Piezoelectric vibrating reed, piezoelectric vibrator, method for manufacturing piezoelectric vibrating reed, and method for manufacturing piezoelectric vibrator

A technology of piezoelectric vibrating plate and manufacturing method, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, piezoelectric devices/electrostrictive devices, etc. , can solve the problems of complex electrode structure, increase the damage of the piezoelectric vibrating piece, increase the electrode manufacturing process, etc., achieve the effect of joint strength and stability, facilitate miniaturization, and improve joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

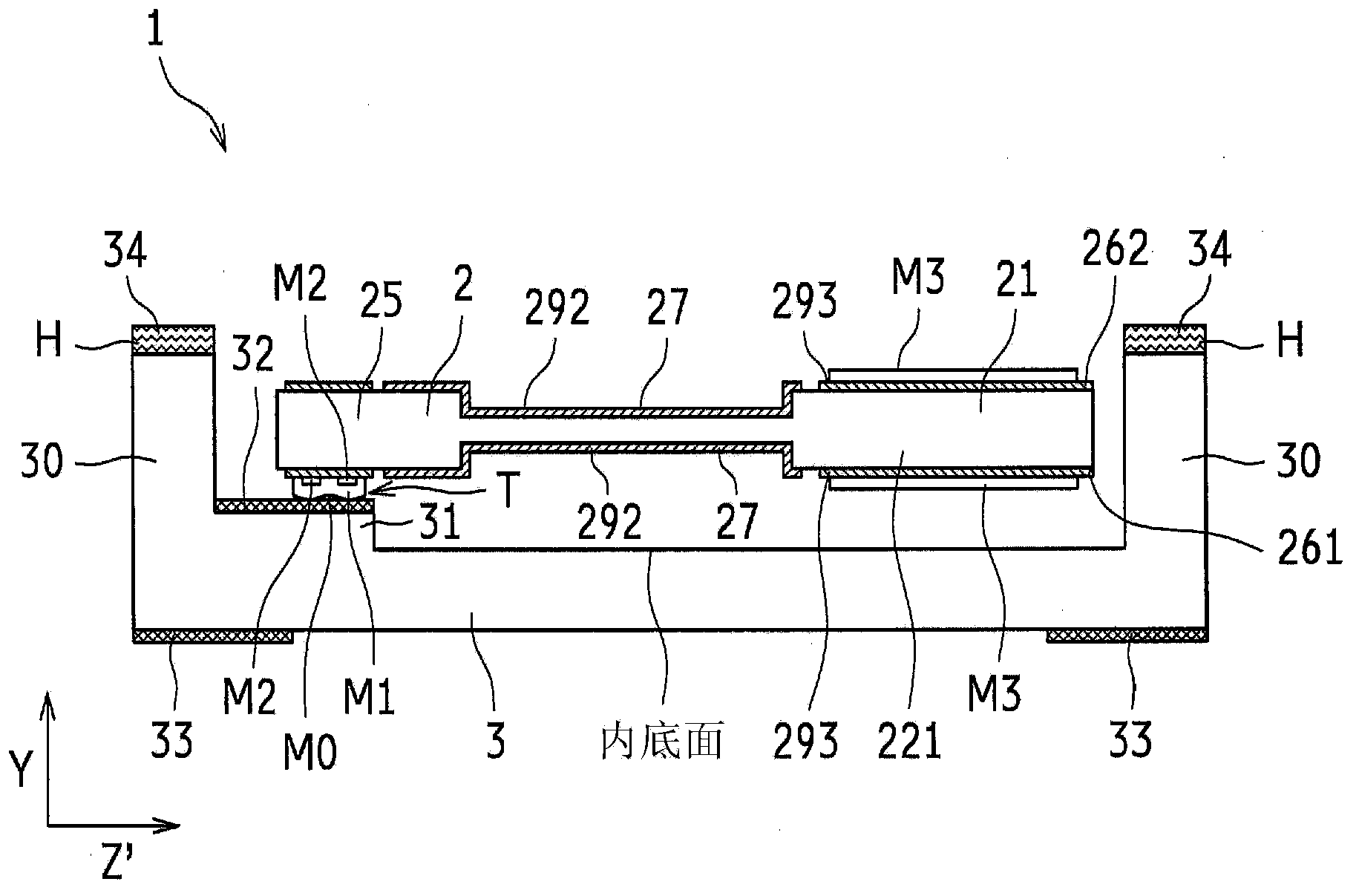

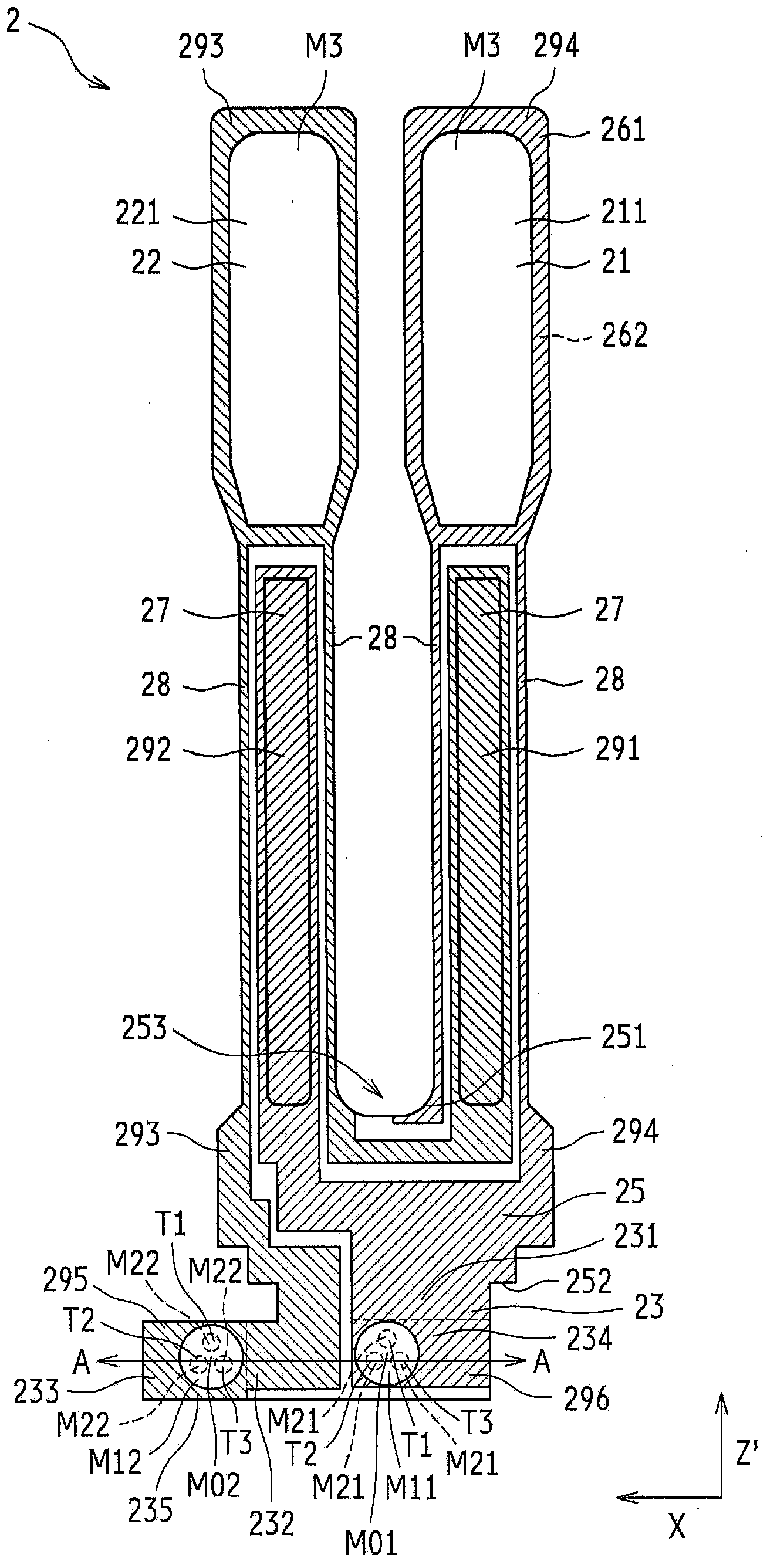

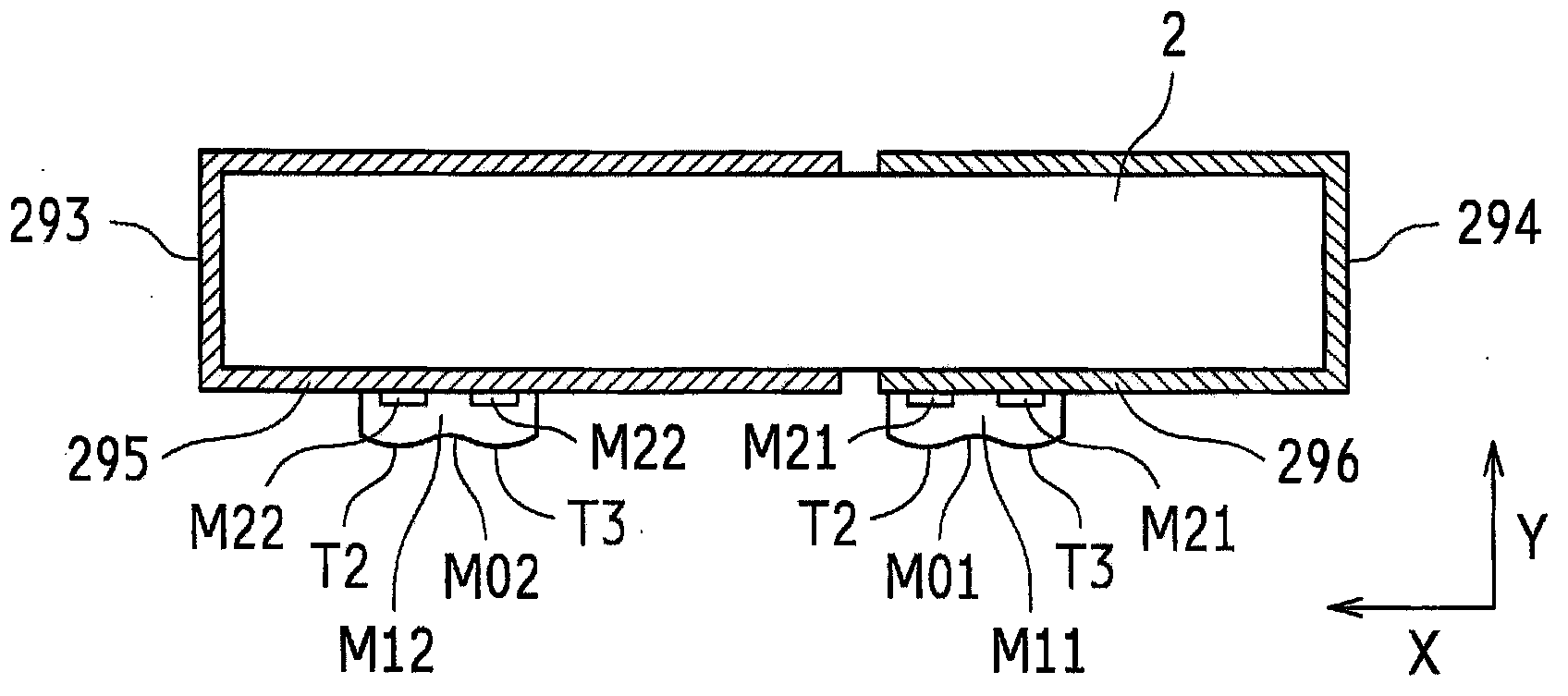

[0080] Hereinafter, as a piezoelectric vibrating piece, a tuning-fork type crystal vibrating piece is taken as an example and described with reference to the drawings. In the tuning-fork type crystal resonator 1 used in this embodiment, the base 3 and the lid (not shown) are bonded by a sealing member H to form a housing. Specifically, the tuning-fork-type crystal vibrating piece 2 is bonded to the electrode pad 32 of the base 3 with an upper opening through the first metal film M1 plated with bumps or the like, and the plate-shaped cover is bonded through the sealing member H. On the end face of the opening, the opening (opening) of the base 3 is sealed. Here, in the present embodiment, the nominal frequency of the tuning-fork crystal resonator 1 is 32.768 kHz. In addition, the nominal frequency is only an example, and other frequencies may be used.

[0081] The base 3 is an insulating container made of ceramic material or glass material. In this embodiment, for example, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com