Preparation method of grapheme/hydroxyapatite composite material

A technology of hydroxyapatite and composite materials, which is applied in the application field of nano-composite materials and biological materials, can solve the problems of increased preparation cost, physical health toxicity, long reaction time, etc., achieves excellent biocompatibility, and reduces environmental pollution. , to avoid the effect of toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of graphene / hydroxyapatite composite material, concrete steps are as follows:

[0025] 1) Mix graphene oxide with a concentration of 0.5 mg / ml and a calcium nitrate solution with a calcium ion concentration of 1.0 mol / L to obtain a mixed solution 1, and then mix phosphoric acid with a calcium / phosphorus molar ratio of 1.67:1. The disodium hydrogen phosphate dodecahydrate solution with a root ion concentration of 0.67mol / L was added to the mixed solution 1 under the action of magnetic stirring and mixed evenly, and the pH was adjusted to 8 with a pH regulator—urea, to obtain the mixed solution 2 ;

[0026] 2) Transfer the mixed solution 2 into a reaction kettle, heat it at 180°C for 2 hours for hydrothermal treatment, then cool to room temperature, centrifuge, wash and freeze-dry to obtain a graphene / hydroxyapatite composite material.

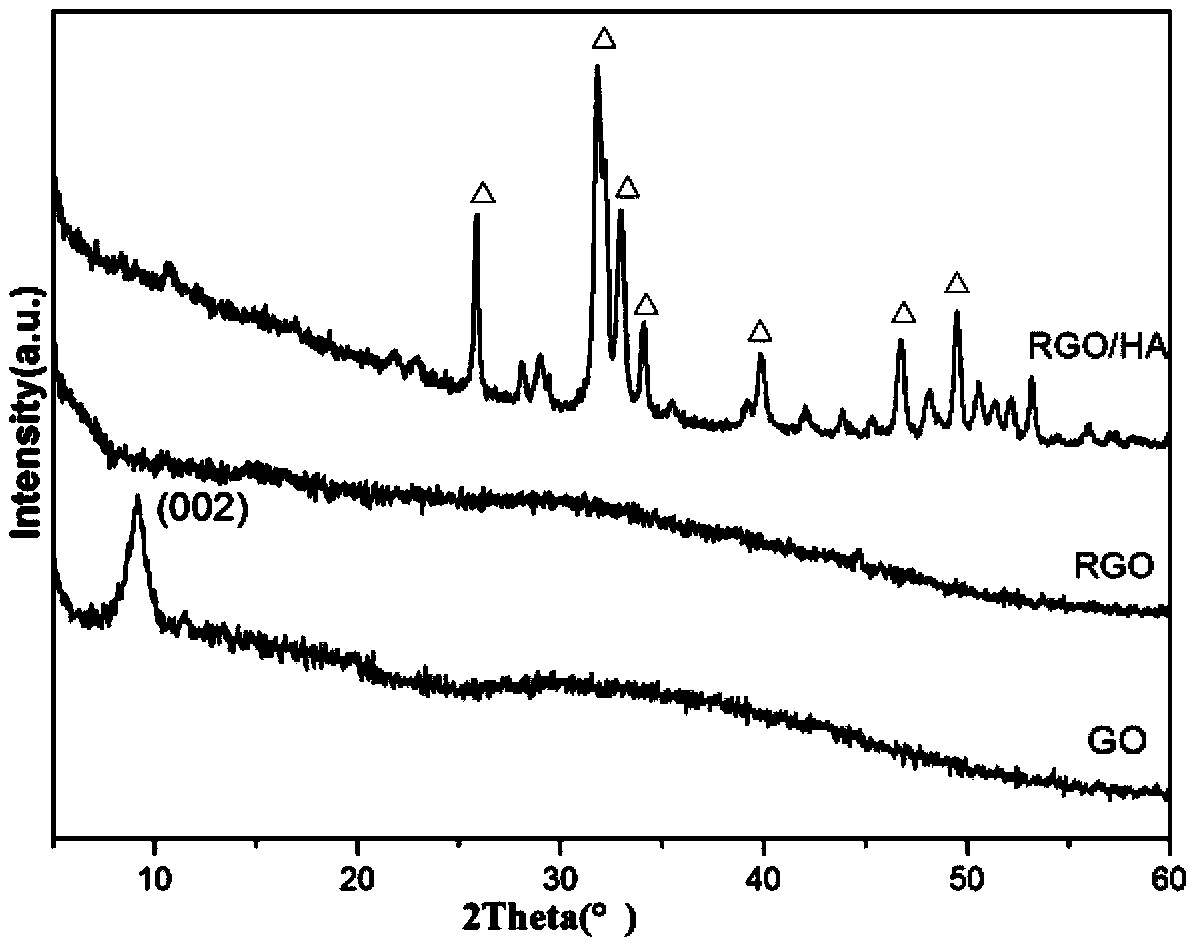

[0027] figure 1 The X-ray diffraction patterns of graphene oxide (Graphene Oxide, GO), graphene (Reduced-...

Embodiment 2

[0031] This example is basically the same as Example 1, the difference is:

[0032] The suspension with calcium ion concentration of 0.1mol / L is calcium hydroxide suspension, the phosphate solution is dipotassium hydrogen phosphate, and the pH regulator is sodium hydroxide.

Embodiment 3

[0034] This example is basically the same as Example 1, the difference is:

[0035] The suspension with a calcium ion concentration of 0.25 mol / L is calcium carbonate suspension, the phosphate solution is potassium dihydrogen phosphate, and the pH regulator is potassium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com