Wine bottle packing box

A technology for packaging boxes and wine bottles, which is applied in the directions of transportation and packaging, packaging of vulnerable items, and types of packaging items, which can solve the problems of poor anti-collision ability, increased damage, waste of leftover materials, etc., and achieve anti-collision and anti-squeeze. Better performance, better anti-collision and anti-extrusion performance, better shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with accompanying drawing :

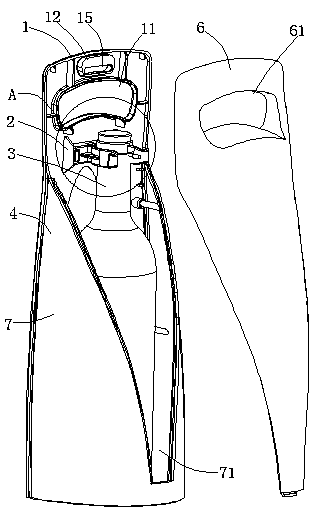

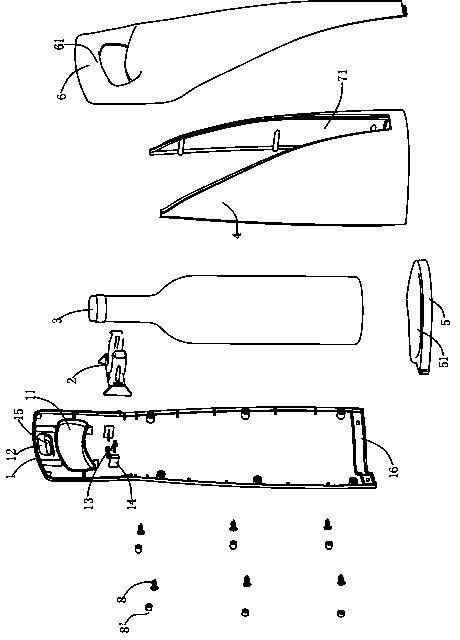

[0032] The reference signs in the drawings are: rear case 1, rear case handle 11, clamping block 12, buckle clip hook 13, buckle clip limit block 14, clip hole 15, rear case groove 16, buckle clip 2 , wine bottle 3, front case 4, front case groove 42, front case lower block 43, bottom plate 5, recess 51, front cover 6, front cover handle 61, front cover upper hook 62, front cover lower card Hook 63, shell 7, opening 71, screw 8, plug cap 8', cavity 9.

[0033] Such as Figure 1 to Figure 6 As shown, a wine bottle packaging box of the present invention includes a housing 7, wherein a cavity 9 capable of accommodating the wine bottle 3 is provided inside the housing 7; The buckle 2; the front side of the housing 7 is provided with an opening 71 with a wide top and a narrow bottom, and the opening 71 is provided with a front cover 6 whose shape matches the openin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com