High-safety undercutting anchor bolt and connecting structure of building appurtenance

A technology of appendages and riveting bolts, which is applied to building structures, building components, buildings, etc., can solve problems such as unsoldering safety hazards, difficult work, and unreasonable coordination, so as to improve seismic performance, save installation labor, and reduce The effect of installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

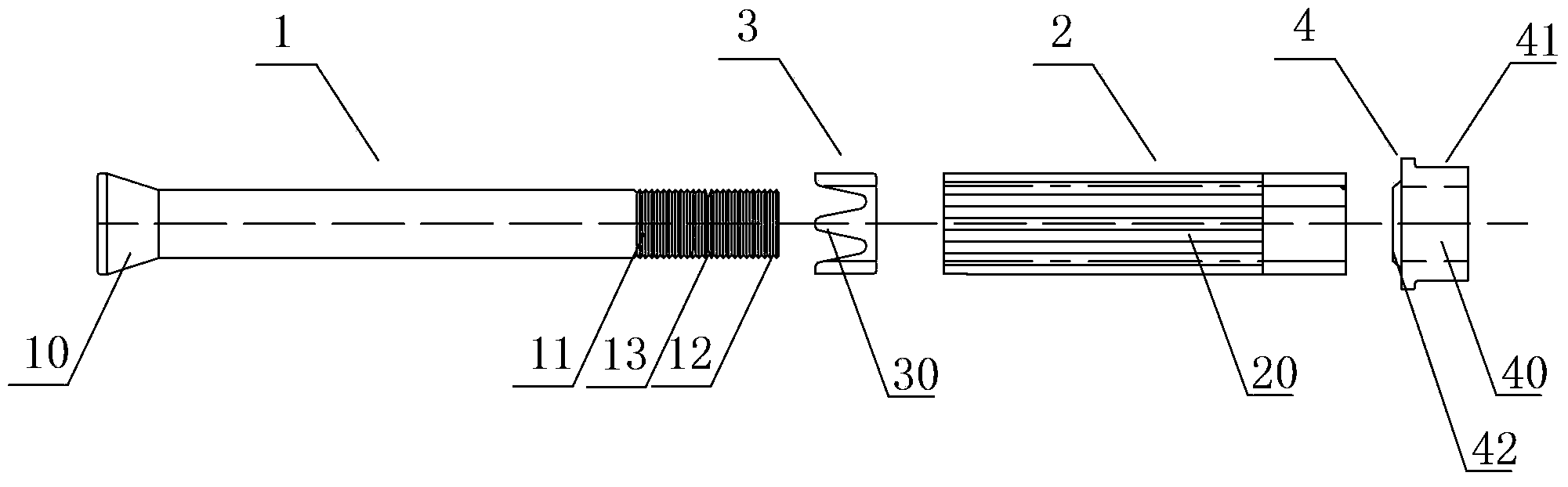

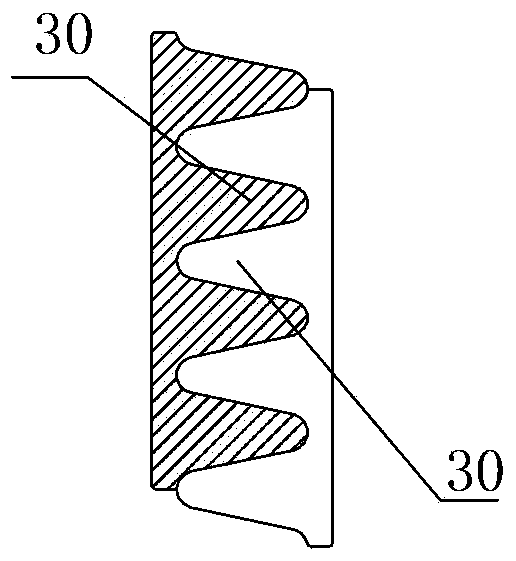

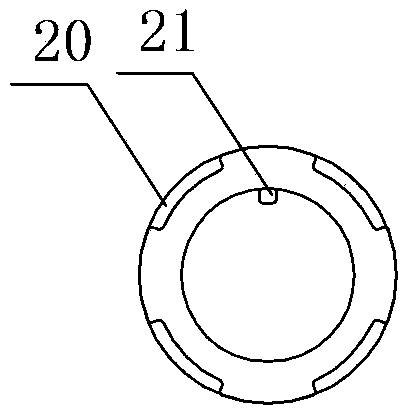

[0037] Refer to attached picture. A bottom-cut rivet provided by the present invention includes a metal rivet 1, a sleeve 2, and an expansion part 3. The head of the metal rivet 1 is an expansion head 10, and the expansion head 10 cooperates with the expansion part 3 to expand it. into the bottom undercut 102 of the connection hole 101 of the substrate 100 .

[0038] The metal rivet rod 1 includes an anti-loosening riveting section 11 corresponding to the outside of the connecting hole 101, and the surface of the anti-loosening and riveting section is provided with anti-stripping lines, such as concave lines, embossed lines, rings, annular grooves, etc. Make the surface of the anti-loosening riveting section 11 uneven. In addition to the anti-loosening and riveting section 11, there is a connection section 12 for connecting with the tool. There is a breaking position 13 between the connection section 12 and the anti-loosening and riveting section 11. The connection portion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com