Novel low-energy-consumption natural gas liquefaction technology

A technology of natural gas and low energy consumption, applied in the field of new natural gas liquefaction process, can solve the problems of large-scale mixed refrigeration compressor manufacturing difficulties, long cascade refrigeration process, and localized production difficulties, so as to optimize BOG separation process, reduce equipment investment, Strong ability to adapt to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

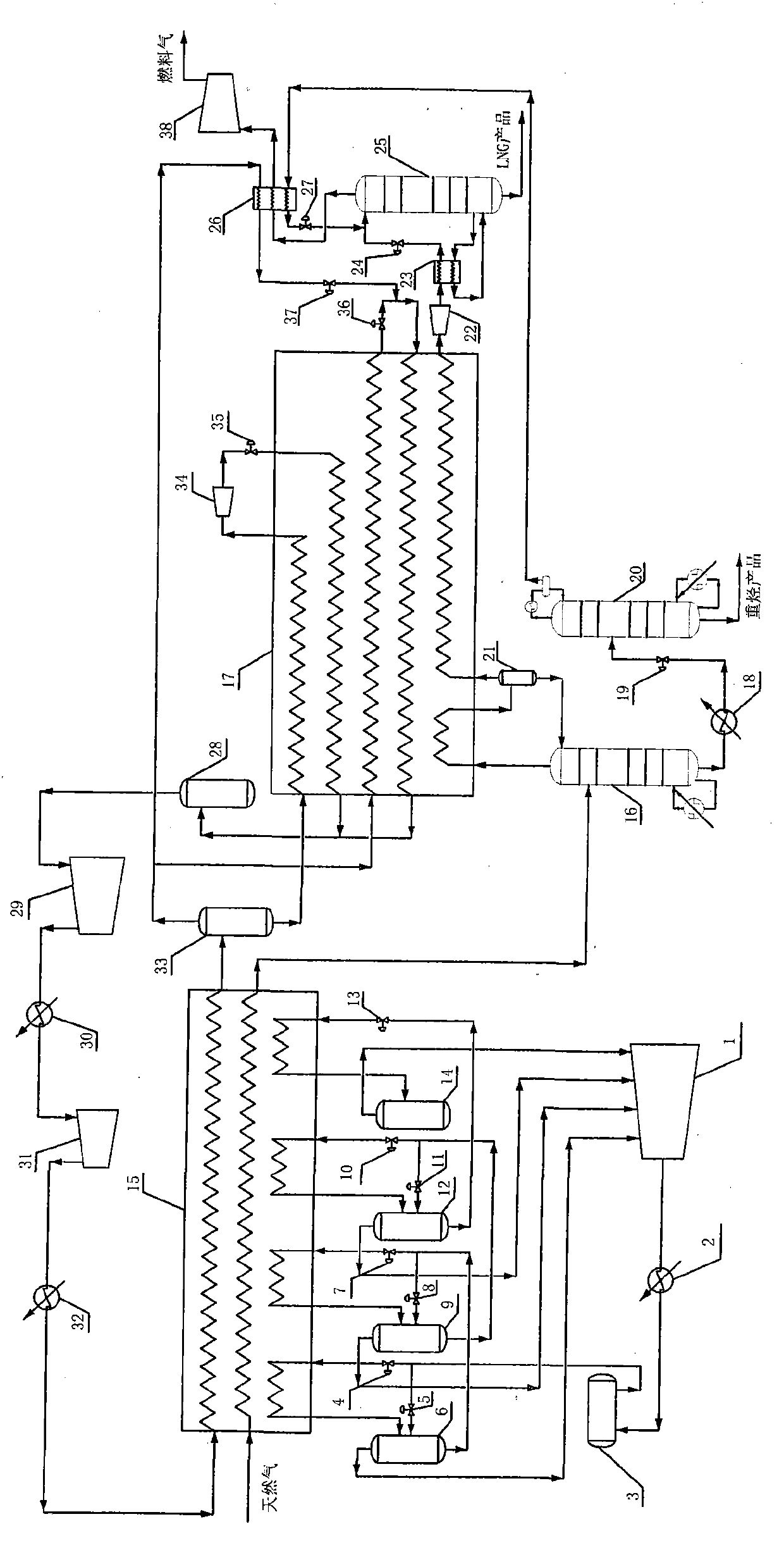

[0025] In this embodiment, the natural gas from the dehydration and mercury removal system enters the high-efficiency natural gas pre-cooling heat exchanger 15 to pre-cool the natural gas to -37°C. The pre-cooled natural gas enters the high-pressure heavy hydrocarbon separation tower 16, and the gas phase at the top of the tower enters the natural gas liquefaction The cryogenic heat exchanger 17 is cooled to -50°C and enters the top reflux tank 21 for gas-liquid separation. The liquid phase at the bottom of the tank is used as the reflux of the high-pressure heavy hydrocarbon separation tower, and the gas phase at the top of the tank enters the natural gas liquefaction cryogenic refrigerator 17 and is cooled to - 153°C, expand and depressurize to 0.46MPa.g through the natural gas liquid expander 22, enter the BOG separation tower reboiler 23 for heat exchange, and then depressurize to 0.024MPa.g through the throttle valve 24 and then enter the BOG separation tower 25; The liqui...

Embodiment 2

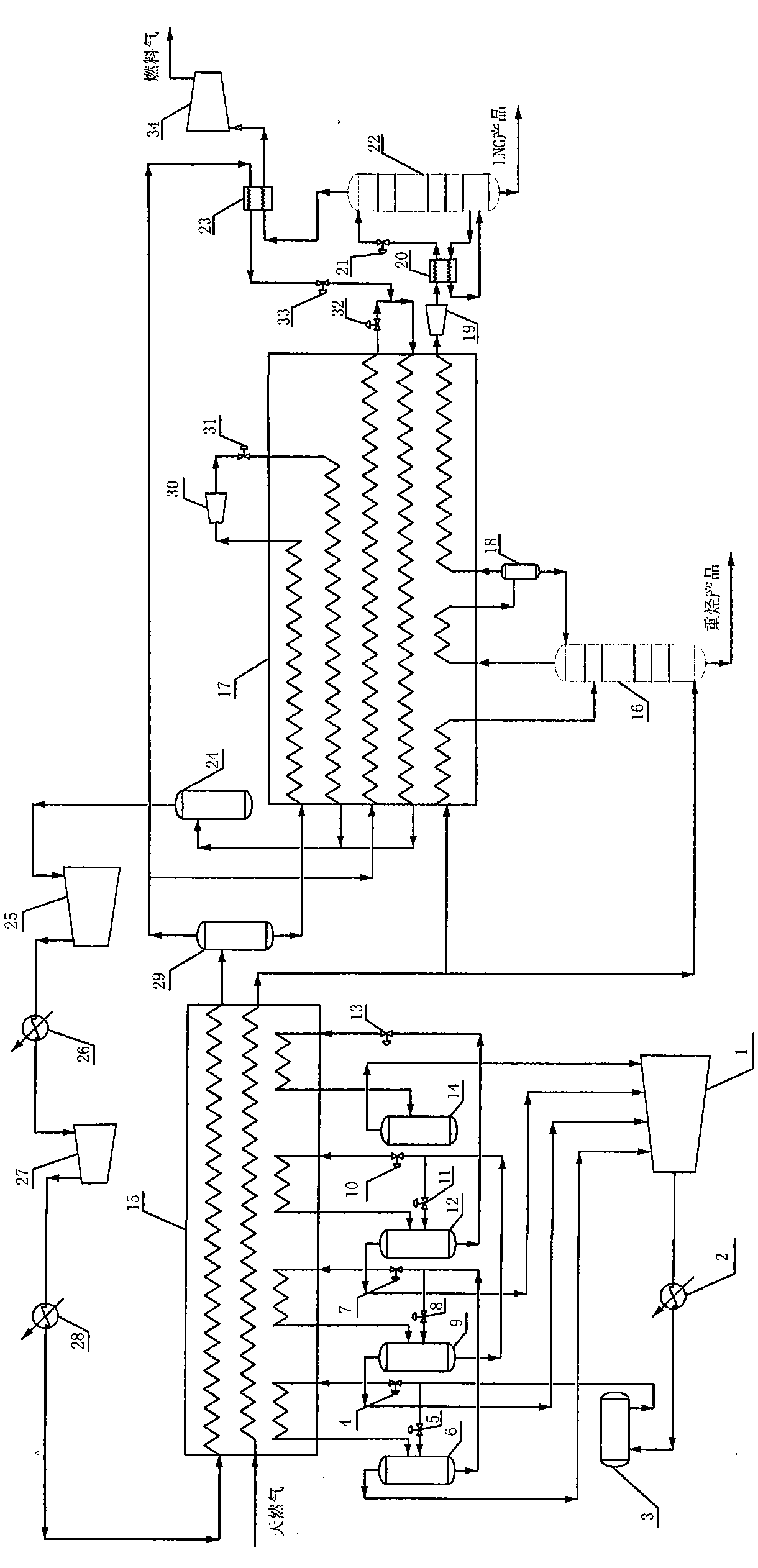

[0031] In this embodiment, the natural gas from the dehydration and mercury removal system enters the high-efficiency natural gas pre-cooling heat exchanger 15 to pre-cool the natural gas to -37°C. The pre-cooled natural gas is divided into two parts, and one part enters the heavy hydrocarbon separation tower from the tower kettle 16. The other part enters the natural gas liquefaction cryogenic heat exchanger 17 to cool to -55°C, and enters the heavy hydrocarbon separation tower 16 from the upper part of the tower; the gas phase at the top of the tower enters the natural gas liquefaction cryogenic heat exchanger 17, cools to -72°C, and enters the top of the tower The gas-liquid separation in the reflux tank 18, the liquid phase at the bottom of the tank is used as the reflux of the heavy hydrocarbon separation tower, the gas phase at the top of the tank enters the natural gas liquefaction cryogenic heat exchanger 17, is cooled to -153°C, and is expanded and depressurized to 0.46...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com