Preparation method of nanometer WC-Co composite powder

A kind of composite powder and nanotechnology, which is applied in the field of nanocomposite material preparation, can solve the problems of absolute mixing and large particles, uneven powder particle size, easy particle agglomeration cost, etc., and achieve good plating effect and good plating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

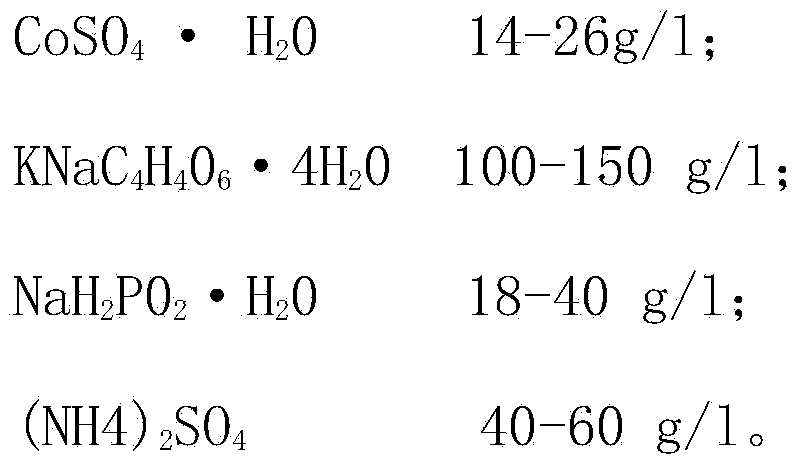

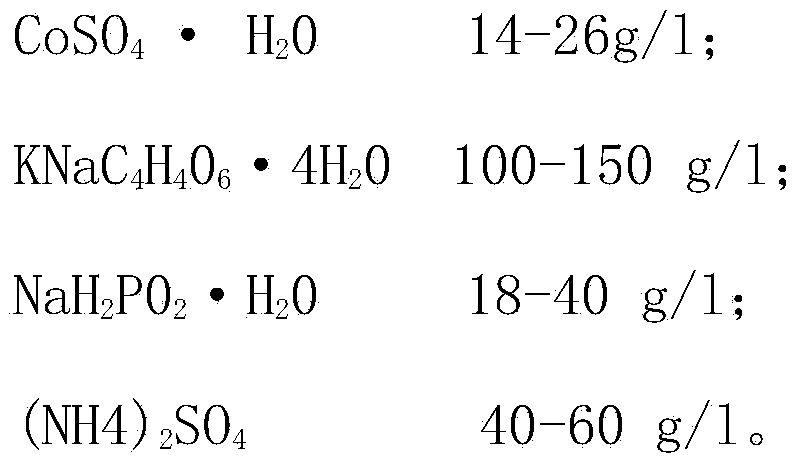

[0037] Take 10g of WC powder with an average size of 30nm and put it into 200ml of sensitizing solution, and perform ultrasonic sensitization treatment for 10 minutes. During the sensitization treatment, the frequency of ultrasonic waves is 35KHz, and the ultrasonic power is 100W; Wash the final WC powder until the lotion is colorless and transparent (about 10min). During ultrasonic cleaning, the ultrasonic frequency is 35KHz, and the ultrasonic power is 100W; then, under ultrasonic conditions, put the sensitized and cleaned WC powder into Activation treatment in 200ml activation solution for 10 minutes, ultrasonic activation, ultrasonic frequency 35KHz, ultrasonic power 100W; then under ultrasonic conditions, wash the activated WC powder with flowing distilled water until the washing liquid is colorless and transparent (about 10min ), during ultrasonic cleaning, the ultrasonic frequency is 35KHz, and the ultrasonic power is 100W; then put the activated and cleaned WC powder in...

Embodiment 2

[0039] Take 10g of WC powder with an average size of 100nm and put it into 300ml of sensitizing solution, and perform ultrasonic sensitization treatment for 10 minutes. During the sensitization treatment, the frequency of ultrasonic wave is 45KHz, and the ultrasonic power is 200W; Wash the final WC powder until the lotion is colorless and transparent (about 10min). During ultrasonic cleaning, the ultrasonic frequency is 45KHz, and the ultrasonic power is 200W; then, under ultrasonic conditions, put the sensitized and cleaned WC powder into Activation treatment in 300ml activation solution for 10min, ultrasonic activation, ultrasonic frequency 45KHz, ultrasonic power 200W; then under ultrasonic conditions, wash the activated WC powder with flowing distilled water until the lotion is colorless and transparent (about 10min ), during ultrasonic cleaning, the ultrasonic frequency is 45KHz, and the ultrasonic power is 200W; then put the activated and cleaned WC powder into 300ml of a...

Embodiment 3

[0041] Take 10g of WC powder with an average size of 100nm and put it into 400ml of sensitizing solution, and perform ultrasonic sensitization treatment for 10 minutes. During the sensitization treatment, the frequency of ultrasonic wave is 45KHz, and the ultrasonic power is 200W; Wash the final WC powder until the lotion is colorless and transparent (about 10min). During ultrasonic cleaning, the ultrasonic frequency is 45KHz, and the ultrasonic power is 200W; then, under ultrasonic conditions, put the sensitized and cleaned WC powder into Activation treatment in 300ml activation solution for 10min, ultrasonic activation, ultrasonic frequency 45KHz, ultrasonic power 200W; then under ultrasonic conditions, wash the activated WC powder with flowing distilled water until the lotion is colorless and transparent (about 10min ), during ultrasonic cleaning, the ultrasonic frequency is 45KHz, and the ultrasonic power is 200W; then put the activated and cleaned WC powder into 300ml of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com