A kind of PBT composite material and preparation method thereof

A composite material and compound technology, which is applied in the field of PBT composite materials and its preparation, can solve the problems of poor compatibility and difficulty in guaranteeing the low temperature resistance of PBT composite materials, and achieve the effects of enhanced low temperature resistance, high production efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment PB

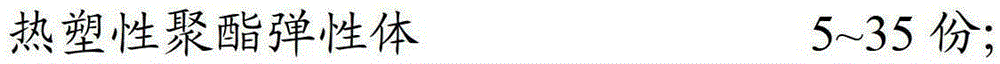

[0022] The embodiment of the present invention PBT composite material, comprises the component of following parts by weight:

[0023] 5 parts of thermoplastic polyester elastomer (TPEE7246); 5 parts of PBT110082; 5 parts of glass fiber; 3 parts of compatibilizer (SMA); 0.1 parts of KH-5600, 0.1 parts of ADR-43700; ) 0.1 parts. Among them, KH-560 is compounded with ADR-4370 to form a coupling agent, and OP1240 is compounded with MR01 to form a halogen-free flame retardant.

[0024] The preparation method of the PBT composite material of the embodiment of the present invention comprises the following steps:

[0025] a: Weigh each component according to the above parts by weight, first dry the thermoplastic polyester elastomer and compatibilizer in a vacuum oven at 45°C for 3-4 hours;

[0026] b: uniformly mixing the halogen-free flame retardant and the coupling agent in a high-speed mixer to obtain the first mixture;

[0027] c: Add the PBT resin, dispersant, thermoplastic poly...

Embodiment 2

[0030] The embodiment of the present invention PBT composite material, comprises the component of following parts by weight:

[0031] 15 parts of thermoplastic polyester elastomer (TPEE6356); 45 parts of PBT110045 parts; 10 parts of glass fiber; 4 parts of compatibilizer (SMA); 0.3 parts of KH-5600, 0.6 parts of ADR-43700; MB50-007) 0.5 parts. Among them, KH-560 is compounded with ADR-4370 to form a coupling agent, and OP1240, 300A is compounded with MR01 to form a halogen-free flame retardant.

[0032] The preparation method of the PBT composite material of the embodiment of the present invention comprises the following steps:

[0033] a: Weigh each component according to the above parts by weight, first dry the thermoplastic polyester elastomer and compatibilizer in a vacuum oven at 45°C for 3-4 hours;

[0034] b: uniformly mixing the halogen-free flame retardant and the coupling agent in a high-speed mixer to obtain the first mixture;

[0035] c: Add the PBT resin, dispe...

Embodiment 3

[0038] The embodiment of the present invention PBT composite material, comprises the component of following parts by weight:

[0039] Thermoplastic polyester elastomer (TPEE6356) 25 parts; PBT110028 parts; glass fiber 20 parts; compatibilizer (SMA) 5 parts; KH-5600.5 parts, ADR-43700.5 parts; 300A18 parts, MR012 parts; ) 1 part. Among them, KH-560 is compounded with ADR-4370 to form a coupling agent, and 300A is compounded with MR01 to form a halogen-free flame retardant.

[0040] The preparation method of the PBT composite material of the embodiment of the present invention comprises the following steps:

[0041] a: Weigh each component according to the above parts by weight, first dry the thermoplastic polyester elastomer and compatibilizer in a vacuum oven at 45°C for 3-4 hours;

[0042] b: uniformly mixing the halogen-free flame retardant and the coupling agent in a high-speed mixer to obtain the first mixture;

[0043] c: Add the PBT resin, dispersant, thermoplastic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com