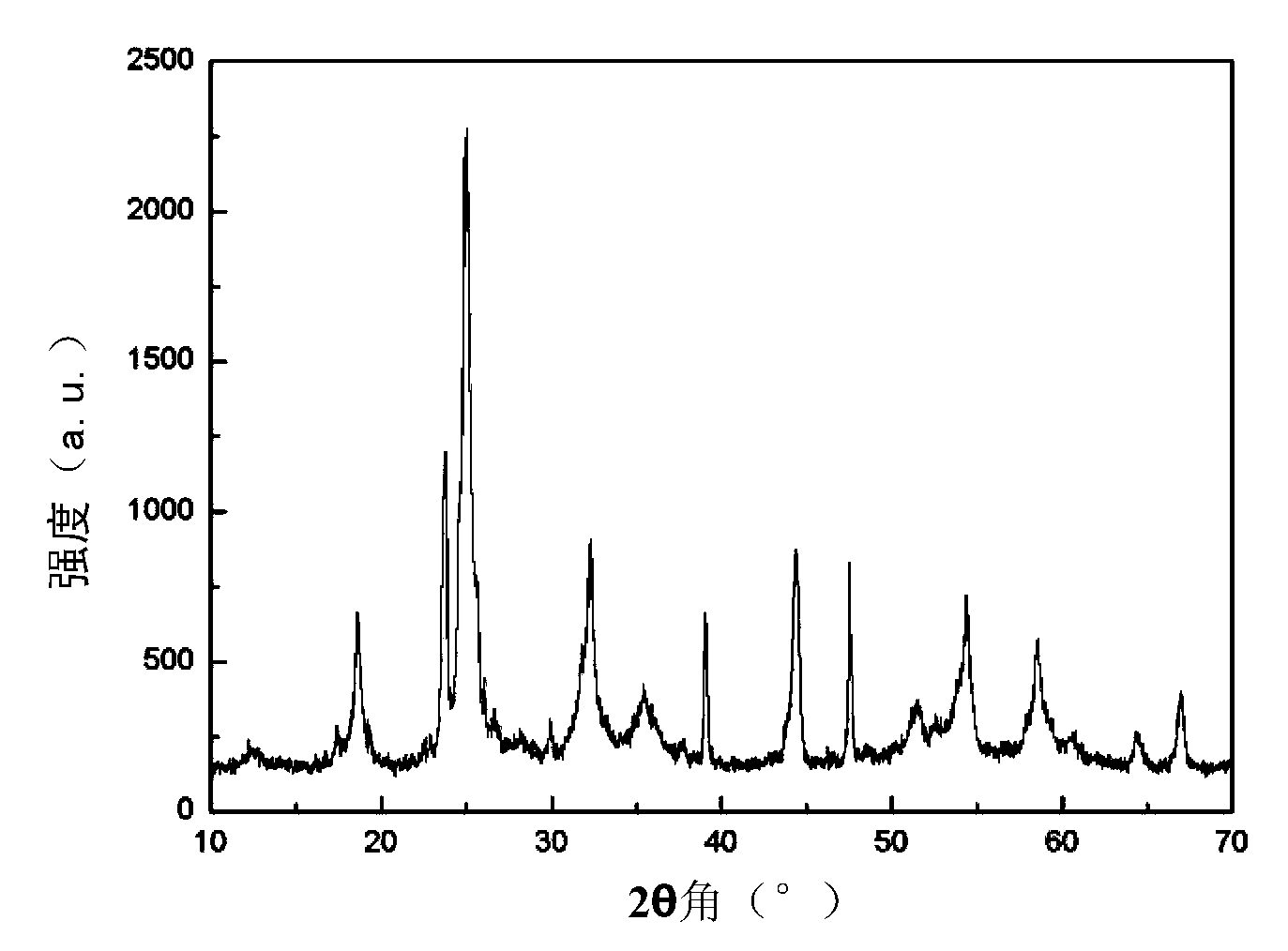

[0042] The XRD diffraction pattern of the niobium pentoxide powder prepared in this example is show...

Embodiment 2

[0044] ① Ingredients ball mill: Weigh AR grade Nb 2 O 5 (99.96%) 40.0015g, AR grade NaCl (99.80%) 40.0013g, add a certain amount (depending on the fluidity of the slurry) of absolute ethanol, use ZrO in a planetary ball mill 2 The balls are mixed with the medium for 2 hours, and the mixed slurry is dried in an oven at 80℃;

[0045] ②Molten salt reaction: The dried powder is put into an alumina crucible with a cover, and put into a muffle furnace for synthesis. The synthesis condition is 1050℃, the temperature is kept for 60 minutes, the heating rate is 10C / min, and the temperature drop rate is 5C / min after the completion of the heat preservation;

[0046] ③Washing and drying: Put the reacted powder into a suitable size beaker, and wash it repeatedly with hot deionized water until no C1 is detected in the filtrate - until. Filter and dry the washed powder to obtain rod-shaped Nb 2 O 5 powder.

[0047] The XRD diffraction pattern of the niobium pentoxide powder prepared in this exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com