Quantitative packing scale

A quantitative packaging and packaging bag technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve problems such as low efficiency and poor precision, and achieve the effects of high automation, improved efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

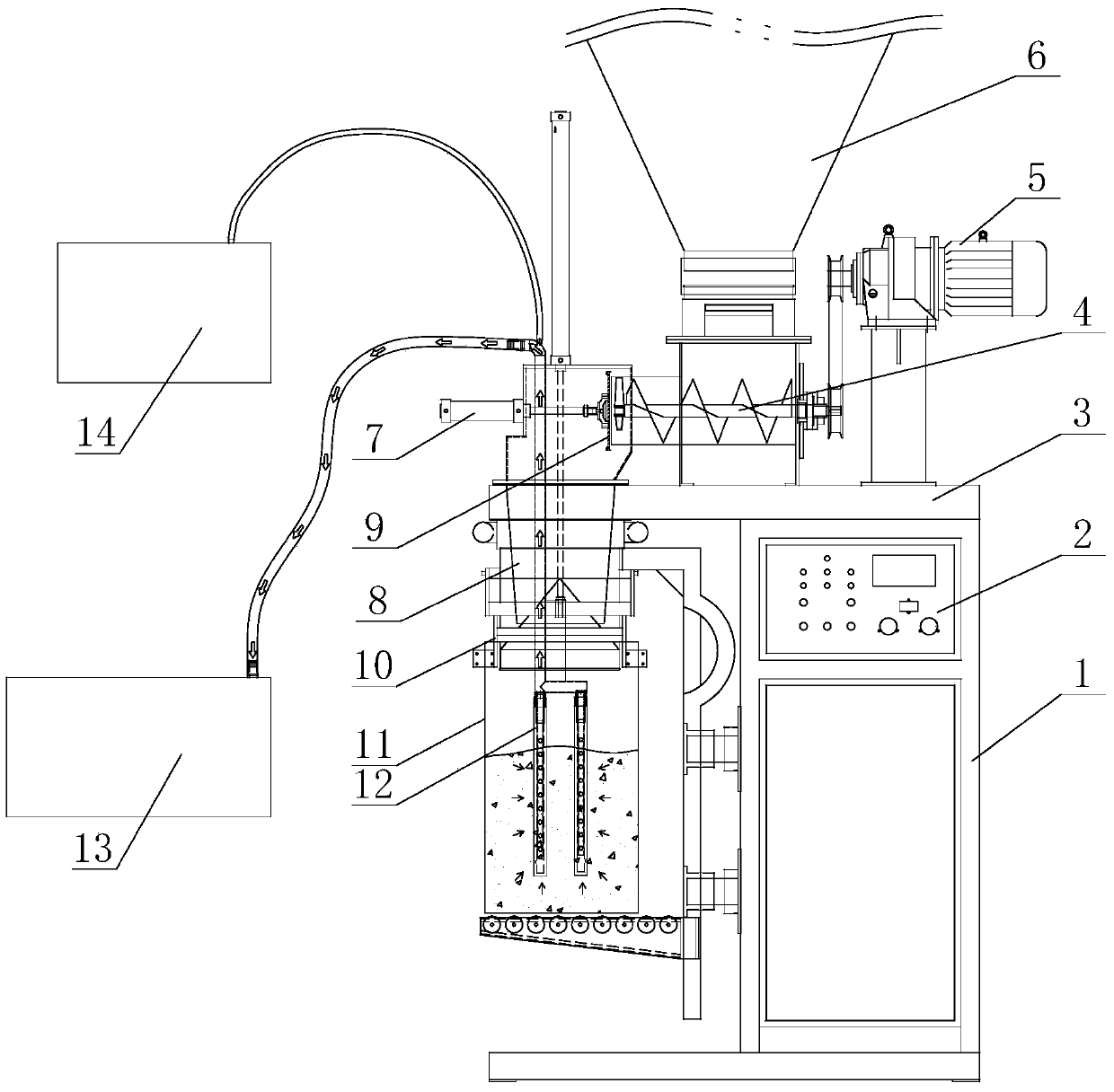

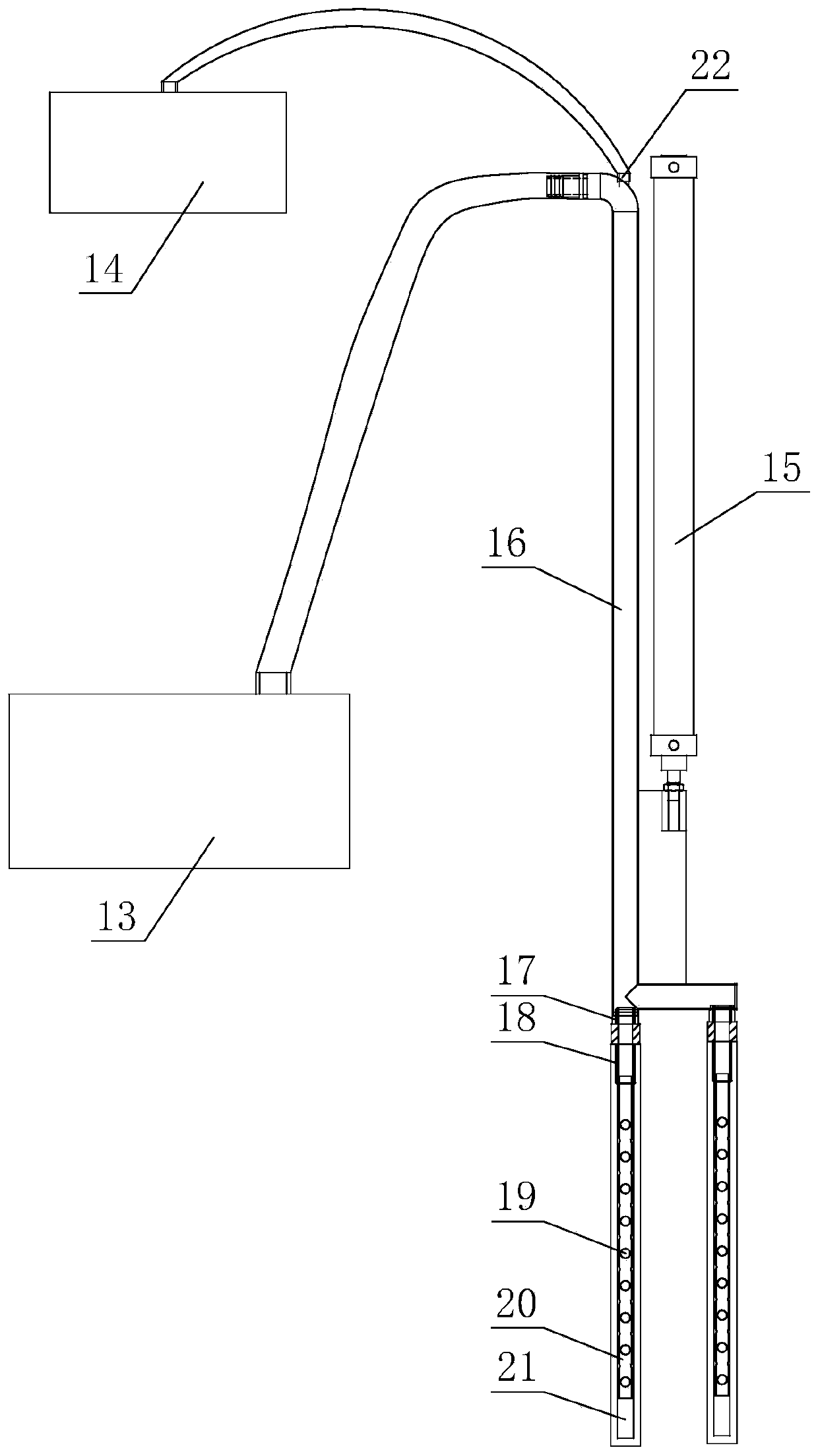

[0016] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0017] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of a quantitative packaging scale of the present invention; figure 2 It is a structural schematic diagram of a negative pressure degassing device of the present invention. In this embodiment, a quantitative packaging scale includes a frame 1, a negative pressure degassing device 12 and an operation panel installed on the frame 1, the upper end of the frame 1 is connected with a table 3, and the table 3 The right end is provided with a screw feeder 4 driven by a frequency conversion motor 5, the feed port of the screw feeder 4 is connected to the silo 6, and the discharge port is provided with a disc cover door 9 driven by a blocking cylinder 7 , the left end of the table top 3 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com