System and method for monitoring electrophoresis based on industrial Ethernet

A monitoring system and Ethernet technology, applied in the field of Ethernet-based monitoring systems, can solve the problems of long time-consuming, difficult to save, and scattered data, and achieve the effect of easy troubleshooting, easy storage, and centralized storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

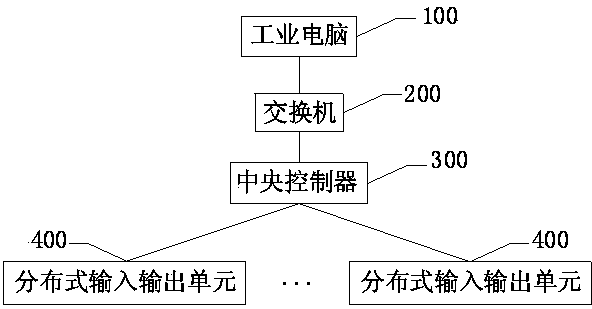

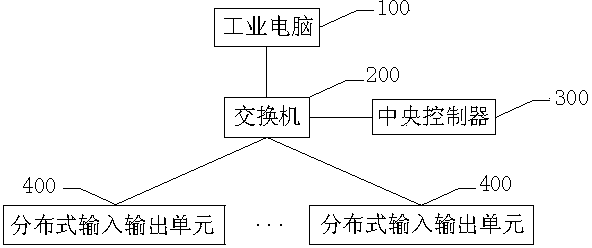

[0024] Such as figure 1 As shown, an industrial Ethernet-based electrophoresis monitoring system includes: an industrial computer 100 , a central controller 300 and a plurality of distributed input and output units 400 . A switch 200 may also be set between the industrial computer 100 and the central controller 300 . Among them, the industrial computer 100 is used to monitor the electrophoresis production line equipment and display the production status information in real time, and can remind the staff when the production status information is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com