A low-temperature preparation method of nd2-xcexcuo4-delta superconducting nano ceramic powder

A nano-porcelain and superconducting technology is applied in the field of preparation of Nd1.85Ce0.15CuO4-δ superconducting nano-porcelain, which can solve the problems of consumption, inability to synthesize nano-powder, large energy, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

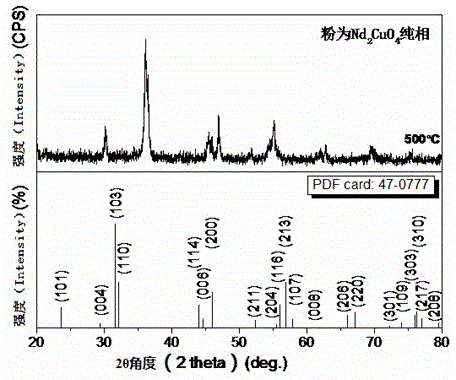

Embodiment 1

[0025] (1) Nd(NO 3 ) 3 ·nH 2 O, Cu(NO 3 ) 2 ·3H 2 O and EDTA (ethylenediaminetetraacetic acid) are weighed according to the molar ratio of Nd:Ce:Cu:EDTA is 2:1:3;

[0026] (2) According to the liquid-solid ratio (L / Kg) of 5:1, place the EDTA prepared in step (1) in deionized water, and add ethylenediamine at the same time to adjust the pH value to 4 to obtain a mixed solution;

[0027] (3) Add the Nd(NO 3 ) 3 ·nH 2 O and Cu(NO 3 ) 2 ·3H 2 0, while adding ethylenediamine to adjust the pH value to be 8, to obtain a mixture;

[0028] (4) Heat the mixture obtained in step (3) to reflux at 60°C for 1 hour to obtain a sol, then heat, evaporate and concentrate for 7 hours to obtain a gel, and dry the gel in an oven at 120°C under normal pressure to obtain a dry gel;

[0029] (5) Calcining the xerogel obtained in step (4) at 600°C for 8 hours in an air atmosphere to obtain Nd 2 CuO 4-δ Superconducting nano ceramic powder.

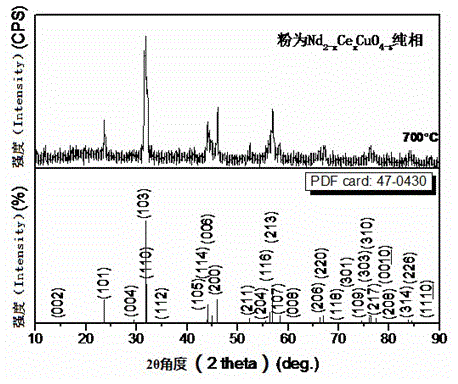

Embodiment 2

[0031] (1) Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and EDTA (ethylenediaminetetraacetic acid) are weighed according to the molar ratio of Nd:Ce:Cu:EDTA is 1.85:0.15:1:3;

[0032] (2) According to the liquid-solid ratio (L / Kg) of 20:1, place the EDTA prepared in step (1) in deionized water, and add ethylenediamine at the same time to adjust the pH value to 6 to obtain a mixed solution;

[0033] (3) Add the Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 0, while adding ethylenediamine to adjust the pH value to 6, to obtain a mixture;

[0034] (4) Heat the mixture obtained in step (3) to reflux at 75°C for 4 hours to obtain a sol, then heat, evaporate and concentrate for 6 hours to obtain a gel, and dry the gel in an oven at 90°C under normal pressure to obtain a dry gel;

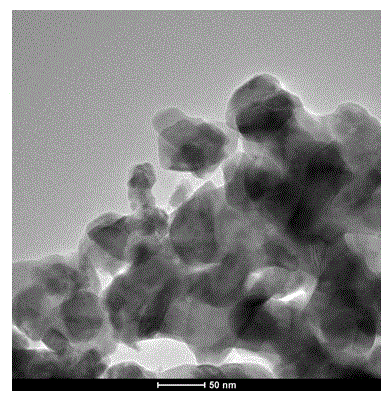

[0035] (5) Calcinate the xerogel obtained in step (4) at 700°C for 8 hours in an air atmosphere to obtain Nd 1.85 Ce 0.15 CuO 4-δ Superconducting nano...

Embodiment 3

[0037] (1) Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and EDTA (ethylenediaminetetraacetic acid) are weighed according to the molar ratio of Nd:Ce:Cu:EDTA is 1.83:0.17:1:3;

[0038] (2) According to the liquid-solid ratio (L / Kg) of 40:1, place the EDTA prepared in step (1) in deionized water, and add ethylenediamine at the same time to adjust the pH value to 8 to obtain a mixed solution;

[0039] (3) Add the Nd(NO 3 ) 3 ·nH 2 O, Ce(NO 3 ) 3 ·6H 2 O and Cu(NO 3 ) 2 ·3H 2 0, while adding ethylenediamine to adjust the pH value to 10, to obtain a mixture;

[0040] (4) Heat the mixture obtained in step (3) to reflux at 80°C for 2 hours to obtain a sol, then heat, evaporate and concentrate for 3 hours to obtain a gel, and dry the gel in an oven at 70-150°C under normal pressure to obtain a dry gel;

[0041] (5) Calcining the xerogel obtained in step (4) at 600°C for 16 hours in an air atmosphere to obtain Nd 1.83 Ce 0.17 CuO 4-δ Superconductin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com