Light-emitting diode (LED) bulb lamp

A technology of LED bulb lamps and radiators, which is applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., and can solve the problems of light source, power supply damage, unsatisfactory heat dissipation effect, and high requirements for lamp body radiators. Achieve the effect of easy inspection and maintenance, simple and easy assembly process, and avoid heat superposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

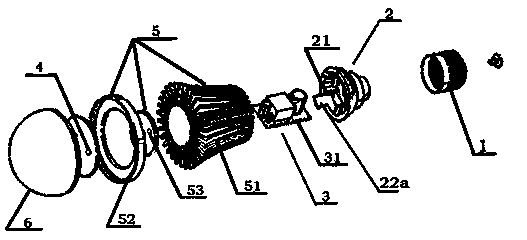

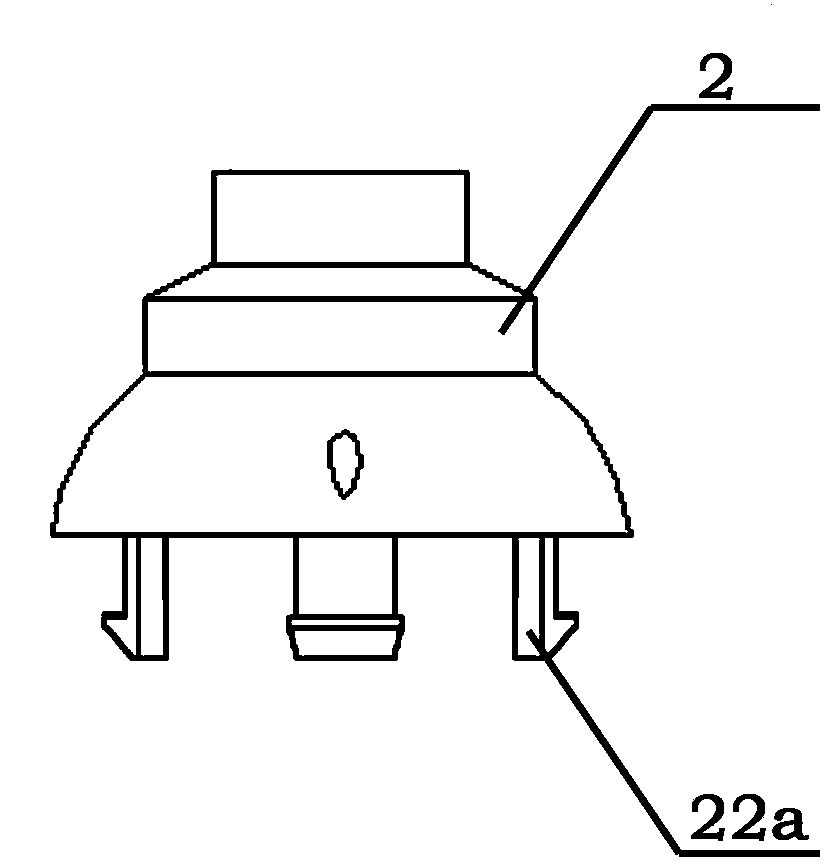

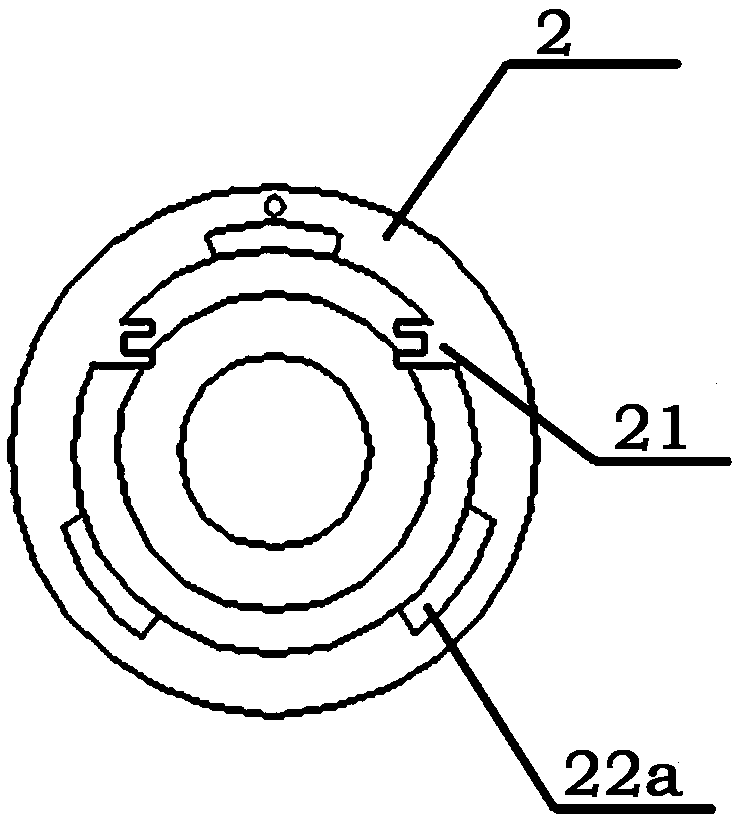

[0033] like figure 1 Shown is the LED bulb lamp of the present invention, comprising: a heat sink 5 with several heat sinks and a cavity in the middle; a light source element 4 arranged at the first mounting end 5a of the heat sink 5; a lens 6, Close to the light source element 4 and fixed on the radiator 5; the mounting seat 2 is arranged on the second installation end 5b of the radiator 5; the power supply 3 provides electric energy for the light source element 4; the lamp holder 1 is set On the mounting base 2, it is suitable for electrical connection with the lamp base; one end of the power supply 3 is fixed in the seat cavity of the mounting base 2, and the other end extends into the cavity of the radiator 5, suspended above the light source element 4 and not in contact with the heat sink 5 .

[0034] Wherein, the way of fixing the power supply 3 in the cavity of the mounting base 2 is not unique, as long as the fixing can be realized. In this embodiment, a specific imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com