Corrugated paper board bonding device

A bonding device and technology for corrugated cardboard, applied in the direction of mechanical processing/deformation, etc., can solve the problems of decreased yield rate, increased moisture content of cardboard, different corrugation height of corrugated paper, etc., and achieves the effect of simple structure and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

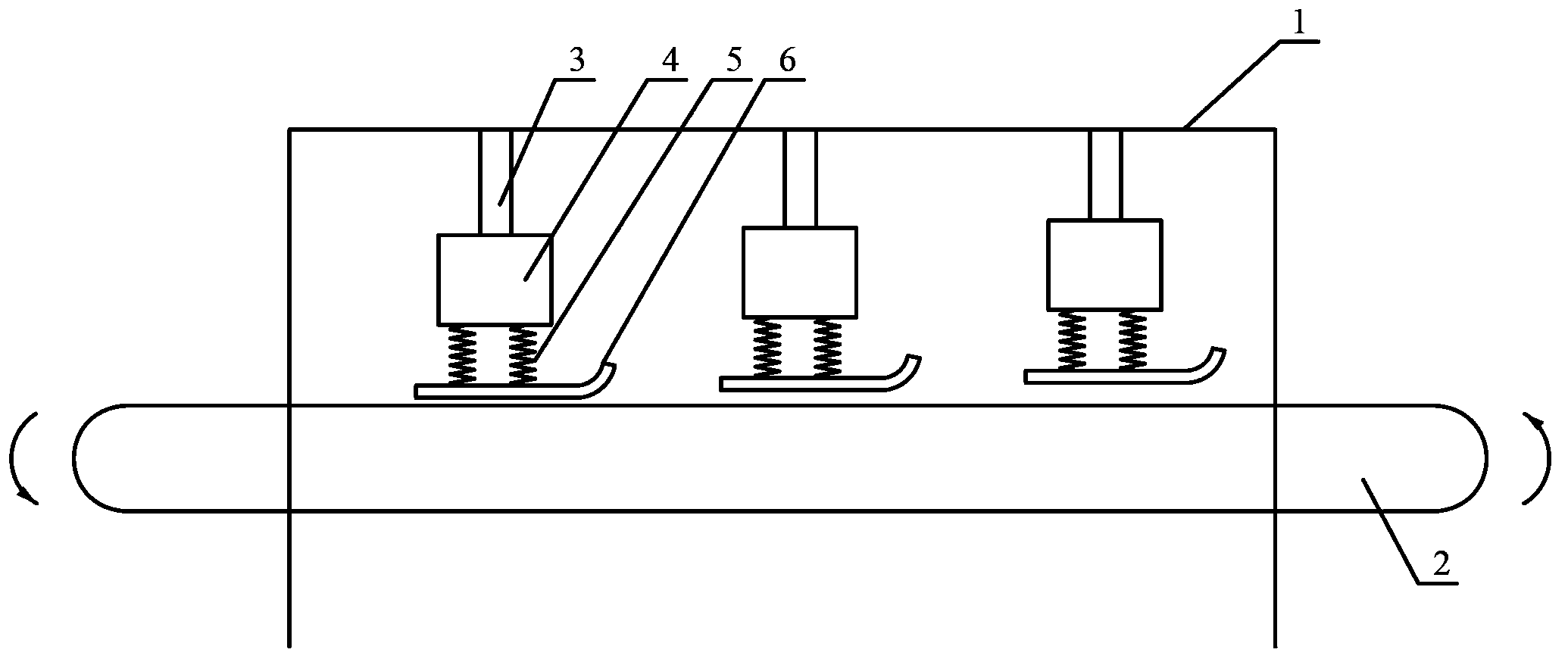

[0014] Such as figure 1 As shown, the present invention includes a support 1, several compound devices fixed on the support 1 arranged in sequence and a conveyor belt 2 below the compound device, and the compound device includes an adjustment rod fixed on the support 1 3. The vibrating device 4 fixedly installed under the adjusting rod 3 and the pressure plate 6 connected with the vibrating device 4 through the spring 5 .

[0015] Along the moving direction of the conveyor belt 2, the distance between the pressing plates 6 of several compound devices and the upper surface of the conveyor belt 2 gradually decreases.

[0016] The pressing plate 6 is rectangular, and one end facing the traveling direction of the conveyor belt 2 is raised.

[0017] The vibration device 4 is a vibration motor.

[0018] An embodiment of the present invention has been described in detail above, but the content described is only a preferred embodiment of the present invention, and cannot be consider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com