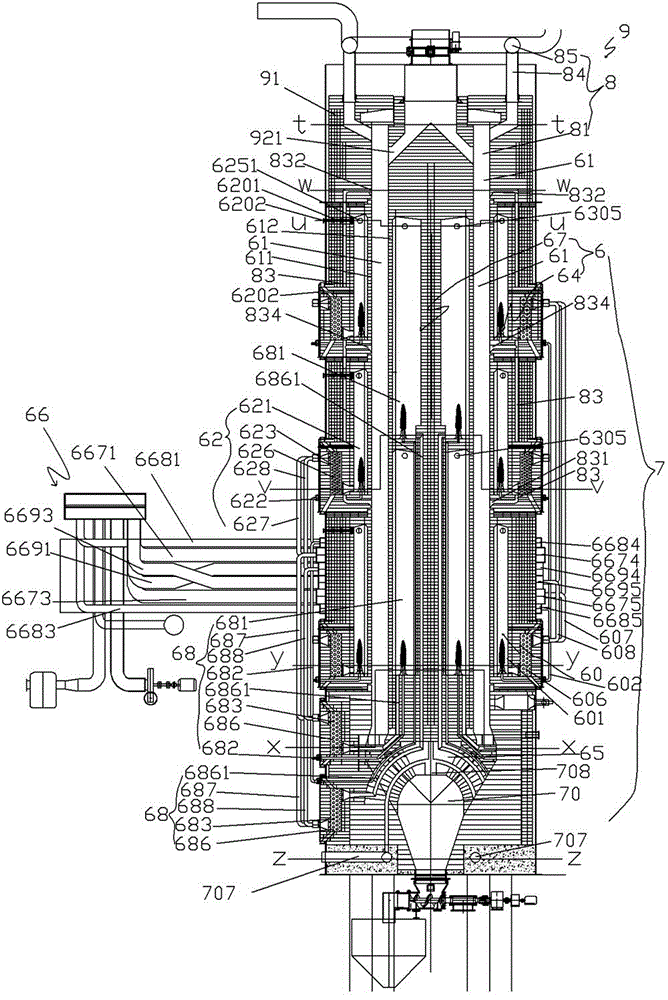

Continuous external heated water gas gasification furnace

A water gas and external heat technology, applied in the field of coal gas production, can solve the problems of complex process pipeline, low production efficiency, low production intensity, etc., and achieve the effects of high hydrogen content, improved production efficiency and reasonable ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

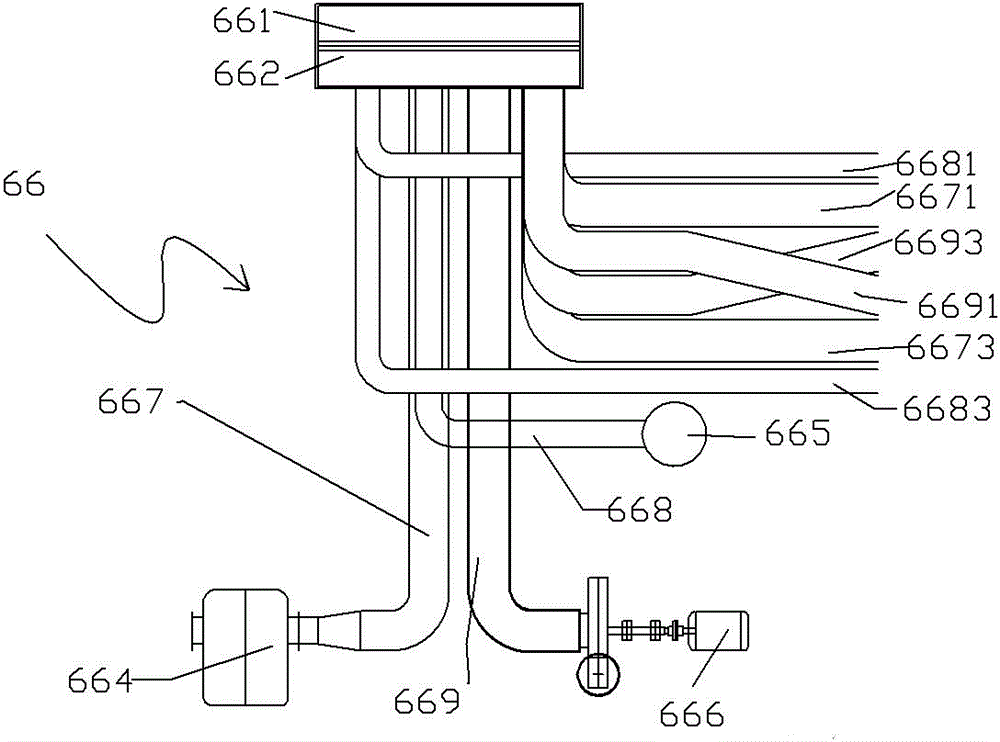

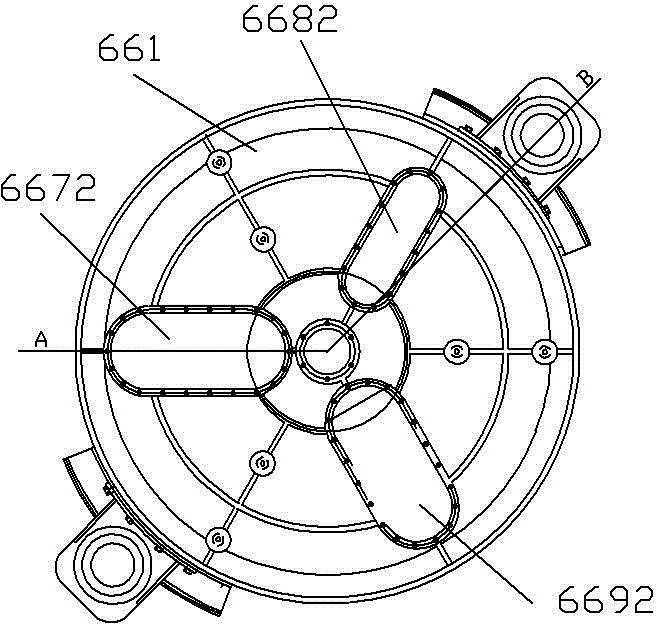

[0045] The specific embodiments of the continuous external heating water gasification comprehensive process of the present invention are mainly introduced in detail below.

[0046] Part 1 Particle Size Control of Low Rank Coal

[0047] Smokeless, anhydrous, low ash and high activity anthracite with particle size of 10~50mm obtained by pyrolysis of low-rank coal (lignite) is used as raw material for water gasification. Sufficiently, but this does not constitute a limitation to the low-rank coal (lignite) required by the present invention, and the present invention is also applicable to the water gas reaction of anthracite or coke.

[0048] The second part smokeless charcoal preheating

[0049] Such as Figure 19 , Figure 16 As shown: the preheating bin 1 includes a casing 11, a hot gas heat exchanger 13, and a lower bin 14; a bin 111 for preheating smokeless charcoal is formed in the casing 11, and the top of the bin 111 is relatively closed. Feeding port 112, is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com