Method and device for repairing damaged conveying belt

A conveyor belt, damaged technology, applied in the field of conveyor belt repair, to achieve the effect of high efficiency, wide application range and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

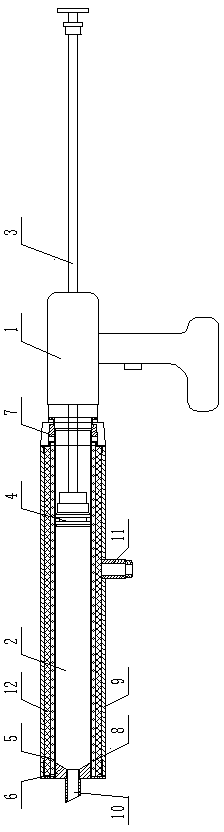

Image

Examples

Embodiment Construction

[0030] A method for repairing damaged conveyor belts, characterized in that: follow the steps below:

[0031] The first step is to take an appropriate amount of meltable elastomer and put it into the rubber tube, and heat the meltable elastomer in the rubber tube with electricity. The heating temperature is 120°C-230°C. into a molten elastomer glue;

[0032] The second step is to polish the surface of the conveyor belt to be repaired to expose a new surface;

[0033] The third step is to open the valve on the rubber cartridge, and the molten elastomer glue will flow out automatically or install the glue cartridge on the glue gun and punch it out to the new surface of the conveyor belt to be repaired;

[0034] The fourth step, the molten elastomer glue is naturally cooled and condensed, and the repair is completed.

[0035] After the second step is completed, apply the primer treatment liquid on the new surface of the conveyor belt to be repaired, and keep it for 1-10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com