Method and device for growing bismuth selenide single crystal film on silicon substrate

A bismuth selenide single crystal and silicon substrate technology, applied in ion implantation plating, coating, electrical components, etc., can solve the problems of high cost and high lattice mismatch, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1.Bi 2 Se 3 Growth of Single Crystal Thick Film

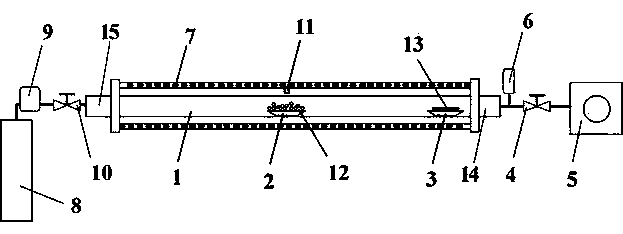

[0051] in such as figure 1 The specific steps for growing a bismuth selenide single crystal thin film on a silicon substrate with a thickness exceeding 200nm are as follows:

[0052] The highly pure (99.999%) compound microchip Bi 2 Se 3 The evaporation source 12 is placed in the quartz crucible 2 located in the center of the quartz tube 1 in the vacuum tube furnace body, and the area after cleaning and passivation process is 1×1 cm 2 The (111) oriented silicon substrate 13 is placed on the movable quartz sample holder 3 near the first nozzle 14, and the quartz sample holder 3 is moved so that the distance between the center of the Si substrate 13 and the right port of the quartz tube 1 is 15 cm.

[0053] After sealing the quartz tube 1, open the stop valve 4, and use the vacuum pump 5 located at one end of the vacuum tube furnace to evacuate the quartz tube 1 to a vacuum. Observe the vacuum gauge 6. When...

Embodiment 2

[0064] Example 2 Bi 2 Se 3 Growth of Single Crystal Ultrathin Films

[0065] in such as figure 1 The specific steps for growing a bismuth selenide single crystal thin film on a silicon substrate with a thickness of 20nm are as follows:

[0066] High-purity (99.99%) compound powder Bi 2 Se 3 The evaporation source 12 is placed in the quartz crucible 2 located in the center of the quartz tube 1 in the vacuum tube furnace body, and the area after the chemical cleaning and passivation process is 0.5 × 1cm 2 The (111) oriented silicon substrate 13 is placed on the movable quartz sample holder 3, the long side of the silicon substrate is adjusted to be perpendicular to the axial direction of the quartz tube, and the quartz sample holder 3 is moved so that the center of the silicon substrate 13 is at a distance from the quartz tube. 1 The distance between the ports on the right side is 12cm.

[0067] After the quartz tube 1 is sealed, the stop valve 4 is opened, and the quar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com