Attapulgite and zinc lignosulphonate-based interpenetrating network-type water-retention and slow-release zinc fertilizer

An interpenetrating network type and calcium lignosulfonate technology is applied in the field of attapulgite and zinc lignosulfonate-based interpenetrating network type water-retaining and slow-release zinc fertilizers, which can solve the problems of not producing water-retaining and slow-release fertilizers, and achieve Great practical value and strategic significance, the effect of improving mechanical strength and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

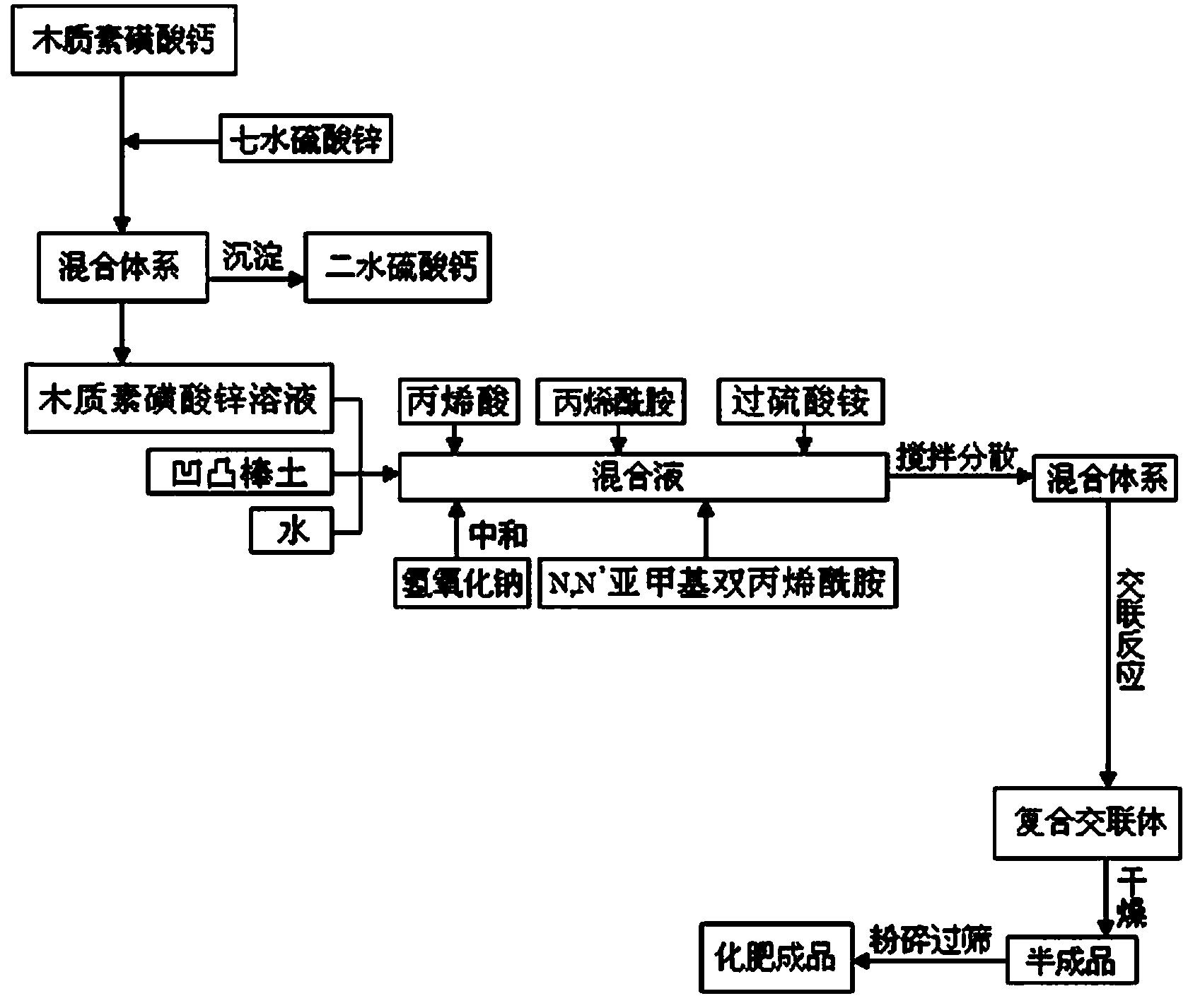

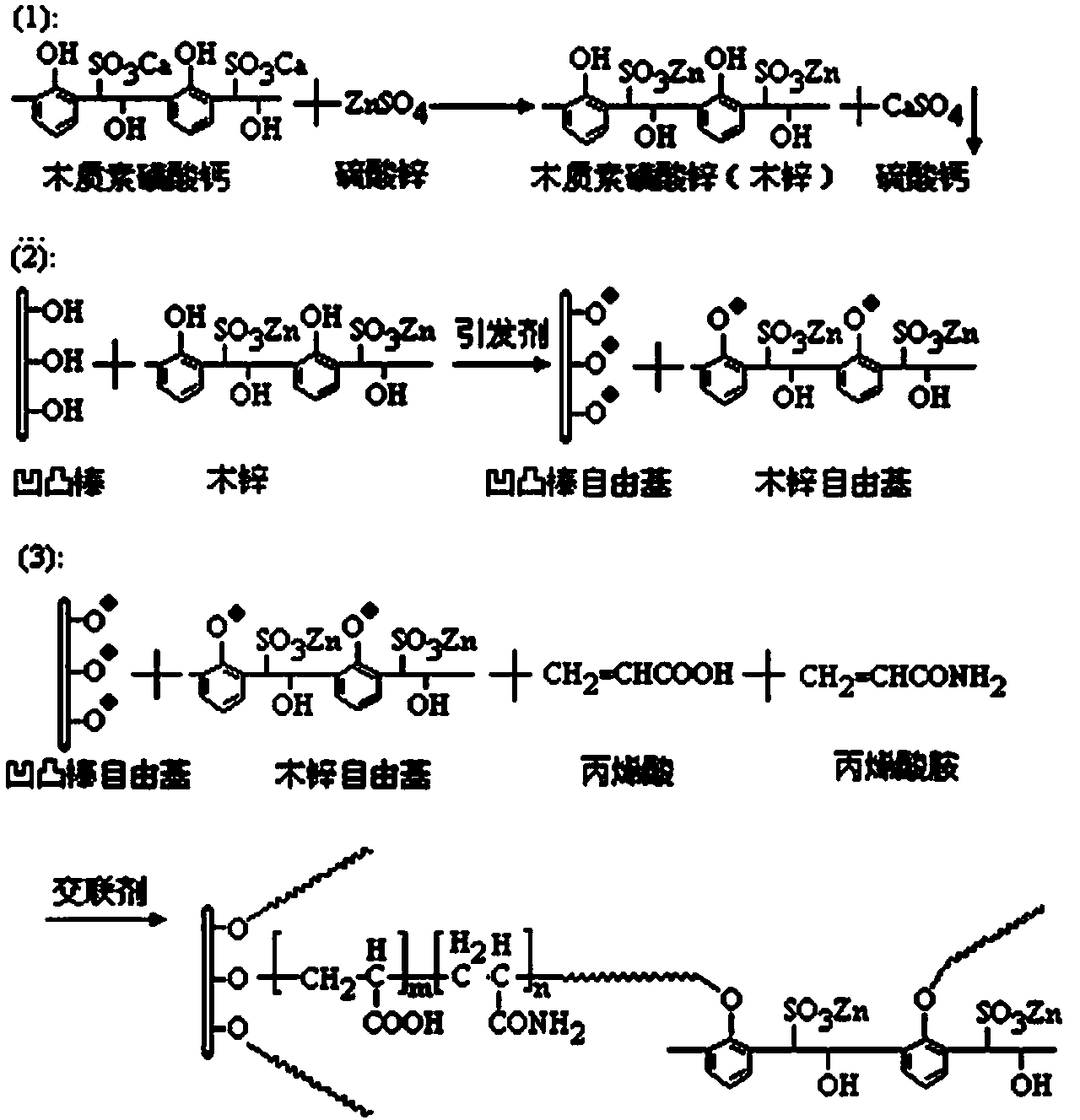

[0032] The preparation mechanism of water-retaining slow-release zinc fertilizer of the present invention is as follows: figure 2shown. First, zinc lignosulfonate (also known as wood zinc) is obtained by reacting zinc sulfate with calcium lignosulfonate. Subsequently, in the mixed system of attapulgite and zinc lignosulfonate, the hydrogen atom in the silicon hydroxyl group on the surface of the attapulgite and the hydrogen atom in the phenolic hydroxyl group of zinc lignosulfonate are captured by the initiator (ammonium persulfate) to initiate Primary free radicals, and then initiate acrylic acid (and acrylamide) to form "attapulgite-zinc lignosulfonate-acrylic acid-acrylamide" free radicals, which continue to undergo chain growth polymerization reactions with acrylic acid and acrylamide, And under the action of cross-linking agent (N,N'-methylenebisacrylamide), a three-dimensional polymer resin network structure is formed. In this network structure, since the attapulg...

Embodiment 1

[0036] According to mass percentage, take 0.5% of natural clay attapulgite, 18.85% of calcium lignosulfonate, 55% of acrylic acid, 25% of acrylamide, 0.5% of ammonium persulfate and 0.15% of N,N'-methylenebisacrylamide; The calcium lignosulfonate taken is mixed with a calcium lignosulfonate aqueous solution with a concentration of 40%, then zinc sulfate heptahydrate is weighed according to 30% of the calcium lignosulfonate quality, and zinc sulfate heptahydrate is added to the lignosulfonate solution. Calcium acid aqueous solution, stirring at room temperature for 2 hours, standing still, filtering to obtain zinc lignosulfonate solution; combining and dispersing natural clay attapulgite and zinc lignosulfonate solution in water to form a mixed solution, adding acrylic acid to the mixture solution, and then use sodium hydroxide to adjust the pH value of the mixed solution after adding acrylic acid to 4 to form a solution, add acrylamide to the solution, stir and disperse for 5 m...

Embodiment 2

[0044] According to mass percentage, take 0.9% of natural clay attapulgite, 15% of calcium lignosulfonate, 60.5% of acrylic acid, 21.8% of acrylamide, 1.5% of ammonium persulfate and 0.3% of N,N'-methylenebisacrylamide; The calcium lignosulfonate taken is mixed with a calcium lignosulfonate aqueous solution with a concentration of 35%, then zinc sulfate heptahydrate is weighed according to 36% of the calcium lignosulfonate quality, and zinc sulfate heptahydrate is added to the lignosulfonate Lignosulfonate aqueous solution, stirred at room temperature for 3 hours, left to stand, and filtered to obtain a zinc lignosulfonate solution; the natural clay attapulgite and zinc lignosulfonate solution were combined and dispersed in water to form a mixed solution, and the obtained Add the obtained acrylic acid into the mixed solution, and then use sodium hydroxide to adjust the pH of the mixed solution after adding the acrylic acid to 6 to form a solution, add the obtained acrylic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com