High anti-seismic perforated tray for nuclear power plant nuclear island

A high-seismic, nuclear power plant technology, applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of increased bridge cost, low seismic performance, and low safety performance, so as to improve strength and bearing capacity, improve Anti-corrosion ability, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

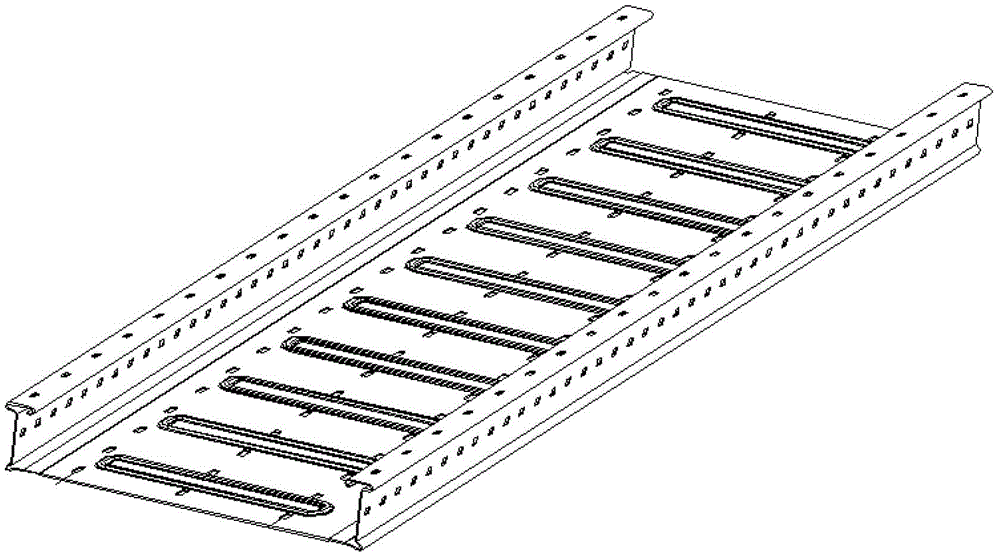

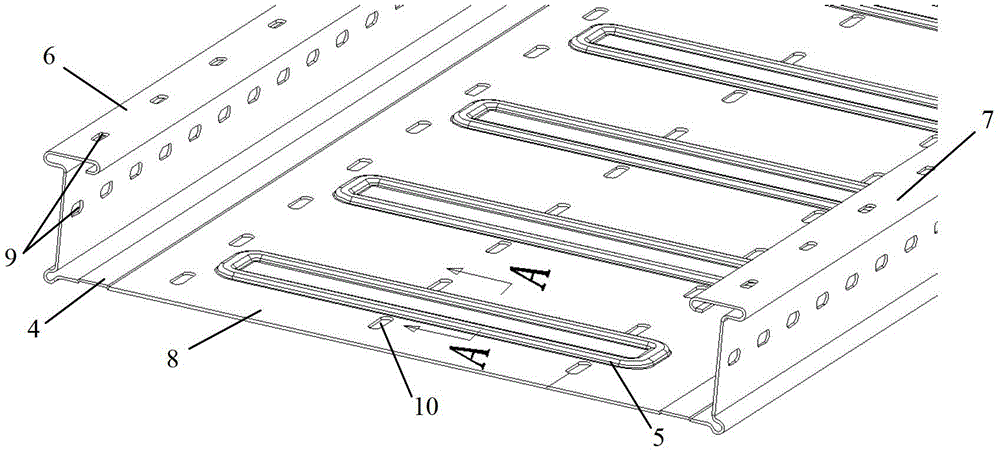

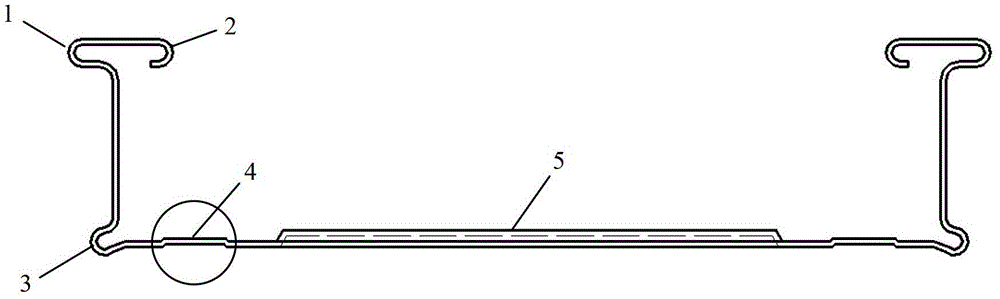

[0028] Such as Figure 1-Figure 5 As shown, the third-generation nuclear power plant nuclear island high-seismic perforated pallet provided by the present invention includes two ladder sides 6, 7 and a bottom plate 8, and the ladder sides 6, 7 and the bottom plate 8 are stamped from a whole plate, and the plate can be made of Carbon steel, stainless steel and other plates that can meet the strength requirements. The bottom plate 8 is provided with an annular reinforcing rib 5 and a longitudinally extending through rib 4 . There are several annular reinforcing ribs 5 arranged evenly in the middle of the bottom plate. The annular reinforcing ribs are oblong in structure and vertical to the through ribs 4. The section of the annular reinforcing ribs 5 is n-shaped. The cross-section of the tendon is as Figure 4 As shown, the cross-sectional view of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com