Transmission device of washer driving mechanism, washer driving mechanism and washer

A technology of driving mechanism and transmission device, which is applied in the field of washing machines, can solve the problems of high installation accuracy, low transmission efficiency, and large transmission noise, and achieve the effects of avoiding burning accidents, improving transmission efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

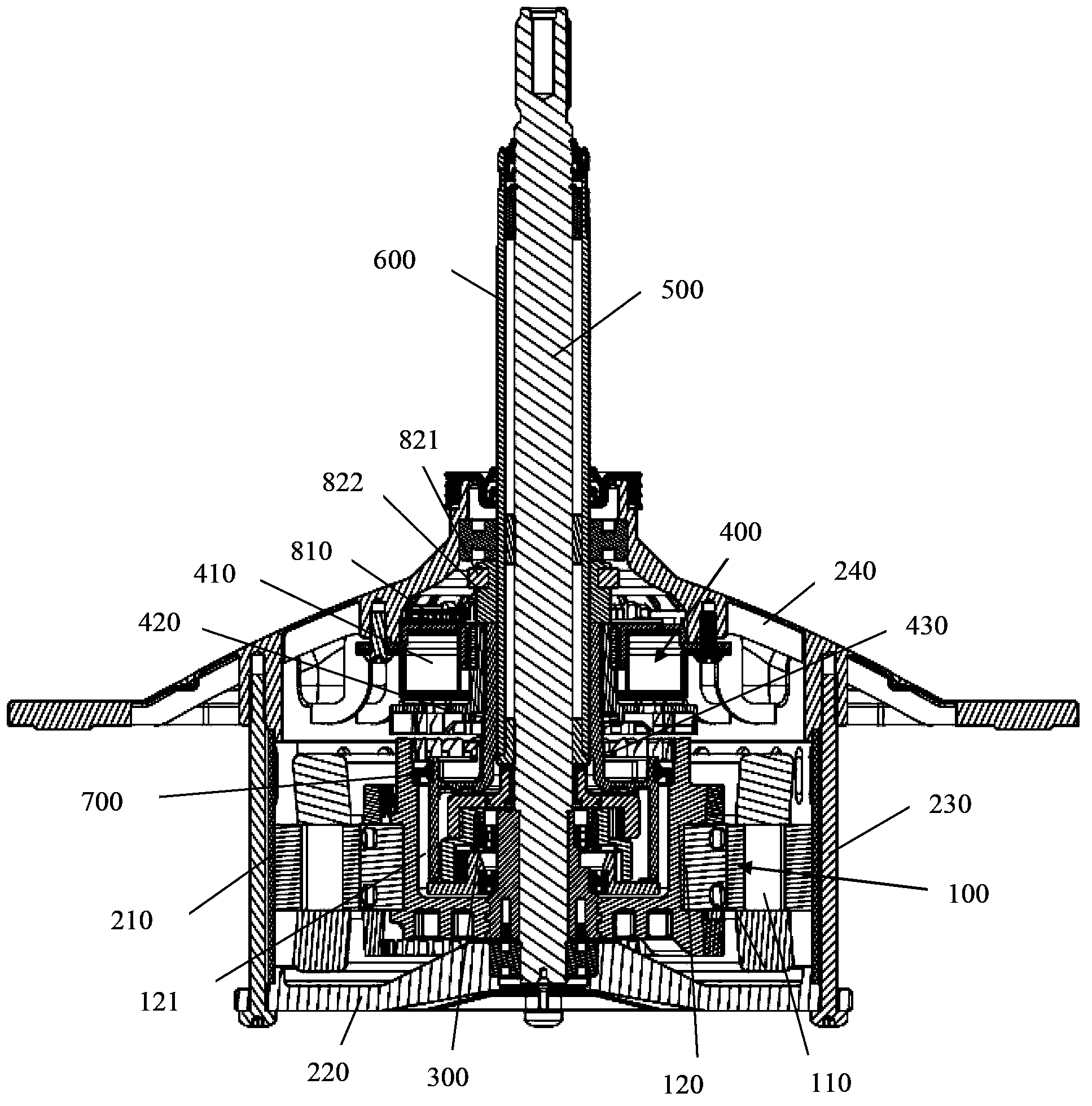

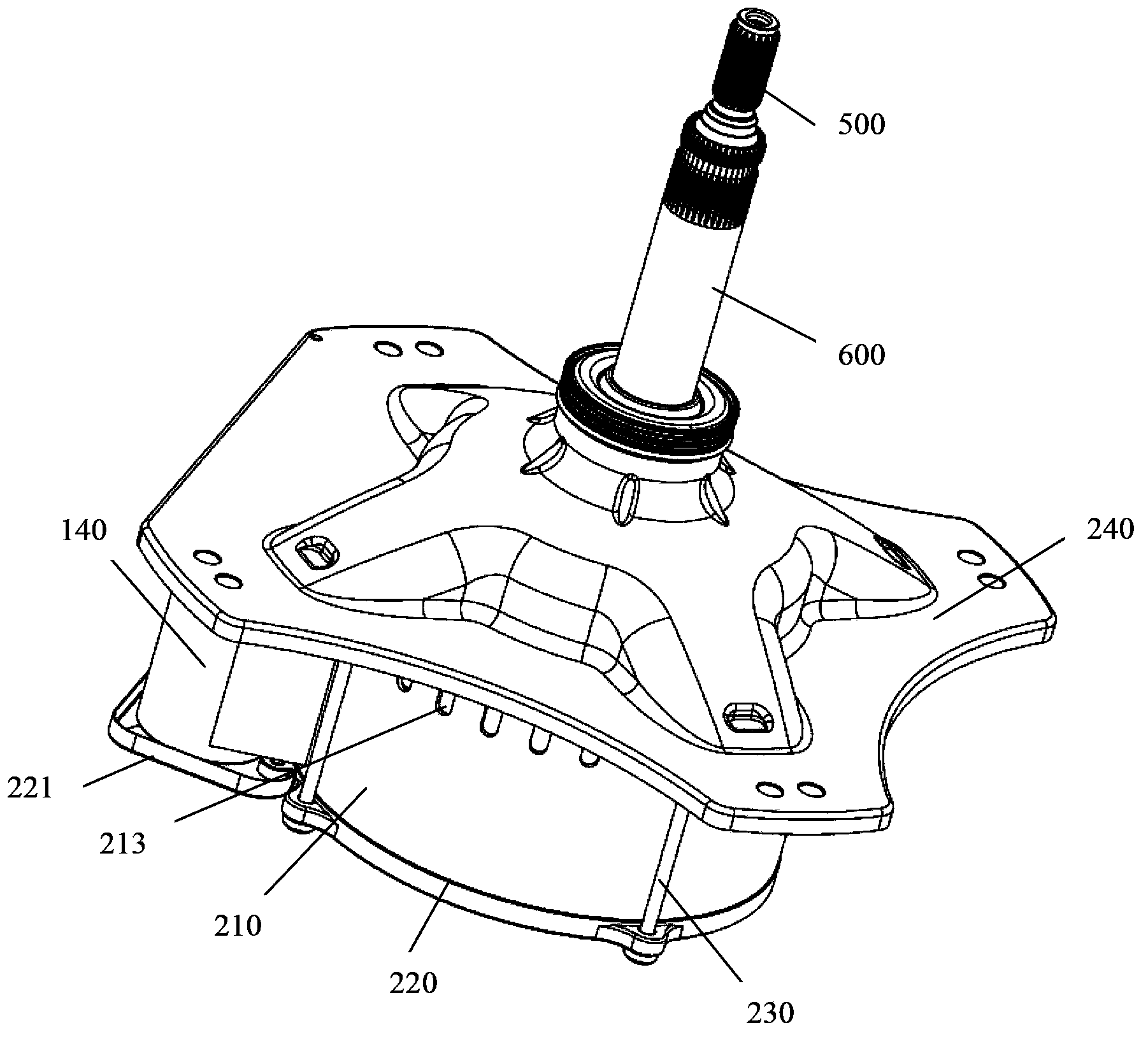

[0051] The embodiment of the invention discloses a transmission device of a washing machine driving mechanism. The washing machine driving mechanism includes a shaftless rotating body for providing rotational kinetic energy, a transmission device, a washing shaft and a dehydration shaft sleeve. The dehydration shaft sleeve is sleeved on the outside of the washing shaft and rotates with it connections; where the transmission includes:

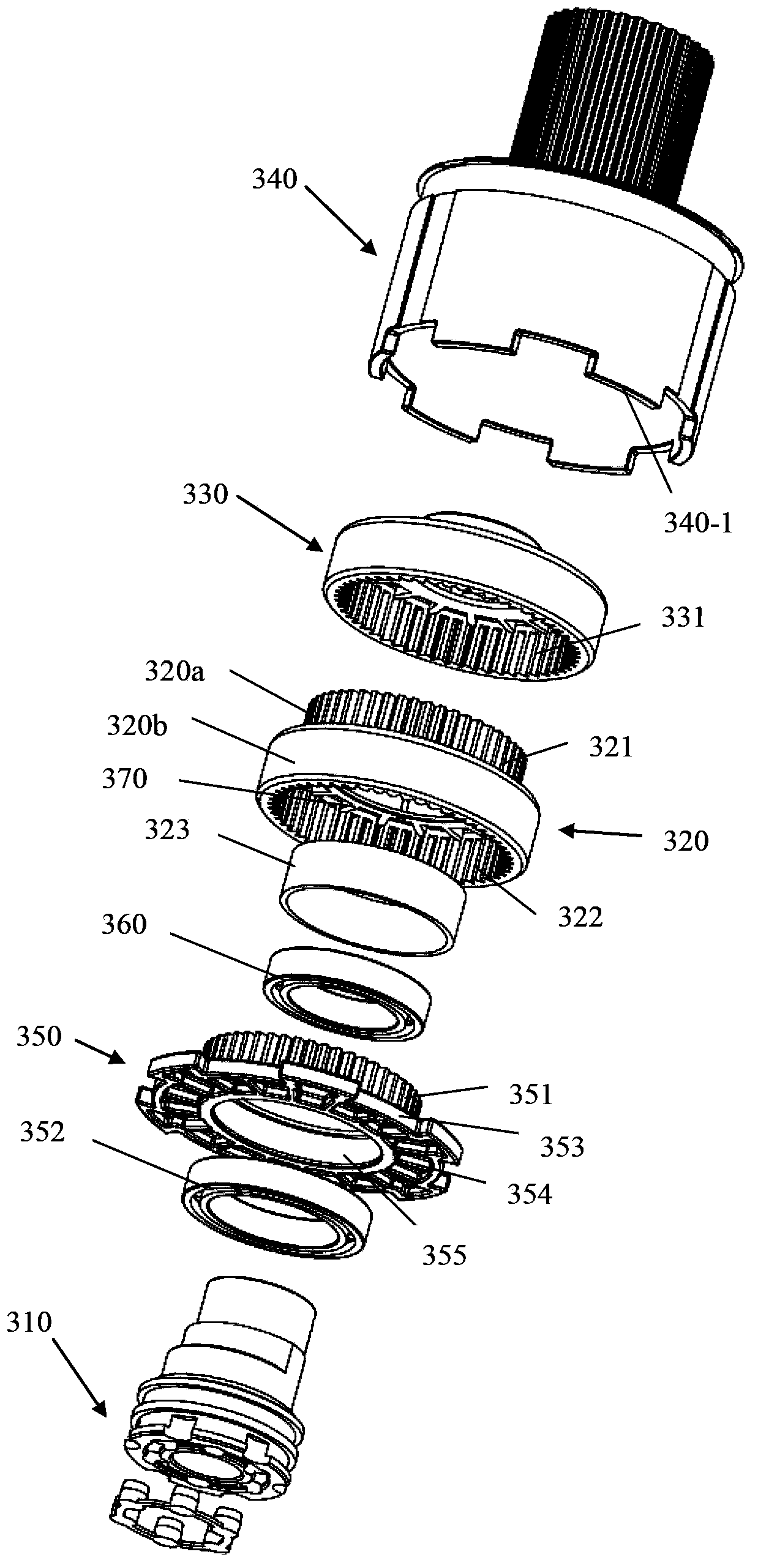

[0052] The eccentric sleeve that is fixedly connected to the rotating body and rotates around the axis of the rotating body; the spur gear that is fitted outside the eccentric sleeve and connected in rotation with it is used to revolve around the axis of the rotating body with the rotation of the eccentric sleeve. The different axial positions of the spur gear The first spur gear segment and the second spur gear segment are respectively arranged on the top; the first output gear fixedly connected to the washing shaft, the first output gear meshes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com