Bacterial strain capable of producing alkali protease and industrialized liquid fermentation method of bacterial strain

A liquid fermentation and protease technology, applied in the field of bioengineering, can solve the problem of high production cost, achieve the effects of simple operation, mild culture conditions and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Screening of starting bacterial strain

[0038] (1) Take 2g soil sample from the saline-alkali land rich in organic matter, add it to a small triangular flask containing 50mL of cooled sterile water, shake the table at 200r / min, shake for 20min, then place it in a water bath at 80°C for 10min, continuously Shake the Erlenmeyer flask to mix the soil sample, let it stand for 5 minutes, absorb 100 μL of the supernatant, and gradually dilute to 10 -1 ~10 -9 Concentration, select 10 -3 , 10 -4 , 10 -5 , 10 -6 Concentration coated beef extract peptone plate, cultivated at 37°C for 24h, and continued to cultivate at 30°C for 24h.

[0039] (2) According to the characteristics of the shape, size, surface structure, edge structure, texture, gloss, transparency, color and soluble pigments of the microbial colony, use the inoculation loop to pick out the isolated single colony and move it to the screening culture Base plate, and numbered, 34 ℃ for 48h.

[0040]...

Embodiment 2

[0046] The mutagenesis screening of embodiment 2 bacterial strains

[0047] (1) Ultraviolet mutagenesis

[0048] Aspirate the 10-12h bacterial solution of the originating strain and pour it into a flat dish, and the amount of bacterial solution in each flat dish is 10mL. Place the plate containing the bacterial solution on the magnetic stirrer under the ultraviolet lamp in the mutagenesis box, and the vertical distance between the plate and the ultraviolet lamp is 30 cm. Turn on the UV lamp and preheat for 30 minutes to stabilize the light wave. Adjust the rotation speed of the stirring bar. After the rotation speed is stable, open the lid of the plate for irradiation, and start timing. The irradiation time of the plate is 1, 2, 3, 4, 5, 6, 7, 8, 9, and 10 minutes respectively. Take out 0.1ml of bacterial suspension from each plate and make appropriate dilutions to obtain bacterial suspensions with different dilutions. Draw 0.3ml of the diluted bacterial suspension to coat ...

Embodiment 3

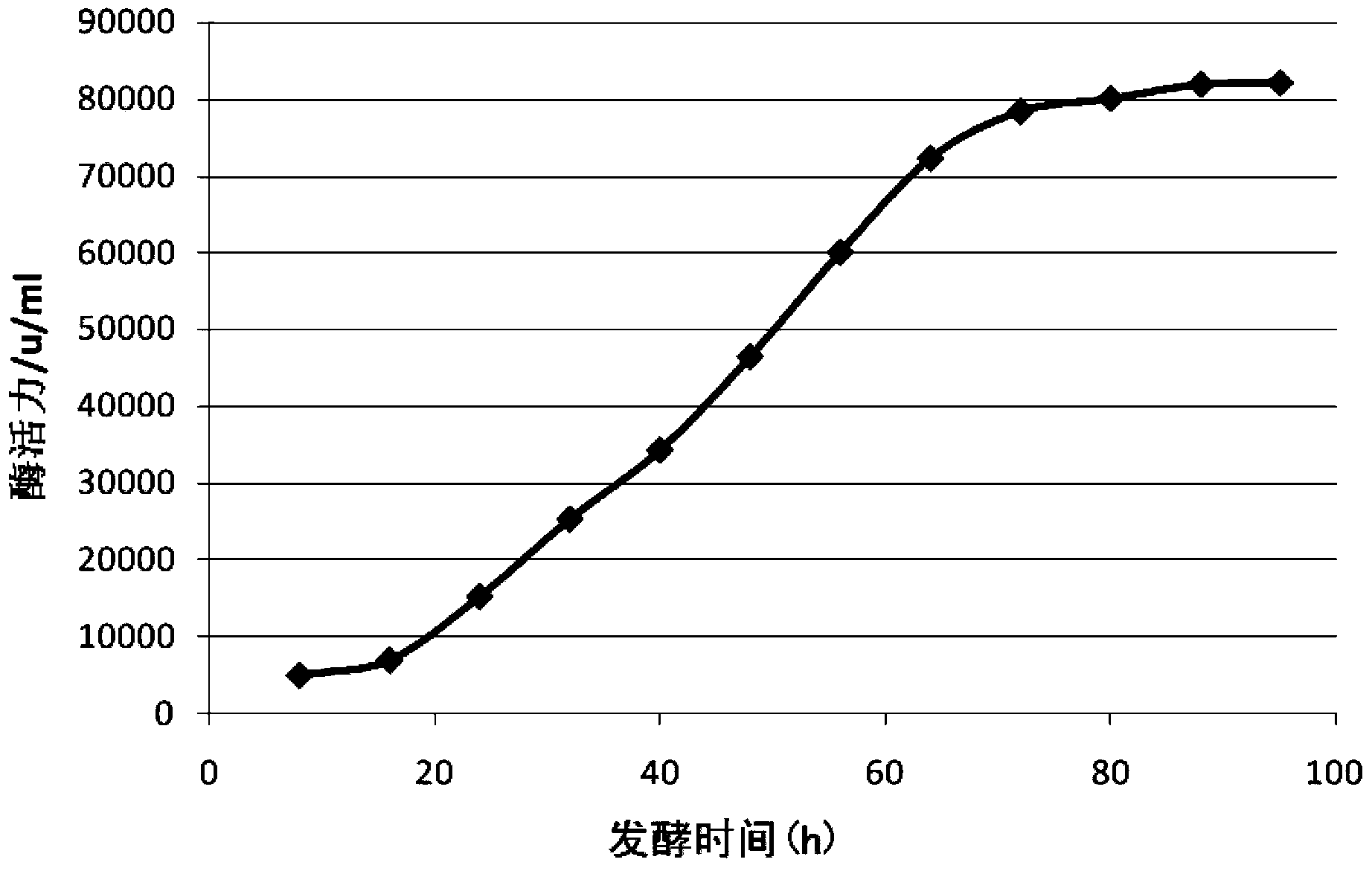

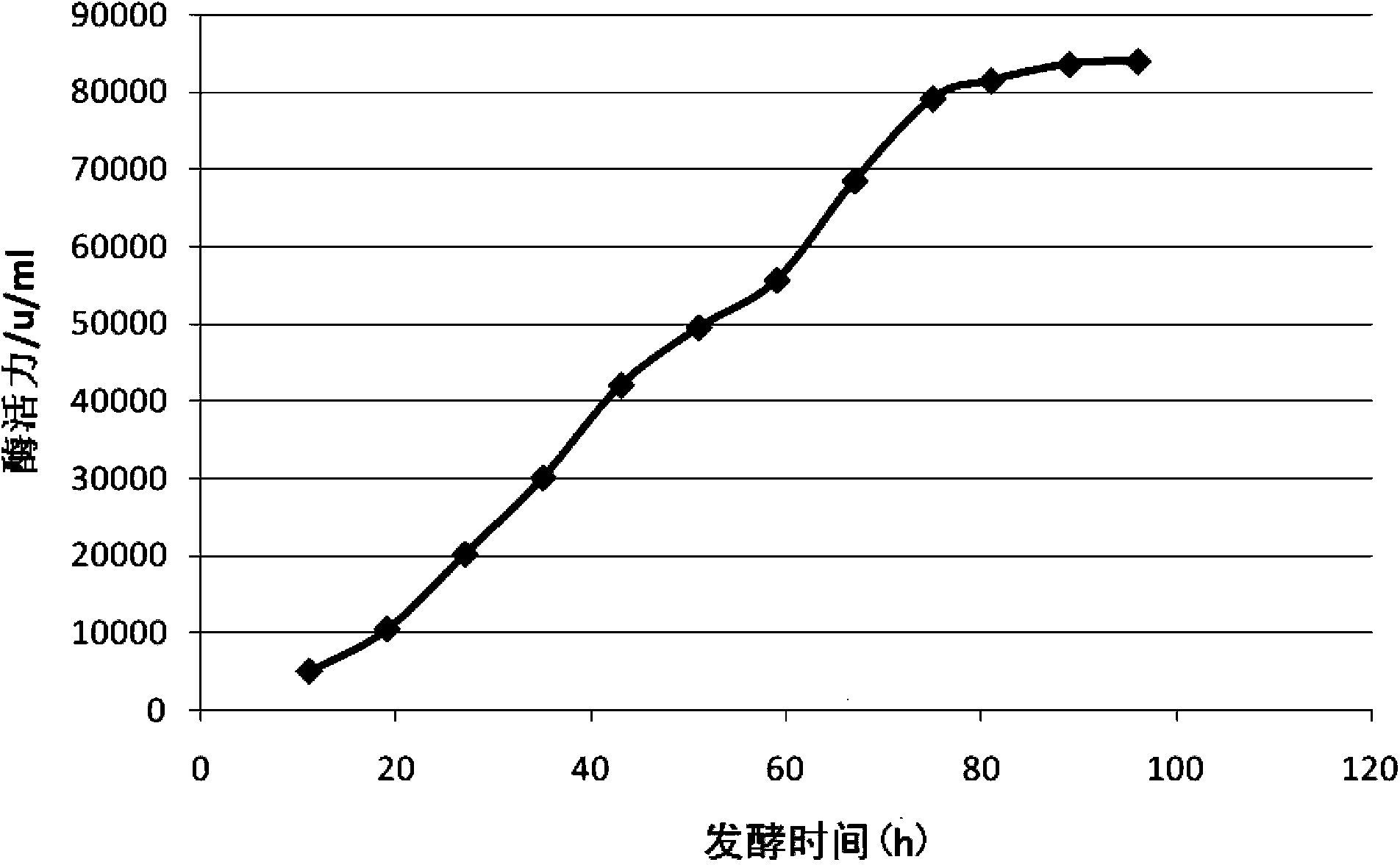

[0063] A kind of liquid submerged aerated fermentation method using Ap180 alkalophilic bacillus strain as production strain, comprises the steps:

[0064] (1) First-level seed culture: Inoculate the slant strain of Bacillus alkalophilus Ap180 into a 500-ml shaker flask, with a medium volume of 100 ml, a rotary shaker at 180 rpm, a culture temperature of 34°C, and a culture time of 11 hours;

[0065] (2) Secondary seed cultivation: Put the first-grade seeds into 500 ml second-grade seed shake flasks according to the inoculation amount of 10%, and the cultivation conditions are the same as the first-grade seeds;

[0066] (3) Tertiary seed cultivation: Inoculate the secondary seeds with 10% inoculum amount into a 5000 ml tertiary seed shaker flask, with a medium capacity of 1000 ml, a rotary shaker at 100 rpm, and a culture temperature of 34°C. time 11h;

[0067] (4) First-level seed tank cultivation: Put the third-level seeds into the first-level seed tank with a total volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com