Difficult-to-machine material forming grinding cooling state monitoring device

A technology of material forming and cooling state, used in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as burns, and achieve the effect of improving efficiency and solving burns

Active Publication Date: 2016-08-10

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to provide a monitoring device for the cooling state of forming grinding of difficult-to-machine materials, which can monitor the cooling state of forming and grinding of difficult-to-machine materials, record corresponding data, and establish the surface temperature and coolant state of the processed workpiece The relationship between them provides a basis for the optimization of grinding process parameters and cooling methods, so as to further solve the problem of burns on the workpiece surface during the forming grinding process of difficult-to-machine materials, and improve the efficiency of forming grinding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

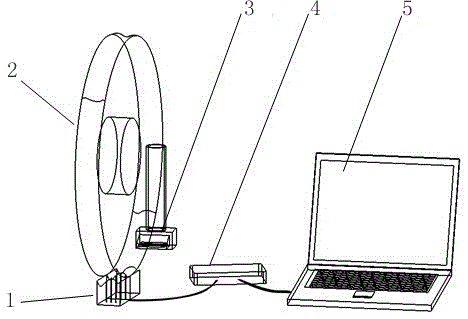

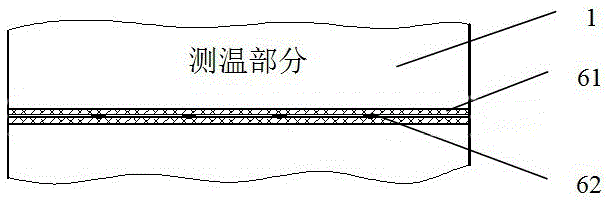

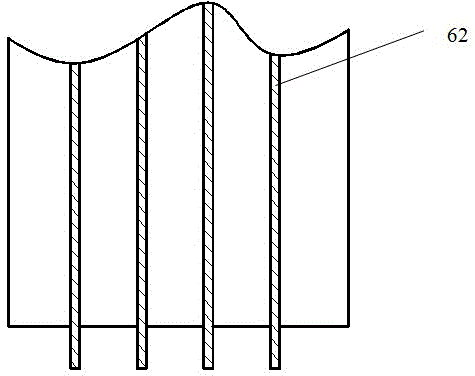

The invention discloses a forming grinding cooling state monitoring device for a material difficult to process. The forming grinding cooling state monitoring device comprises a temperature measurement part, a coolant pressure measurement part, a data acquisition card and a computer. Signals measured by the temperature measurement part and the coolant pressure measurement part are collected by the data acquisition card and then transmitted to the computer through a data line to be stored and processed. After stored and processed through the computer, the collected data can provide the basis for optimization of grinding process parameters and a cooling mode, the problem of burning of the workpiece molded surface in the forming grinding process of the material difficult to process is further solved, and forming grinding efficiency is improved.

Description

technical field The invention relates to an industrial processing process monitoring device, in particular to a cooling state monitoring device for high-efficiency forming grinding of difficult-to-process materials. Background technique The biggest problem in slow grinding of difficult-to-machine materials is grinding burns, especially sudden burns. At first, this phenomenon was not well explained theoretically. It was not until Professor Andrew of the University of Bristol introduced the boiling heat transfer technology in the field of thermal engineering in the 1970s that this phenomenon was explained. It points out that in the slow grinding process, when the grinding heat flux is close to but not exceeding the critical heat density, the grinding fluid in the grinding arc area is in the stage of nucleate boiling, and the surface temperature of the workpiece at this time can be maintained below 120-130 °C , and when the grinding arc area exceeds the critical heat flux dens...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B49/14B24B49/00

Inventor 赵正彩傅玉灿徐九华张志伟平波

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com