Method for extracting succinic acid from fermentation broth through two aqueous phase extraction

A fermentation broth and succinic acid technology, applied in the separation/purification of carboxylic acid compounds, etc., can solve the problems of low efficiency, high cost, difficulty in removing protein and glucose, etc., and achieve low energy consumption and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

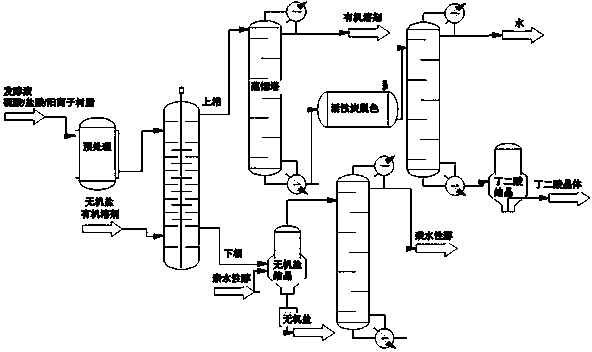

Method used

Image

Examples

Embodiment 1-5

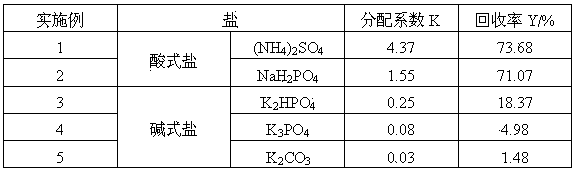

[0015] Example 1-5 Comparison of Extraction of Succinic Acid with Acid Salt and Basic Salt

[0016] Experimental conditions: take 4g of different acid salts ((NH 4 ) 2 SO 4 , NaH 2 PO 4 ) and basic salts (K 2 HPO 4 、K 3 PO 4 、K 2 CO 3 ) were dissolved in 50g / L succinic acid solution (simulated fermentation broth), and then 12g acetone was added. Shake for 3 minutes, and stand still for 8 hours to separate phases, respectively measure the volume of the upper and lower phases and the content of succinic acid, and calculate the distribution coefficient K and recovery rate Y of succinic acid; the results are shown in Table 1;

[0017] Table 1: Comparison of extraction of succinic acid with basic and acidic salts

[0018]

[0019] So choose to add acid salt.

Embodiment 6-10

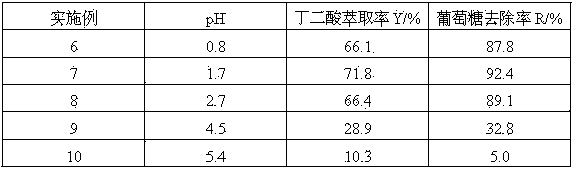

[0020] The extraction situation of succinic acid in the fermented liquid under the different pH conditions of embodiment 6-10

[0021] Experimental conditions: adjust the fermented liquid of succinic acid to different pH values with sulfuric acid, then get 12g fermented liquid with different pH respectively, add 4g (NH 4 ) 2 SO 4 Dissolve, then add 4g of acetone and shake for 3min, let stand for 8h to separate the phases, measure the volume of the upper and lower phases and the content of succinic acid and glucose respectively, calculate the extraction rate Y of succinic acid and the removal rate R of glucose, the results are shown in Table 2;

[0022] Table 2: Extraction of succinic acid under different pH conditions

[0023]

[0024] It can be seen that it is appropriate to choose a pH of 1~3 for the fermentation broth.

Embodiment 11-13

[0025] Examples 11-13 are different (NH 4 ) 2 SO 4 Extraction of succinic acid fermentation broth under concentration conditions

[0026] Experimental conditions: adjust the pH value of the fermentation broth to 2.0 with sulfuric acid, take 3 parts of 10g fermentation broth, add different masses of ammonium sulfate (3g, 4g, 5g) respectively, add deionized water so that the mass of each part is 15g, dissolve , then add 5g of acetone, shake for 3min, stand still for 8h to separate the phases, measure the volume of the upper and lower phases respectively, measure the content of succinic acid, glucose, protein and cells, and calculate the extraction rate Y of succinic acid and glucose, cells and protein The removal rate, the results are shown in Table 3;

[0027] Table 3 is different (NH 4 ) 2 SO 4 Extraction of succinic acid fermentation broth under concentration conditions

[0028]

[0029] It can be seen that the final concentration fraction w / w of salt is 15%~25% is mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com