Sewage COD soft measurement method based on output observer

A soft measurement and observer technology, applied in the field of soft measurement of COD effluent of sewage treatment system, can solve the problems of complex reaction process, difficult measurement of key variables, strong nonlinear relationship, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

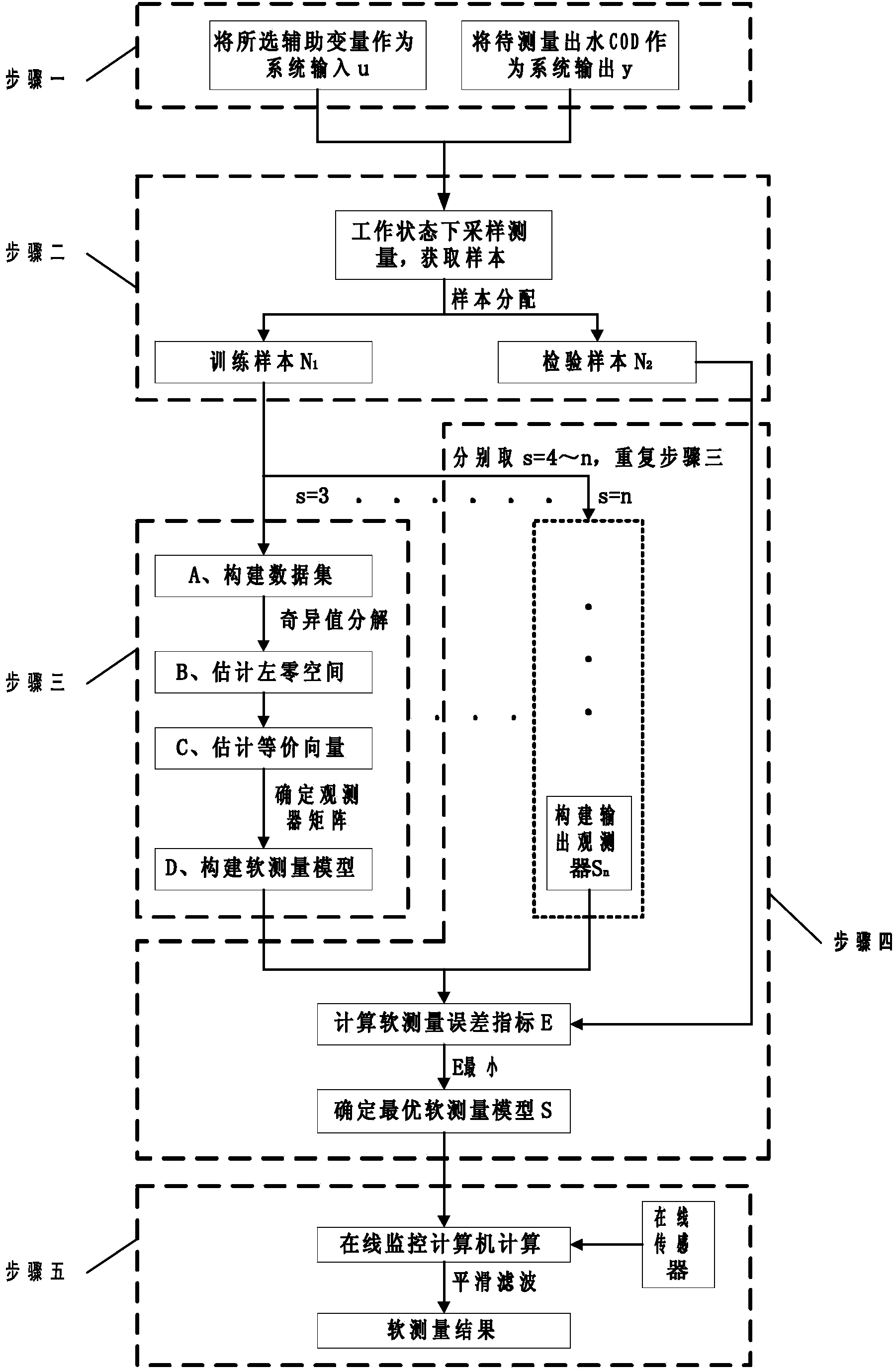

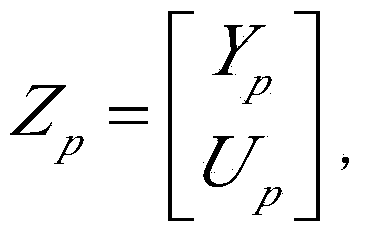

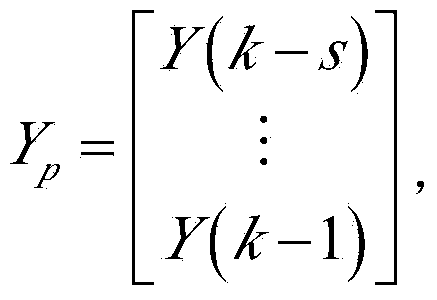

[0049] Specific implementation mode one: combine figure 1 and Figure 2 illustrate the present embodiment. A sewage COD soft-sensing method based on an output observer is carried out according to the following steps:

[0050] Step 1. Select auxiliary variables and variables to be measured: select TOC, DO, ORP, pH, T, HRT and r as auxiliary variables, and set them as u 1 ,...,u 7 , set the effluent COD as y, and the y is the variable to be measured; define the sewage treatment process as a reaction system, and the system input is u=[u 1… u 7 ]∈R l , l=7, the system output y∈R m , m=1; among them, TOC is the total organic carbon content of the influent, DO is the dissolved oxygen in the reaction tank, ORP is the oxidation-reduction potential, pH is the acidity and alkalinity, T is the water temperature, HRT is the hydraulic retention time, and r is the reflux ratio;

[0051] Step 2, data collection: use sensors to collect data samples of auxiliary variables of sewage and va...

specific Embodiment approach 2

[0086] Specific implementation mode two: the difference between this implementation mode and specific implementation mode one is: step D builds the soft sensor model described in

[0087] If there is an online instrument, then It is the online instrument reading, and the soft measurement result is the optimized measurement data;

[0088] If there is no online instrument, then Median obtained for offline sampling. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0089] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the online filter described in step F online filtering is a smoothing filter. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com