Technique for casting gray cast iron thin-wall pipe fitting evanescent die

A technology of lost foam casting and gray cast iron, which is applied in the manufacture of tools, casting molding equipment, casting molds, etc. It can solve the problems of difficult core making, waste of EPS bead raw materials, irregular distribution, etc., and achieve saving of EPS bead raw materials , Simplified molding process, uniform strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

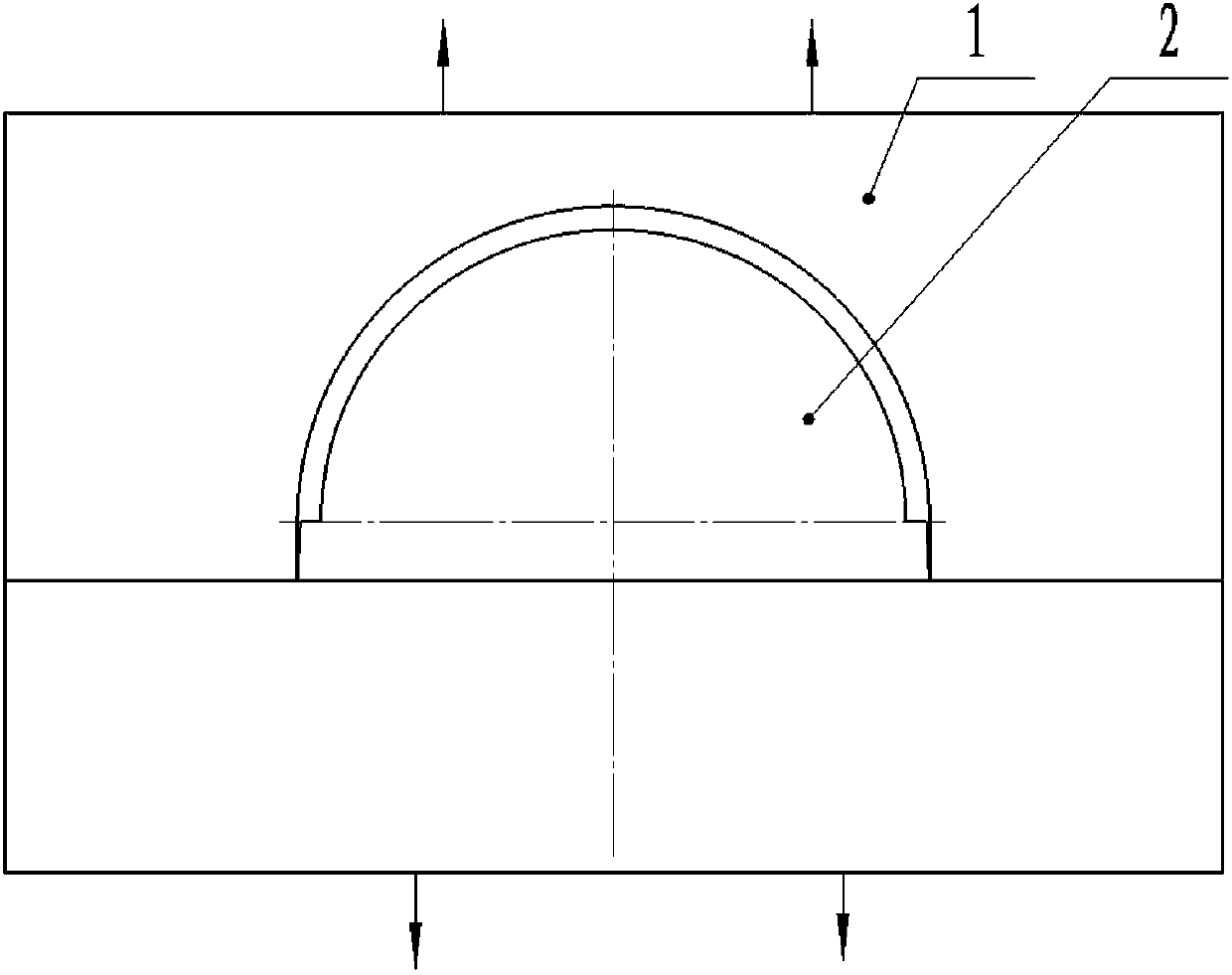

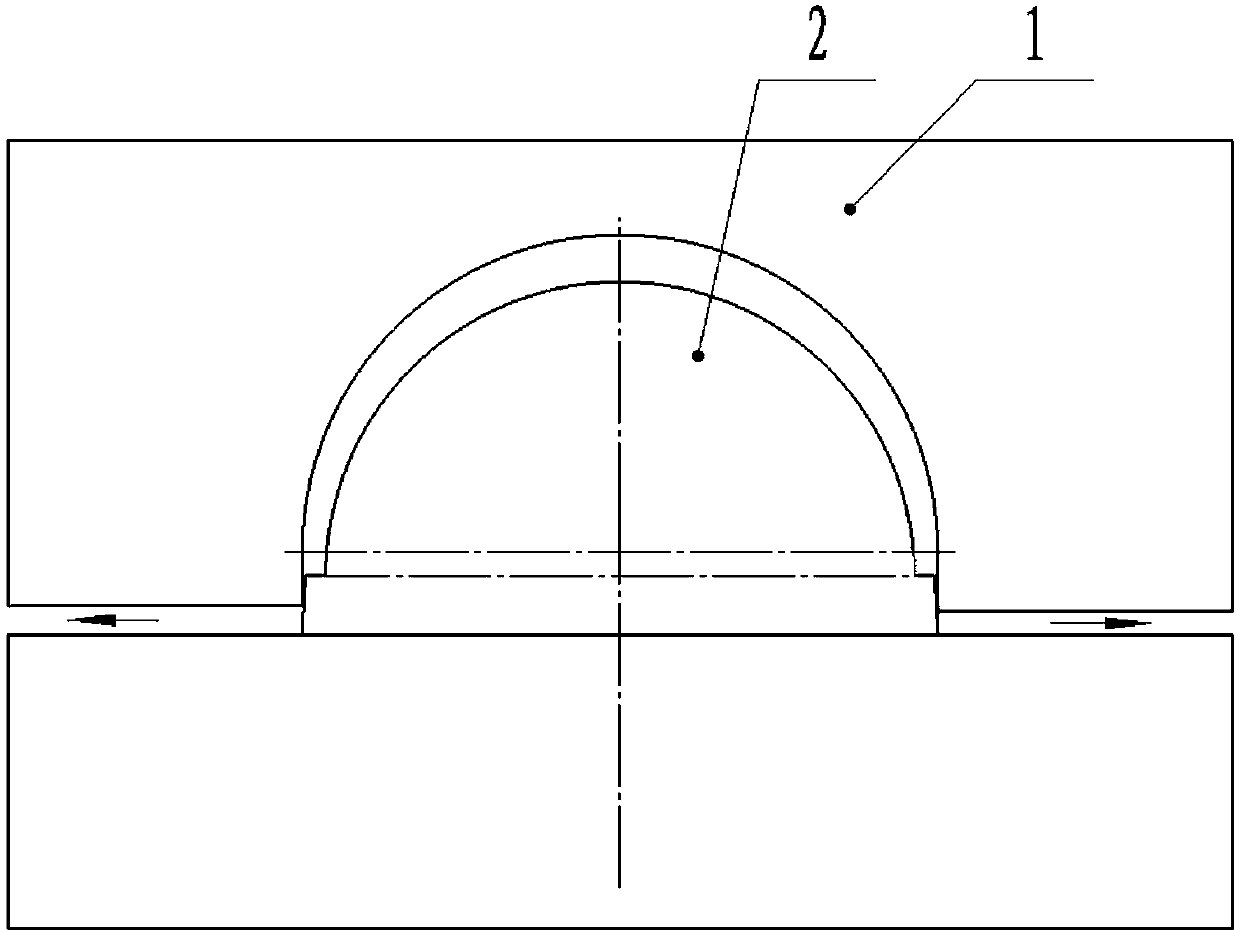

[0014] The lost foam casting process of gray cast iron thin-walled pipe fittings includes: bead pre-foaming, mold making, white mold drying and bonding, coating, drying, boxing, negative pressure casting, box grinding;

[0015] A. Bead pre-foaming

[0016] First, select GP-45 standard polystyrene beads and add them to the foaming machine for pre-foaming. The steam pressure is 0.1-0.15kg / cm 2 , the temperature of the foaming barrel is 98-100oC, and the air pressure is 0.05-0.1kg / cm 2 , The feeding amount at one time is 0.7~1kg. After the beads are foamed and unloaded, they are dried in a fluidized bed with hot air at a drying temperature of 20~25oC. After the beads of gray cast iron thin-walled pipe fittings are pre-foamed, the average diameter of the beads is ¢1mm, and the density is controlled at 26-28 grams / cm 3 , so that the white mold made has certain strength and rigidity;

[0017] B. Molding

[0018] Operate the forming machine to close the mold, fill the foamed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com