Direct turning and roughing method for optical collecting lens of extreme ultra-violet lithography light source

An extreme ultraviolet lithography and collecting mirror technology, which is applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of high processing technology requirements and increase processing costs, saving time and processing costs, and shortening processing cycles. Dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

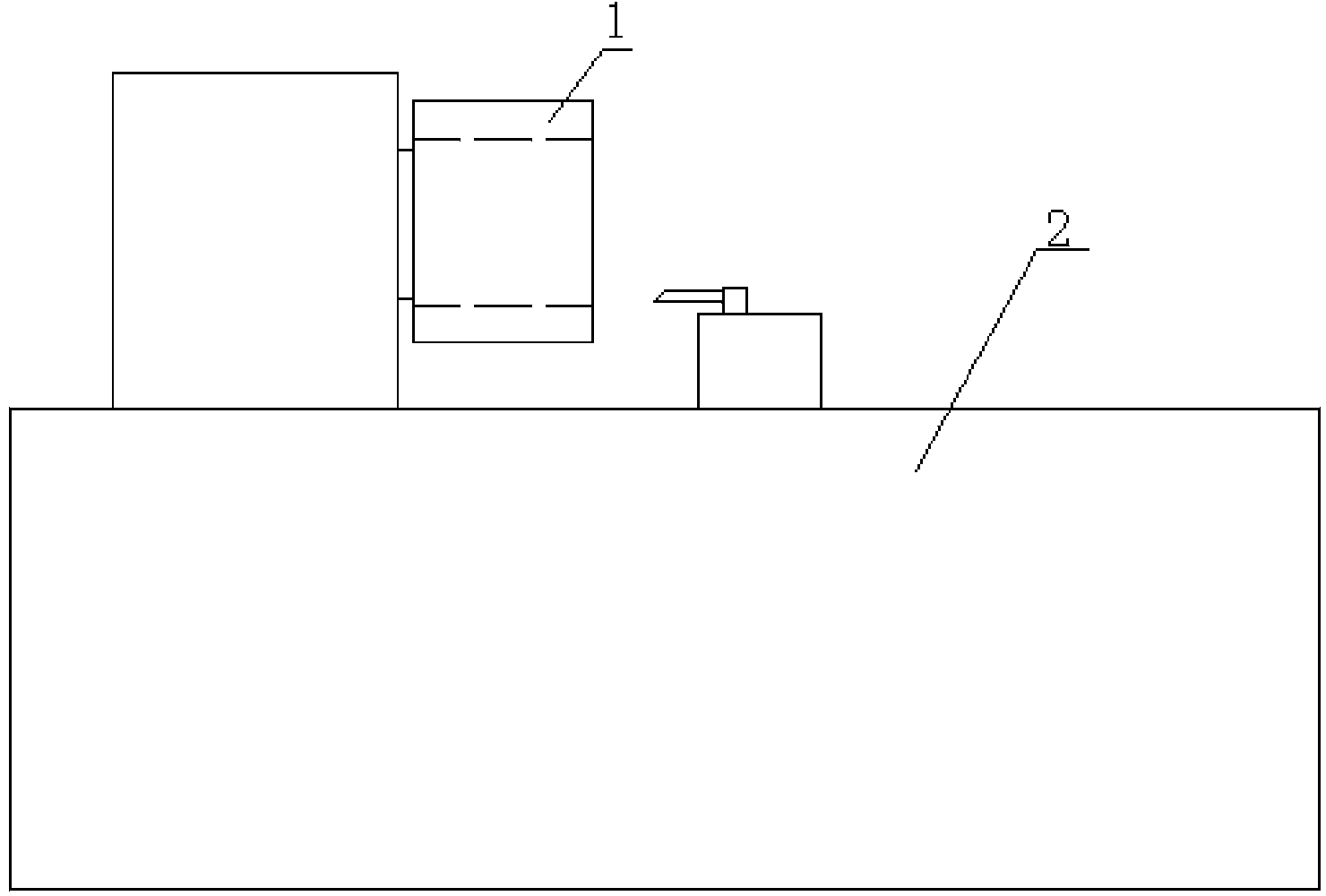

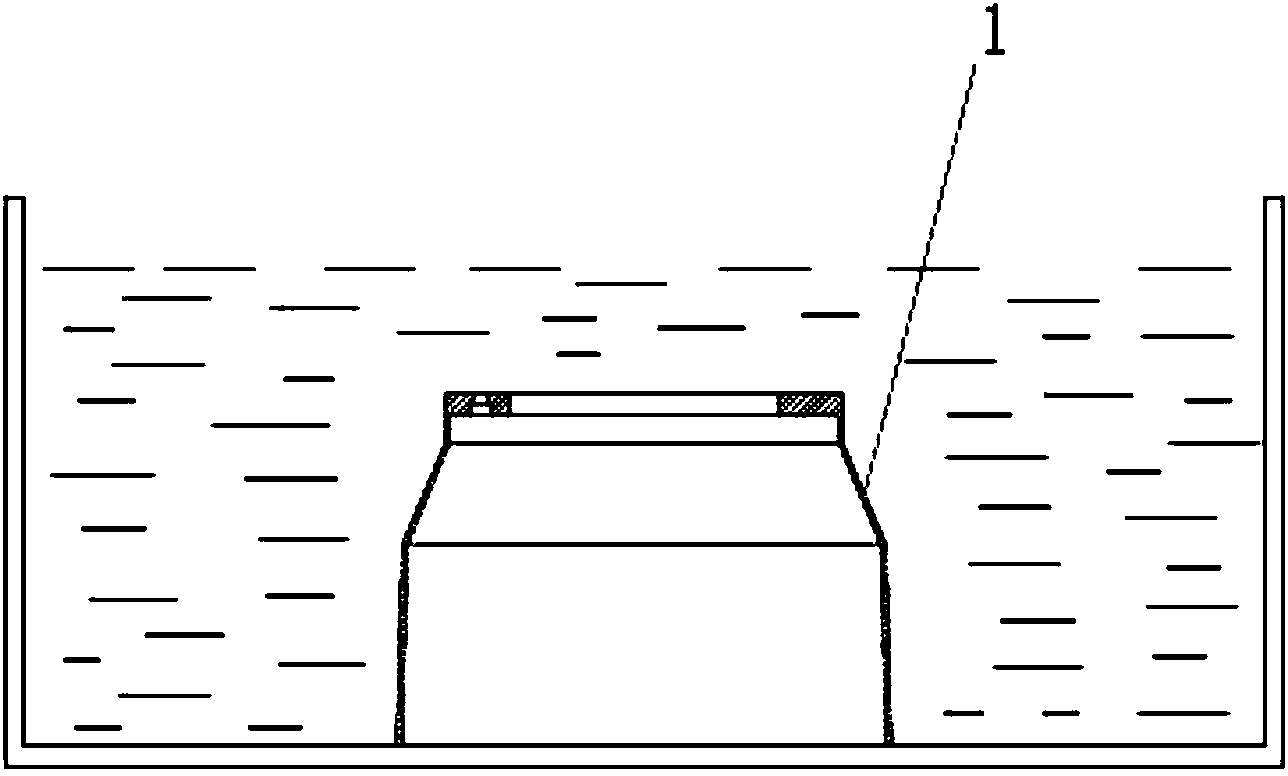

[0014] Specific implementation mode one: combine Figure 1-Figure 4 To illustrate this embodiment, the direct turning rough machining method of the optical collecting mirror in the extreme ultraviolet lithography light source of this embodiment is realized according to the following steps:

[0015] 1. Rough turning of the billet. First, the aluminum alloy billet is rough-turned into a cylindrical workpiece 1 by using an ordinary lathe 2. The wall thickness of the processed cylindrical workpiece 1 is 22mm-24mm; the blank is a cylinder or a bar;

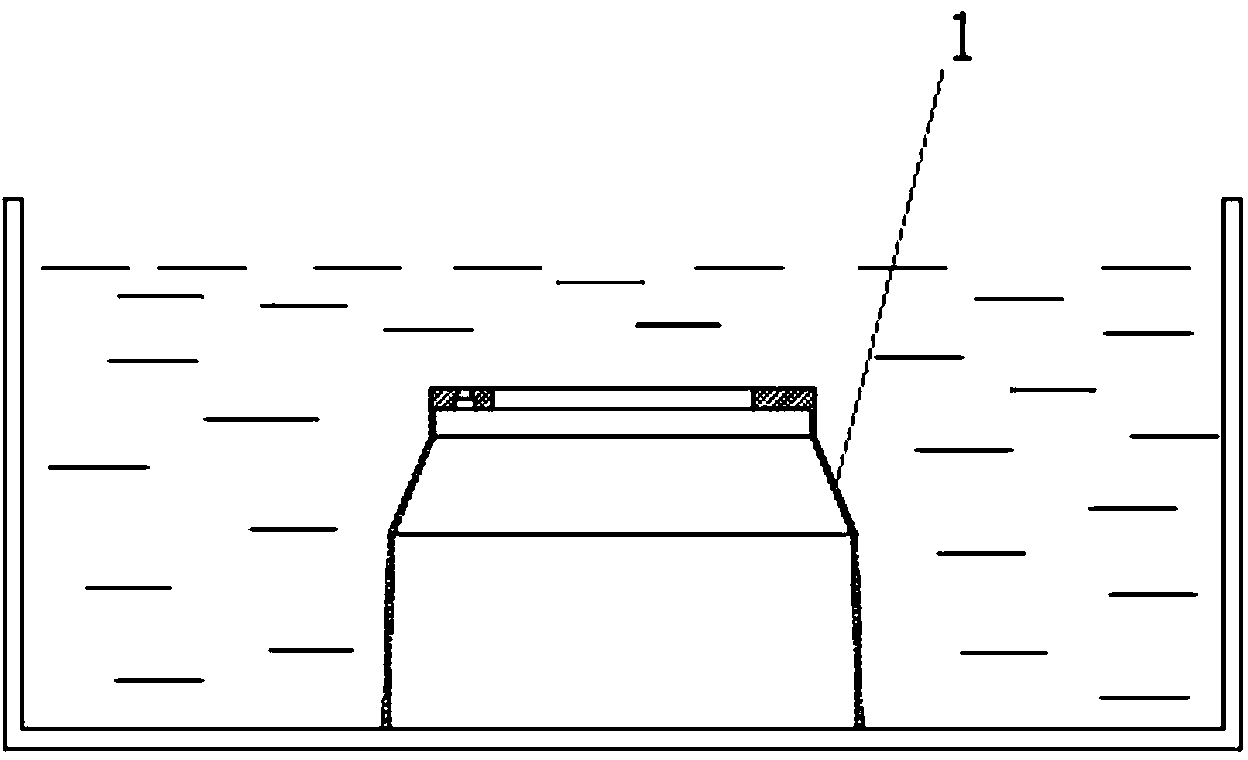

[0016] 2. CNC turning, the cylindrical workpiece 1 is turned by the CNC lathe according to the collection mirror surface, first turning the inner surface of the cylindrical workpiece 1, turning 6-8 times, each feeding 1mm-2mm, the cylindrical workpiece after each turning Carry out a dimensional stabilization treatment, the process step of each dimensional stabilization treatment is to first carry out cold treatment to the cylindrical w...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 The present embodiment will be described. The thickness of the cylindrical workpiece 1 processed in the present embodiment is 23 mm. In this embodiment, the turning thickness of the inner surface of the cylindrical workpiece is 10 mm, and the turning thickness of the outer surface is 10 mm. The wall thickness of the finally obtained collecting mirror tube blank is 2.3 mm, which ensures the reserved amount for finishing. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that when turning the inner surface of the tubular workpiece 1 in step 2, the amount of turning decreases gradually with the increase in the number of dimensional stabilization treatment cycles. Since a dimensional stabilization treatment is required for each turning, the dimensional stability of the billet material is well guaranteed, and the surface shape and roughness requirements are guaranteed, which saves processing costs and processing time. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com