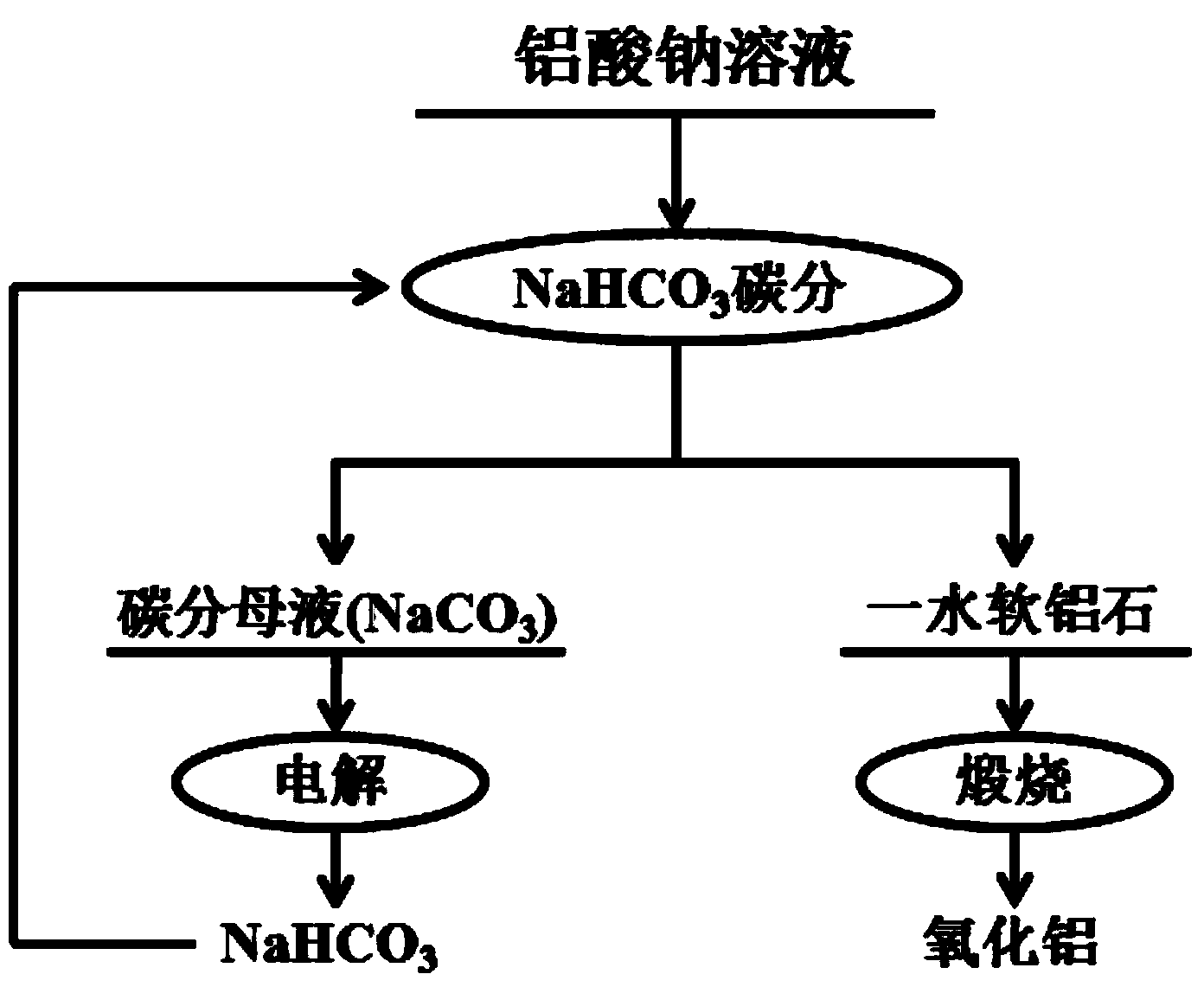

Method for preparing boehmite by liquid phase carbonating decomposition of sodium aluminate solution and sodium bicarbonate

A technology of sodium bicarbonate solution and sodium bicarbonate, which is applied in the field of alumina production, can solve the problems of pending research, high quality requirements of bauxite, high energy consumption, etc., and achieve the effect of high decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Prepare 200ml of sodium aluminate solution with industrial aluminum hydroxide and sodium hydroxide, the chemical composition is Al 2 o 360 g / L, causticization coefficient is 1.3, decomposition solution temperature is 85°C, stirring speed is 100r·min -1 Under these conditions, add boehmite seed crystals with a seed coefficient of 0.1, and use a peristaltic pump to add a concentration of 60 g / L NaHCO 3 Solution, adding rate 0.2g·L -1 min -1 , the decomposition time is 2h, and the precipitated boehmite is separated from the carbon mother liquor to obtain the product boehmite. The obtained carbon fraction mother liquor is electrolyzed by a diaphragm, the temperature of the electrolytic solution is 40°C, the electrolysis time is 4h, and the current density is 0.01A / cm 2 , getting NaHCO in the anode region 3 solution, adjusted to an appropriate concentration for use.

[0028] The decomposition products of sodium aluminate solution and the results of electrolysis of carb...

Embodiment 2

[0032] Prepare 200ml of sodium aluminate solution with industrial aluminum hydroxide and sodium hydroxide, the chemical composition is Al 2 o 3 120 g / L, causticization coefficient 1.7, decomposition solution temperature 95°C, stirring speed 200r·min -1 Under these conditions, add boehmite seed crystals with a seed coefficient of 1.0, and use a peristaltic pump to add NaHCO with a concentration of 80 g / L 3 Solution, adding rate 0.8g·L -1 min -1 , the decomposition time is 4h, and the precipitated boehmite is separated from the carbon mother liquor to obtain the product boehmite. The obtained carbon fraction mother liquor is electrolyzed by a diaphragm, the temperature of the electrolytic solution is 50°C, the electrolysis time is 8h, and the current density is 0.1A / cm 2 , getting NaHCO in the anode region 3 solution, adjusted to an appropriate concentration for use.

[0033] The results are shown in Table 2

[0034] Table 2 Sodium aluminate solution decomposition product...

Embodiment 3

[0037] Prepare 200ml of sodium aluminate solution with industrial aluminum hydroxide and sodium hydroxide, the chemical composition is Al 2 o 3 140 g / L, causticization coefficient 1.5, decomposition solution temperature 85°C, stirring speed 300r·min -1 Under these conditions, add boehmite seed crystals with a seed coefficient of 2.0, and use a peristaltic pump to add NaHCO with a concentration of 100 g / L 3 Solution, adding rate 0.4g·L -1 min -1 , the decomposition time is 7h, and the precipitated boehmite is separated from the carbon mother liquor to obtain the product boehmite. The obtained carbon fraction mother liquor is electrolyzed by a diaphragm, the temperature of the electrolytic solution is 60°C, the electrolysis time is 16 hours, and the current density is 0.02A / cm 2 , getting NaHCO in the anode region 3 solution, adjusted to an appropriate concentration for use.

[0038] The results are shown in Table 3

[0039] Table 3 Sodium aluminate solution decomposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com