Flotation reagent for copper-nickel sulfide ores

A copper-nickel sulfide ore and flotation agent technology, applied in flotation, solid separation, etc., can solve the problems of negative impact on flotation concentrate grade, large environmental pollution, low recovery rate, etc.

Active Publication Date: 2013-12-11

LANZHOU UNIVERSITY

View PDF7 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

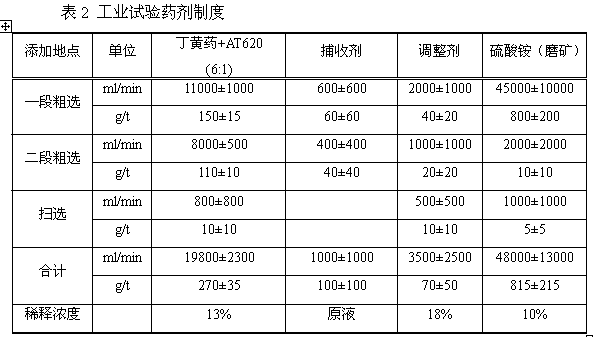

At present, the most widely used copper-nickel sulfide collectors are xanthate, black powder, mercaptan, etc., but although the collection capacity of these collectors is good, their selectivity is generally low, so that the concentrate grade is low. , high magnesium oxide content, and bring a series of problems to the smelting; the activation regulator used in flotation is copper sulfate, although copper sulfate has a certain activation effect on copper-nickel sulfide ore, but its effect on the grade band of flotation concentrate to some negative impact

The flotation of copper-nickel sulfide ore by these conventional agents generally has the disadvantages of low recovery rate, low concentrate grade, high magnesium oxide content, unstable flotation index in winter, large amount of agents, low resource utilization rate, and large environmental pollution. , it is impossible to realize efficient, economical and clean utilization of copper-nickel sulfide ore

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

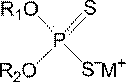

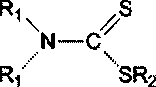

The invention discloses a flotation reagent for copper-nickel sulfide ores. The flotation reagent comprises, by weight, 35-65 parts of alkyl-dithiocarbamate, 5-25 parts of second oil, 5-10 parts of terpilenol, 15-20 parts of hydrazide-group-dithio-formic ether and 5-15 parts of dialkyl-dithiophosphate. The flotation reagent is good in selection, strong in collecting capacity and good in bubble stability, especially has a stronger collecting effect on the copper-nickel sulfide ores, can achieve separation of valuable minerals from gangue minerals such as serpentine and olivine within the pH value of 7-10, and can effectively improve concentrate grade and the recovery rate.

Description

technical field The invention belongs to the field of mineral flotation, in particular to a flotation agent for copper-nickel sulfide ore. Background technique Nickel is an important non-ferrous metal, which is widely used in steel, electronic technology, aerospace technology and other industries. In recent years, its consumption has been increasing. Domestic nickel metal has been unable to meet the needs of domestic development, and it needs to be imported in large quantities from abroad every year. nickel metal material. Copper-nickel sulfide ore is an important raw material for providing nickel metal materials, but with continuous mining, the ore becomes poor, fine, and miscellaneous, which is not conducive to processing, which brings new challenges to the beneficiation work, so the development of new beneficiation technology and The new beneficiation method is an important means to solve refractory minerals. Flotation agents are an important part of flotation, improvi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B03D1/018B03D101/02

Inventor 许鹏飞徐国强罗永春胡秀琴王瑶曹建

Owner LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com