A kind of horn tube for combing machine

A trumpet tube and combing machine technology, which is applied in the direction of combing machines, textiles, papermaking, and fiber processing, can solve problems such as deterioration of combed sliver, jamming of combed sliver, and influence on normal driving, so as to improve stability, The effect of improving the quality of combed sliver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

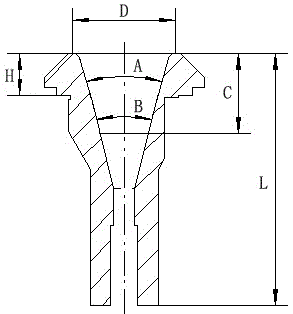

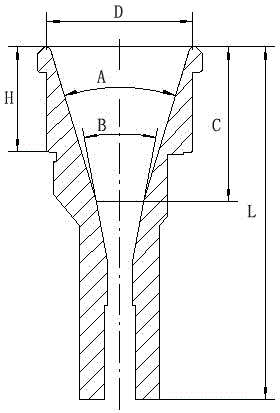

[0009] Such as figure 2 As shown, a combing machine passing cotton trumpet tube, the nozzle diameter D of the horn tube is φ30mm, the large angle A of the guide surface inside the tube is 33.72°, the small angle B of the guide surface inside the tube is 23°, and the height H of the tube head is 22.5° mm, the boundary C of the guide surface is 33mm, and the total length L of the tube is 75mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com