Boiler maintenance gray supporting platform and building method thereof

A technology for supporting platforms and boilers, which is used in construction, building structure, housing structure support, etc., can solve the problems of high-altitude operation, such as high risk, time-consuming, large gaps, etc. The effect of the overall structure is flat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

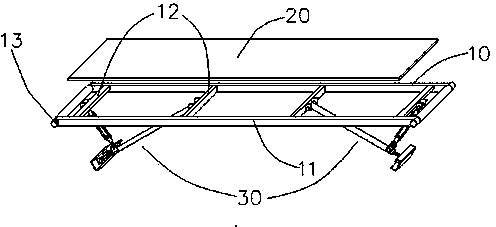

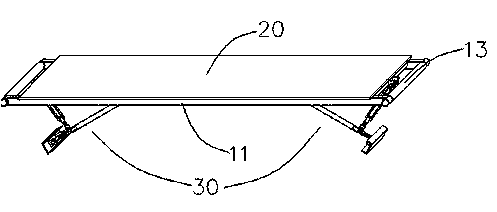

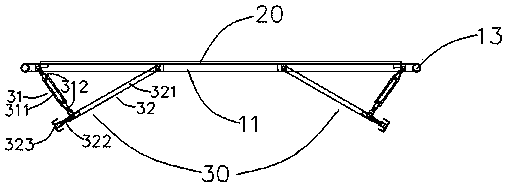

[0051] This embodiment provides a support platform for boiler overhaul ash opening, such as Figure 1 to Figure 3 As shown, it is composed of multiple sets of unit load-bearing components arranged and connected in sequence. Each set of unit load-bearing assembly is made up of unit load-bearing bracket 10, unit support plate 20 and two unit triangular support anti-skid devices 30, and described unit support plate 20 is laid on the surface of described unit load-bearing support 10, and described two unit triangular The support anti-skid device 30 is respectively arranged on the two ends of the lower part of the unit load-bearing bracket 10; the two ends of the unit load-bearing bracket 10 and the bottom end of the unit triangular support anti-skid device 30 are used as legs, and are all used to abut against the parts that need to be overhauled. On the slope surface 1 of the ash mouth of the water wall of the boiler.

[0052] Each of the unit load-bearing brackets 10 includes tw...

Embodiment 2

[0060] This embodiment provides another support platform for the boiler overhaul ash opening, which is similar to the first embodiment, the only difference is that the boiler overhaul ash opening support platform in this embodiment also includes a multi-plate tie rod connection fastening anti-skid device to prevent it from turning over .

[0061] In Embodiment 1, a multi-plate tie rod is respectively arranged in the gaps at both ends of the multiple sets of unit load-bearing components to connect to the pressure plate 51 of the anti-slip fastening device, and each of the multi-plate tie rods is connected to each of the pressure plates 51 of the anti-slip fastening device. At a distance, connect one end of a multi-plate tie rod to connect the anti-slip fastening rod 52, and the other end of the multi-plate tie rod to connect the anti-skid fastening rod 52 is movably connected to the same bottom fixed fastening rod 53, and the bottom fixed fastening rod The two ends of 53 are re...

Embodiment 3

[0065] This embodiment provides a method for building the support platform for the ash opening of the boiler overhaul described in the second embodiment.

[0066] This embodiment includes the following steps:

[0067] Such as Figure 8 As shown, one or more unit load-bearing components are directly placed on the ash opening in the furnace through the manhole door 60 provided on the 6-12 meter high boiler inspection staircase, and then laid and installed, and another to two people pass through the After the manhole door 60 enters, step on the laid unit load-bearing assembly, and lay the work according to the needs of the inner length of the boiler;

[0068] One to two people outside the boiler inspection stair part pass a plurality of unit load-bearing assemblies to the personnel laying inside through the boiler ash manhole door 60, and the inside laying personnel connect and lay the multiple unit load-bearing assemblies in sequence.

[0069] The advantages of this method are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com