Dye for supercritical carbon dioxide dying and preparation and application of dye

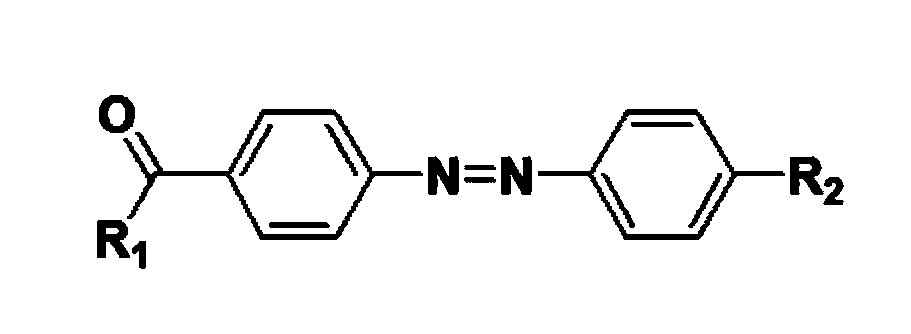

A supercritical dye technology, applied in dyeing, azo dyes, organic dyes, etc., can solve the problem of energy consumption, achieve good solubility and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

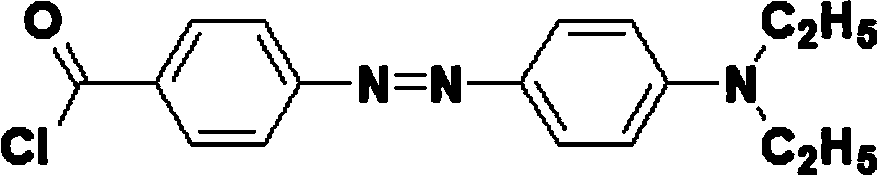

Examples

Embodiment 1

[0029] Dry the dye Ⅰ, put it into the dissolving tank according to the amount of 1% owf (owf refers to the weight ratio of dye to cotton fabric) after crushing, then wind the cotton fabric on the stainless steel shaft, and fix it together under the high pressure of supercritical carbon dioxide in the stain tank. Dyeing is carried out under the condition that the pressure reaches 15-20Mpa and the temperature reaches 60°C. The dyeing time is 1h, then stop the equipment, and recover carbon dioxide after the temperature and pressure decrease. Take out the dyed cotton fabric, and test its color fastness and fixation rate. See Table 1 and Table 2 for specific data.

Embodiment 2

[0031] Dye II was dyed according to the conditions of Example 1. The dyed cotton fabrics were tested for color fastness and fixation rate. See Table 1 and Table 2 for specific data.

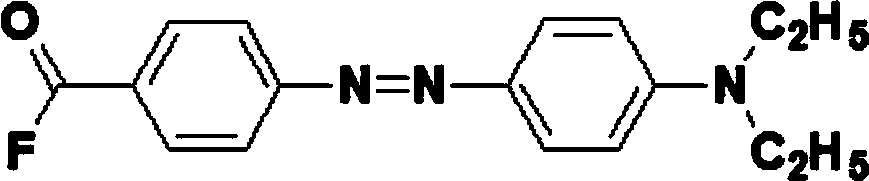

Embodiment 3

[0033] Dry the dye Ⅰ well, put it into the dissolving tank according to the amount of 1% owf after crushing, then wind the cotton fabric on the stainless steel shaft, and fix it together in the high-pressure dyeing tank of supercritical carbon dioxide. Dyeing is carried out under the condition that the pressure reaches 15-20Mpa and the temperature reaches 80°C. The dyeing time is 1h, then stop the equipment, and recover carbon dioxide after the temperature and pressure decrease. Take out the dyed cotton fabric, and test its color fastness and fixation rate. See Table 1 and Table 2 for specific data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com