Composite packaging bag for beverages and production method of composite packaging bag

A composite packaging bag and production method technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of poor product flexibility, poor fresh-keeping performance, large expansion space, etc., and achieve good air tightness, Low cost and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: The present invention is used for the preparation of the composite packaging bag of beverage food

[0024] Take 54.2kg of low-density polyethylene, 43.8kg of biaxially oriented polyamide, and 2kg of polyvinylidene chloride.

[0025] The production method is as follows:

[0026] (1) Use low-density polyethylene as the raw material, put it into the reactor, and carry out the polymerization reaction under the action of the initiator under high-pressure compression. The material coming out of the reactor is removed by the separator to form a film after the unreacted low-density polyethylene ;

[0027] (2) Dry the biaxially stretched polyamide through raw materials→melt extrusion→cooling cast sheet→thickness measurement of cast sheet→simultaneous biaxial stretching→heat setting;

[0028] (3) Coat polyvinylidene chloride to 2.0 microns with a concave roller, and heat, dry and solidify. The drying tunnel is divided into three sections. The temperatures of the t...

Embodiment 2

[0031] Embodiment 2: the present invention is used for the preparation of the composite packaging bag of beverage food

[0032] Take 57kg of low-density polyethylene, 40.5kg of biaxially oriented polyamide, and 2.5kg of polyvinylidene chloride.

[0033] The production method is as follows:

[0034] (1) Use low-density polyethylene as the raw material, put it into the reactor, and carry out the polymerization reaction under the action of the initiator under high-pressure compression. The material coming out of the reactor is removed by the separator to form a film after the unreacted low-density polyethylene ;

[0035] (2) Dry the biaxially stretched polyamide through raw materials→melt extrusion→cooling cast sheet→thickness measurement of cast sheet→simultaneous biaxial stretching→heat setting;

[0036] (3) Coat the polyvinylidene chloride to 2.5 microns with a concave roller, and heat it to dry and solidify. The drying tunnel is divided into three sections, and the temperat...

Embodiment 3

[0039] The mensuration of embodiment 3 index parameters

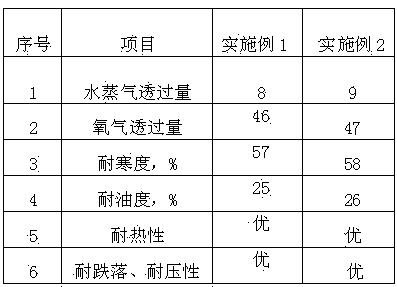

[0040] 1. Enterprise standards for technical parameters of composite packaging bags for beverages and foods are shown in Table 1:

[0041]

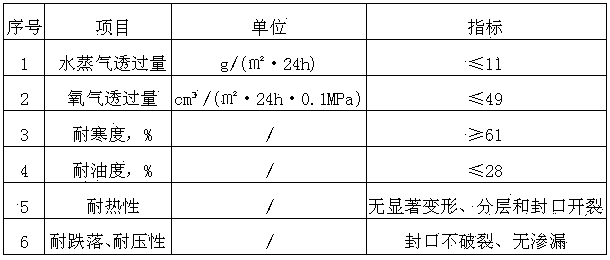

[0042] 2. The technical parameters of the composite packaging bag for beverages and foods prepared in Examples 1 and 2 are shown in Table 2:

[0043]

[0044] As can be seen from the comparison of Table 2 and Table 1, the technical parameters of the composite packaging bag for beverages and foods of the present invention are better than the standard parameters of the enterprise, especially that of Example 1 is better than the standard parameters.

[0045] For the production of this composite packaging bag, first of all, it is necessary to design the packaging style for industrial mass production, and according to the packaging style, make various shapes of packaging bags through pre-filming, printing, compounding, curing, cutting, molding and other processes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com