Method for preparing L-methionine

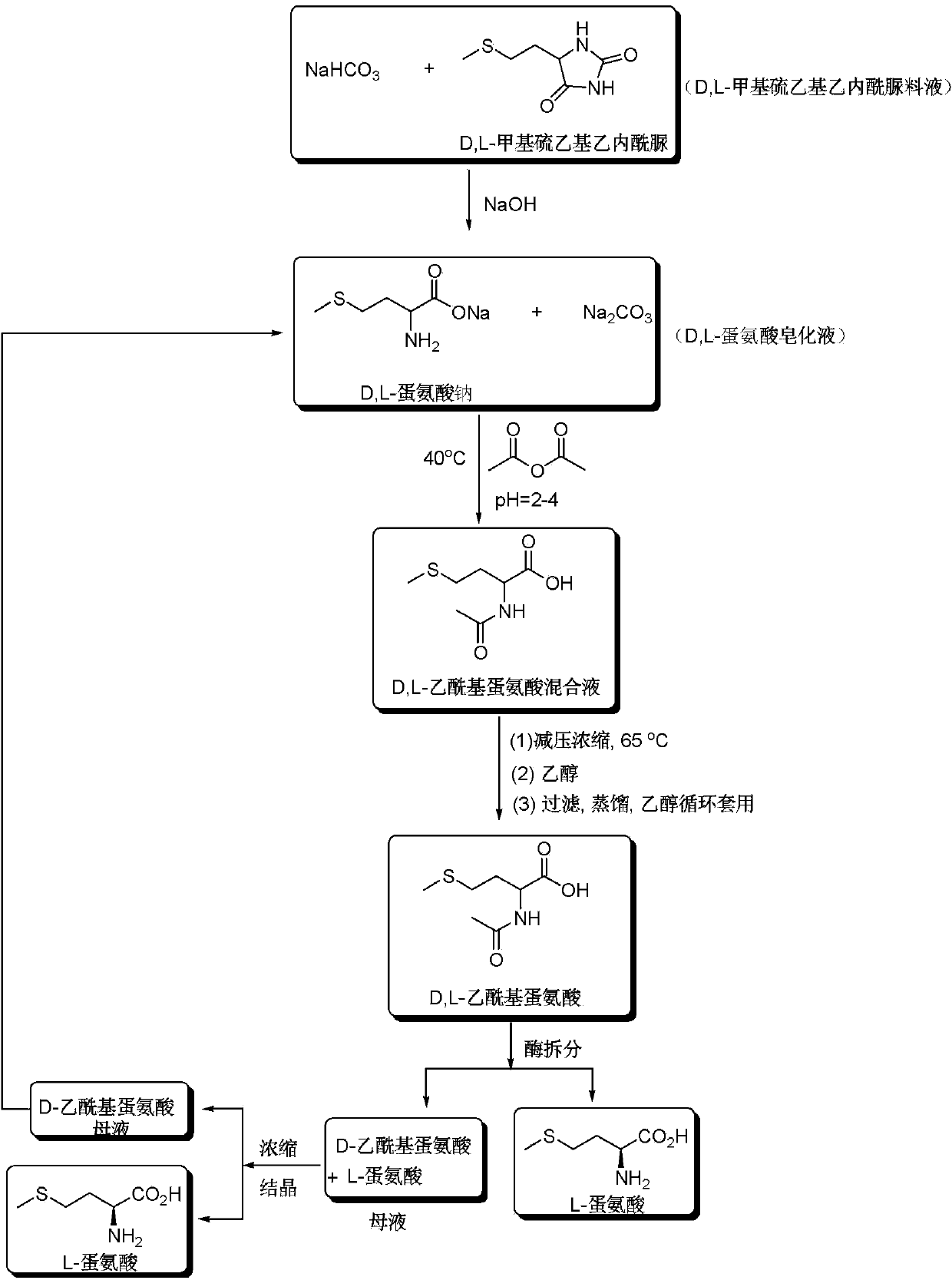

A technology of methionine and acetylmethionine, which is applied in the field of using D,L-methionine to produce saponification liquid and jointly prepare L-methionine, which can solve the problems of low recycling rate of waste liquid, complicated operation, environmental pollution of waste liquid, etc., and achieve production cost Reduced, low operating costs, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

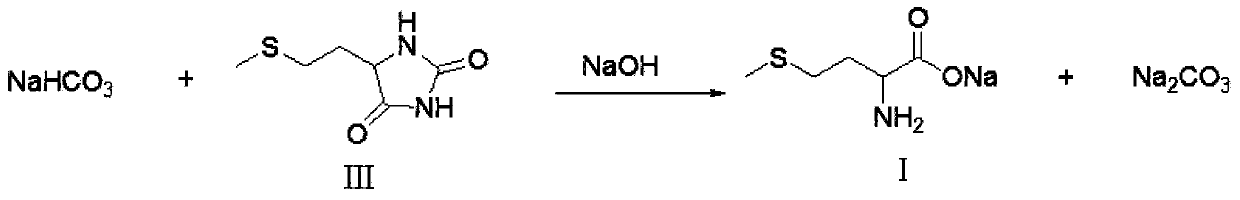

[0042] The preparation of embodiment 1 saponification liquid

[0043] After the 5-(2-methylthioethyl)-hydantoin (Ziguang Tianhua Methionine Co., Ltd.) is decolorized with activated carbon, sodium hydroxide is added, and the hydrolysis reaction system is heated to 130°C until fully hydrolyzed. Obtain a saponified solution. The composition of the saponification liquid was analyzed, and it was composed of the following components: D, L-methionine sodium 15% by mass, sodium carbonate 10% by mass, and the balance was water. The saponified solution obtained by hydrolysis can be directly used in the following examples to produce D,L-acetylmethionine.

Embodiment 2

[0044] The preparation of embodiment 2 saponification liquid

[0045] After the 5-(2-methylthioethyl)-hydantoin (Ziguang Tianhua Methionine Co., Ltd.) is decolorized with activated carbon, sodium hydroxide is added, and the hydrolysis reaction system is heated to 150°C until fully hydrolyzed. Obtain a saponified solution. The composition of the saponification liquid was analyzed, and it was composed of the following components: D, L-methionine sodium 19% by mass, sodium carbonate 13% by mass, and the balance was water. The saponified solution obtained by hydrolysis can be directly used in the following examples to produce D,L-acetylmethionine.

Embodiment 3

[0046] Embodiment 3 Acetylation of saponified liquid

[0047] Get 200 kilograms of the saponified solution after the decolorization mentioned in Example 1, slowly add 27 kilograms of acetic anhydride dropwise in the saponified solution, carry out acetylation reaction, control reaction temperature at 45 ℃, mainly control the rate of addition in the reaction process to avoid producing Too many bubbles, when the volume of acetic anhydride is dropped to 1 / 2, a large number of carbon dioxide bubbles will be generated; the reaction time is 5 hours, and D, L-acetylmethionine sodium will be generated.

[0048] The reaction process was observed by thin-layer chromatography, the developer was n-butanol: water: acetic acid = 4:1:1, the chromogenic agent was ninhydrin chromogenic method, and the chromatographic plate was silica chromatographic plate . The acetylation rate of D,L-methionine was monitored to be 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com