Method for preparing nano-scale ZSM-5 molecular sieve by using coal ash

A technology of ZSM-5 and fly ash, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of high production cost of ZSM-5 molecular sieve, and achieve high-value utilization, Lower synthesis cost and better crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

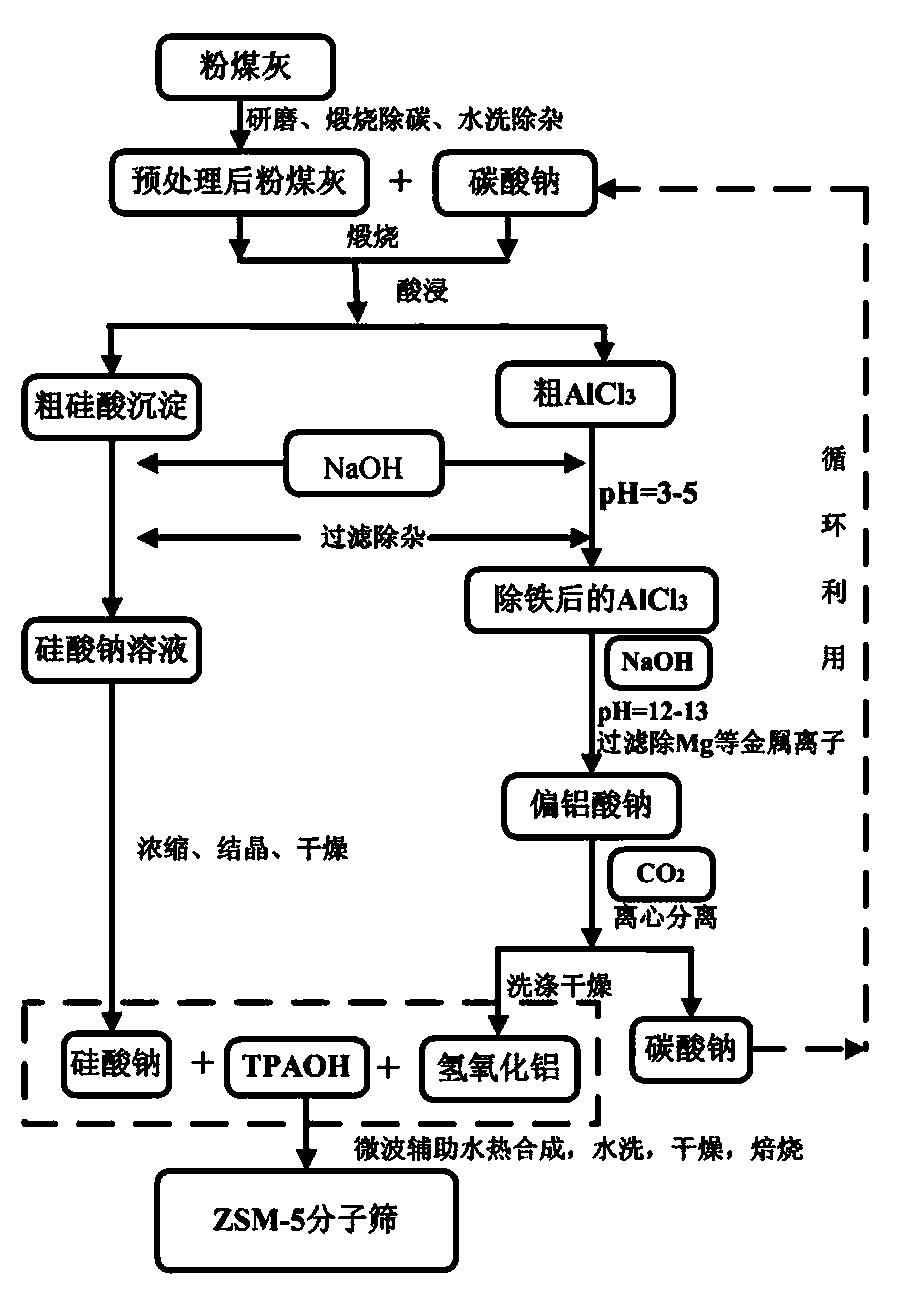

[0025] combine figure 2 , take fly ash collected on site as raw material, grind it into fine powder, pass through a 200-mesh sieve, take 100g of fine powder and place it in a muffle furnace, calcinate at 800°C for 2 hours, then burn it at a temperature of 75°C and a speed of 250r / Min was washed twice with water for 0.5 hours each time, and then the washing liquid was separated from the fly ash for solid-liquid separation. After separation, the solid was dried at 120°C for 5 hours for later use; the pretreated fly ash was mixed with Na 2 CO 3 The mass ratio of solids is 1:1 and mixed evenly. After roasting at 800°C for 2 hours, take it out and cool it to 25°C for later use; then impregnate the roasted product with 3mol / L HCl for 60 minutes, filter to remove insoluble matter, and obtain silica-rich gel and crude AlCl 3 solution. Adjust crude AlCl with 4% NaOH 3 pH value of the solution to 3.5, filtered to remove Fe(OH) 3 , the filtrate continued to add NaOH dropwise until...

Embodiment 2

[0027] Use fly ash collected on site as raw material, grind it into fine powder, pass through a 200-mesh sieve, put 100g of fine powder in a muffle furnace, calcinate at 750°C for 3 hours, then wash with water at 50°C and 200r / min for 2 hours time, 1 hour each time, and then carry out solid-liquid separation between the washing solution and the fly ash, and dry the solid at 120°C for 5 hours after separation; the pretreated fly ash and Na 2 CO 3 The mass ratio of solids is 1:1.2 and mixed evenly. After roasting at 750°C for 2.5 hours, take it out and cool it to 25°C for later use; then impregnate the roasted product with 2.5mol / L HCl for 70 minutes, filter to remove insoluble matter, and obtain silicon-rich gel and Crude AlCl 3 solution. Adjust crude AlCl with 8% NaOH 3 pH value of the solution to 3, filtered to remove Fe(OH) 3 , the filtrate continued to add NaOH dropwise until the precipitation in the filtrate no longer increased, and the Mg(OH) was removed by filtration...

Embodiment 3

[0029] Use fly ash collected on site as raw material, grind it into fine powder, pass through a 200-mesh sieve, put 100g of fine powder in a muffle furnace, calcinate at 750°C for 3 hours, then wash with water at 50°C and 200r / min for 2 hours time, 1 hour each time, and then carry out solid-liquid separation between the washing solution and the fly ash, and dry the solid at 120°C for 5 hours after separation; the pretreated fly ash and Na 2 CO 3 The mass ratio of solids is 1:1.2 and mixed evenly. After roasting at 750°C for 2.5 hours, take it out and cool it to 25°C for later use; then impregnate the roasted product with 2.5mol / L HCl for 70 minutes, filter to remove insoluble matter, and obtain silicon-rich gel and Crude AlCl 3 solution. Adjust crude AlCl with 8% NaOH 3 pH value of the solution to 3, filtered to remove Fe(OH) 3 , the filtrate continued to add NaOH dropwise until the precipitation in the filtrate no longer increased, and the Mg(OH) was removed by filtration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com