A flexible workpiece storage device

A technology for storage devices and workpieces, applied in tool storage devices, manufacturing tools, workshop equipment, etc., can solve the problems of single storage of workpieces and inconvenient access, and achieve the effects of improving adaptability, protecting the surface quality of workpieces, and eliminating slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

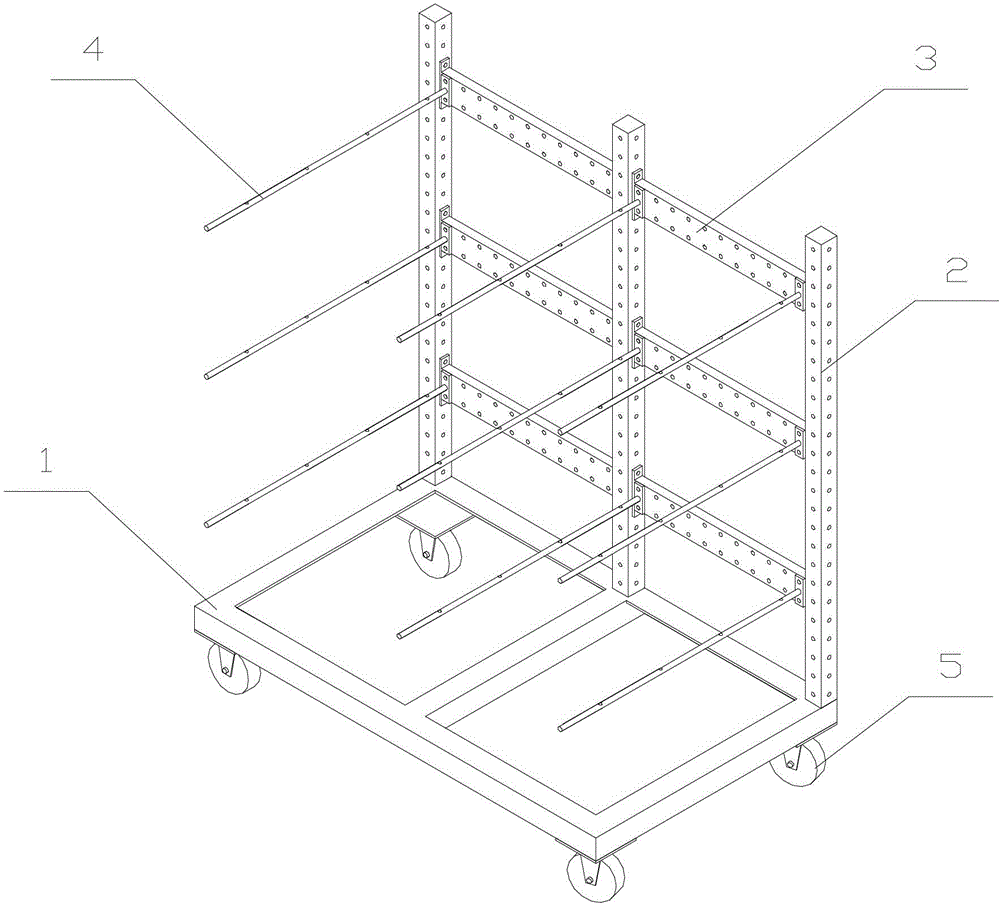

[0019] Embodiment 1: A kind of flexible workpiece storage device in this embodiment 1 is used to store workpieces such as automobile mufflers, such as figure 1 As shown, the base includes a base 1, the base has a rectangular structure, and the bottom is equipped with a universal caster 5, and three columns 2 are installed on one side of the base, and three beams 3 are respectively fixed between the columns, and the two ends of the beam are respectively fixed with the columns. , the beam and the column constitute the supporting surface; the beam is a square tube structure, and there are two rows of horizontal mounting holes on the beam, each row of mounting holes is evenly distributed, and the row spacing of the mounting holes is equal to the hole spacing of the mounting holes. There are several storage racks perpendicular to the support surface; one end of the storage rack is fixedly connected with a mounting plate, and the mounting plate is designed with fixing holes. The spac...

Embodiment 2

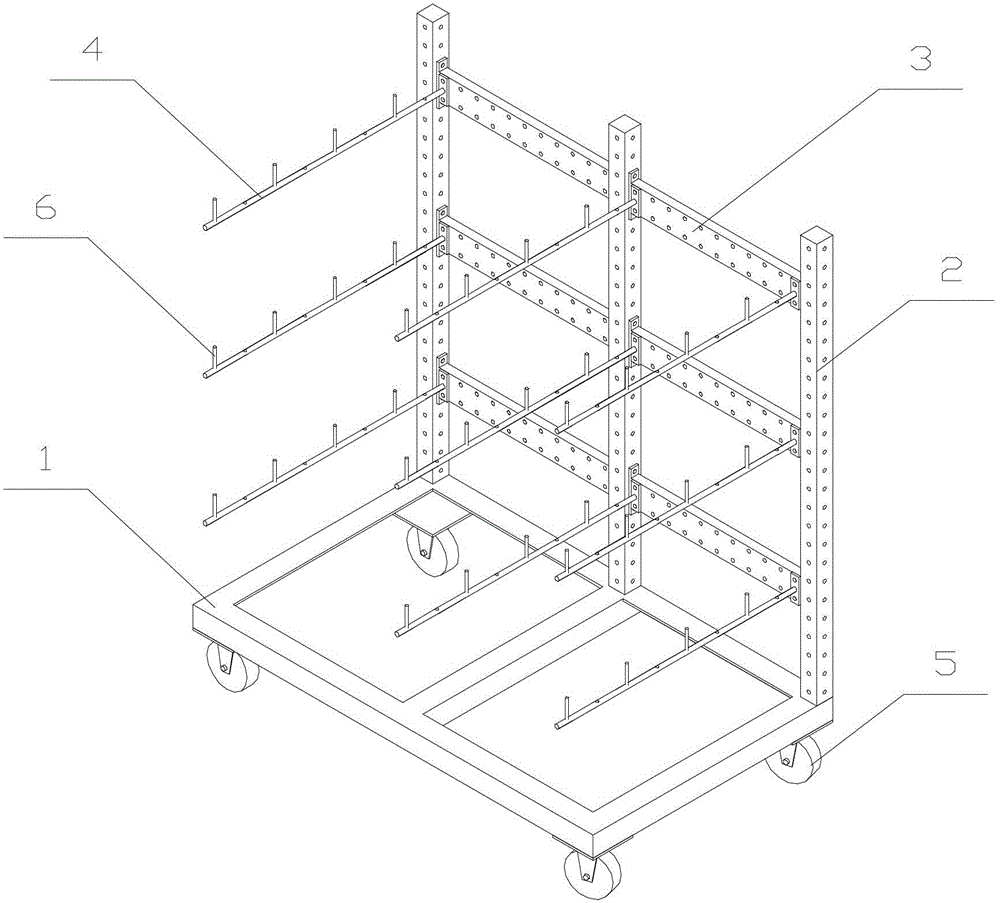

[0022] Embodiment 2: A kind of flexible workpiece storage device of this embodiment 2 is used to store workpieces such as automobile mufflers, such as figure 2 As shown, including the base, three uprights are installed on one side of the base, and three beams are fixedly connected between the uprights. A number of positioning screw holes evenly distributed and on the same straight line, the positioning screw holes on the storage rack face upward, and a positioning short rod with external threads is installed on the positioning screw holes, and the external threads match the internal threads of the positioning screw holes ;The short positioning rod is covered with a non-slip rubber protective layer. Due to the existence of the short positioning rod, the workpieces placed on the storage rack are neatly arranged, and the surface of the workpiece will not be scratched or damaged due to mutual extrusion or collision, and the non-slip rubber protection The layer can also reduce the...

Embodiment 3

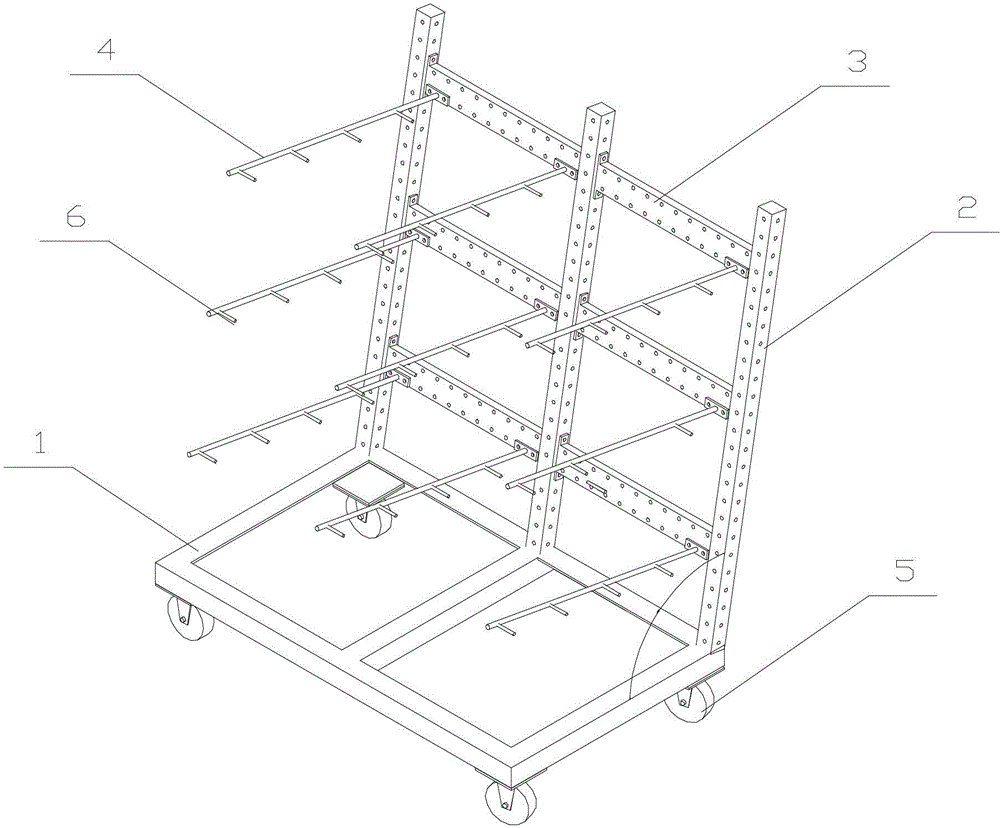

[0023] Embodiment 3: A kind of flexible workpiece storage device of this embodiment 3 is used to store workpieces such as automobile mufflers, such as image 3 As shown, including the base, three uprights are installed on one side of the base, and three beams are respectively fixed between the uprights. The beams and uprights form a supporting surface, and the angle between the supporting surface and the plane of the base is 105°, and a storage rack is installed on the beams. , the positioning screw holes on the storage rack face the same side, so that the positioning short rod on the storage rack lies flat and consistent with the storage plane, forming a horizontal and large storage plane, which can meet the storage requirements of long workpieces. The third embodiment of this embodiment Other parts are similar to the corresponding parts of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com