In-situ reaction type concrete protective agent

A concrete curing agent and concrete technology, applied in the field of building materials, can solve the problems of limited reaction degree, difficulty in guaranteeing, increase the strength of organic film formation, etc., and achieve the effects of simple construction method, few components, and prevention of water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

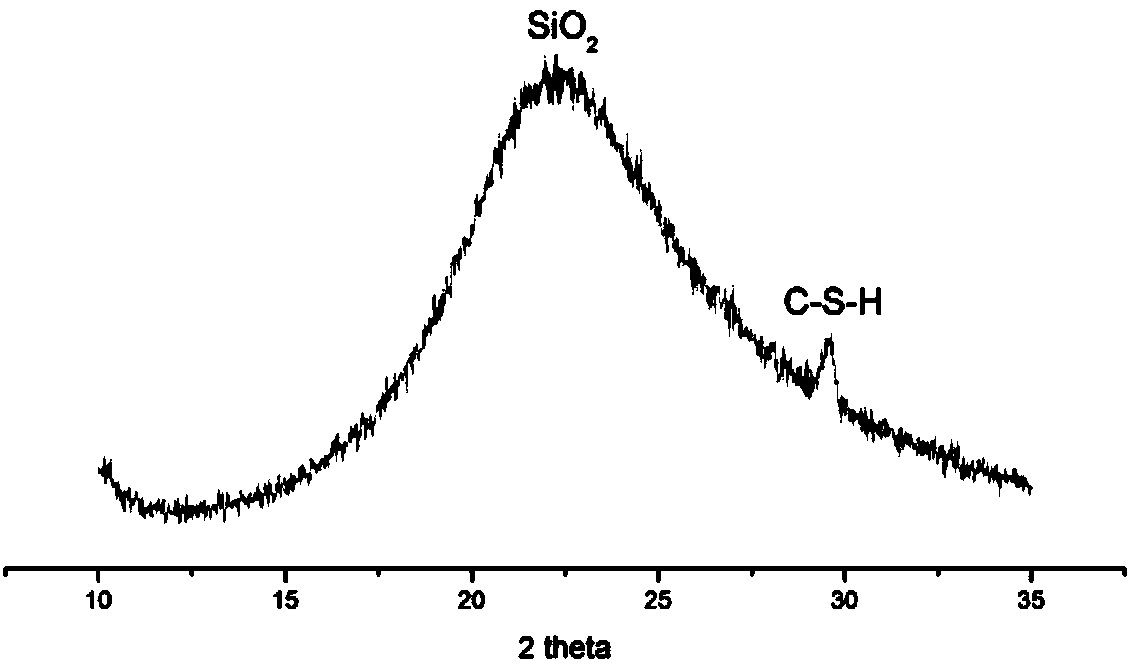

Image

Examples

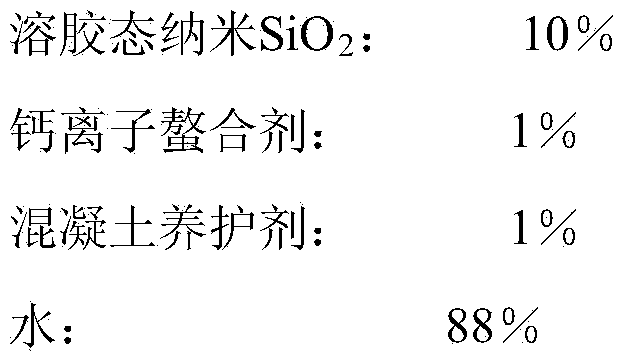

Embodiment 1

[0026] A kind of sol-state nano-SiO 2 or its precursors to protect the surface hardened concrete, the protective material components and their mass percentages are:

[0027]

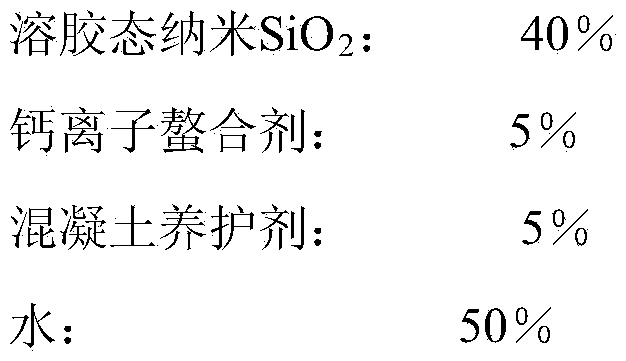

Embodiment 2

[0029] A kind of sol-state nano-SiO 2 or its precursors to protect the surface hardened concrete, the protective material components and their mass percentages are:

[0030]

Embodiment 3

[0032] A kind of sol-state nano-SiO 2 or its precursors to protect the surface hardened concrete, the protective material components and their mass percentages are:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com