Steel rail grinding wheel allowing less grinding smoke and dust and production method thereof

A grinding and grinding wheel technology, which is applied in the direction of grinding/polishing equipment, grinding devices, abrasives, etc., can solve the problems of system pollution that cannot be eradicated, and achieve the advantages of improving grinding sharpness, reducing production, and high wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

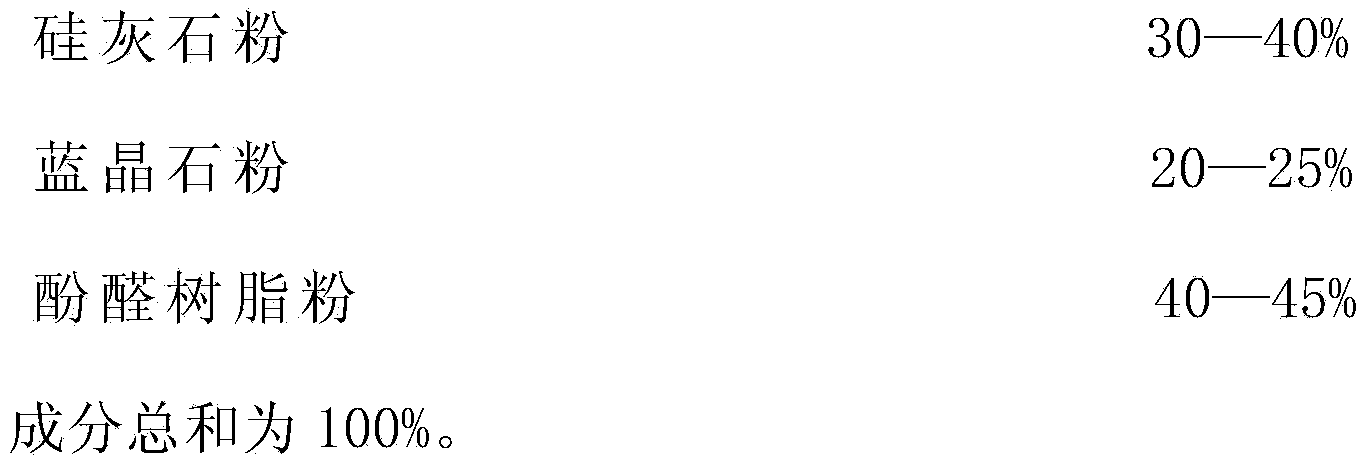

[0039] A method for preparing a steel rail grinding wheel with low grinding smoke and dust, the preparation steps are as follows: 1. Prepare abrasives. 90% of the zirconium corundum abrasive and 10% of the white corundum abrasive are fully mixed evenly, and the abrasive is obtained by weight percentage. 2. Configure the binder. 40% of wollastonite powder, 20% of kyanite powder and 40% of phenolic resin powder are mixed uniformly by dry method, and the binder is obtained by weight percentage. 3. Mixing. First use furfural to evenly wet the abrasive, the weight ratio of furfural to abrasive is 1:100, take 78% of abrasive and 22% of binder and mix evenly, calculated by weight percentage. 4. Forming. Put the mixture into the mold, hot press at 180°C for 35-40 minutes, and then release the mold to obtain a grinding wheel blank. 5. Dry. The grinding wheel blank is hardened in an oven, and fully hardened at 180°C for 5 hours to obtain a finished grinding wheel.

[0040] The per...

Embodiment 2

[0043] A method for preparing a steel rail grinding wheel with low grinding smoke and dust, the preparation steps are as follows: 1. Prepare abrasives. Fully mix 94% of zirconium corundum abrasive and 6% of white corundum abrasive to obtain the abrasive by weight percentage. 2. Configure the binder. Mix 32% of wollastonite powder, 25% of kyanite powder, and 43% of phenolic resin powder in a dry method to obtain a binder by weight percentage. 3. Mixing. Wet the abrasive evenly with furfural first, the weight ratio of furfural to abrasive is 1:100. Take 82% of the abrasive material and 18% of the bonding agent and mix evenly, calculated by weight percentage, and mix uniformly, calculated by weight percentage. 4. Forming. Put the mixture into the mold, hot press at 180°C for 35-40 minutes, and then release the mold to obtain a grinding wheel blank. 5. Dry. The grinding wheel blank is hardened in an oven, and fully hardened at 180°C for 5 hours to obtain a finished grinding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Molding density | aaaaa | aaaaa |

| Molding density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com