Membrane technology-based ionic rare earth ore extraction technology and device therefor

An ionic rare earth ore and extraction process technology, which is applied in the field of rare earth extraction technology of ionic rare earth ore, can solve the problems of low rare earth ion concentration and small floor space, and achieve good water quality, reduce floor space, and reduce production and processing. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

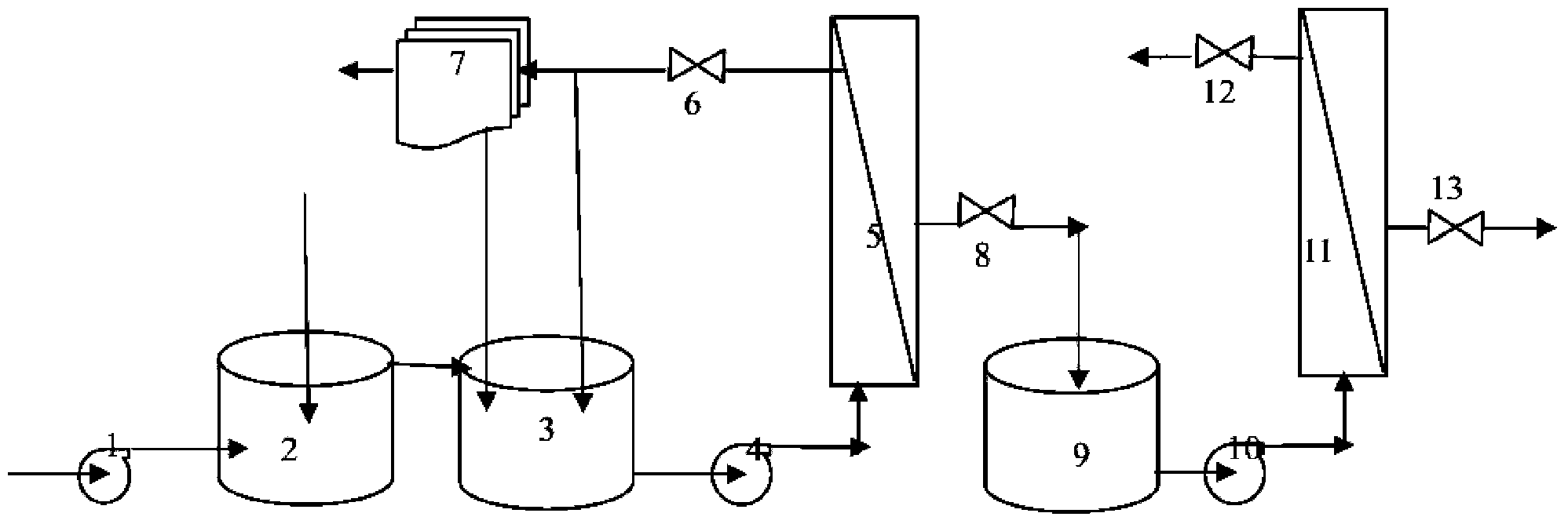

[0041] Such as figure 1 As shown, a kind of membrane separation integrated device applied in the rare earth extraction process of ionic rare earth ore according to the present invention has a structure of:

[0042] Comprising feed pump 1, settling tank 2, ultrafiltration membrane circulation tank 3, ultrafiltration membrane circulation pump 4, ultrafiltration membrane assembly 5 connected in sequence, the permeation side of described ultrafiltration membrane assembly 5 is connected to ultrafiltration membrane cleaning Liquid tank 9, the cut-off side of ultrafiltration membrane module 5 is connected to ultrafiltration membrane circulation tank 3, and ultrafiltration membrane clear liquid tank 9 is connected to nanofiltration membrane module 11 by nanofiltration circulation pump 10, and the cut-off side of ultrafiltration membrane module 5 Also connected to the plate and frame filter press 7, the permeation side of the plate and frame filter press 7 is connected to the ultrafil...

Embodiment 2

[0046] use as figure 1 device shown.

[0047] The ionic adsorption rare earth ore of a rare earth mine in Yunnan was impregnated. The impregnation process was the same as that of the control example. The impregnation agent used was a mixture of ammonium chloride and ammonium sulfate at a ratio of 1:1. The rare earth content of the obtained impregnation solution was is 0.12 g / L, pump the leachate into the settling tank 2 for slag removal, adjust the pH to about 4 with ammonia water b, and react for 15 minutes, take the supernatant and enter the ultrafiltration membrane module 5 for solid-liquid separation. The filter membrane adopts a ceramic ultrafiltration membrane made of zirconia, and the average pore size of the ceramic ultrafiltration membrane is 0.05 μm. The ultrafiltration membrane module 5 performs constant flow filtration, and the control filtration flux is 500 L / m 2 h, the pressure is 0.5 MPa, the flow velocity on the membrane surface is 6 m / s, and a recoil device...

Embodiment 3

[0050] use as figure 1 device shown.

[0051] The ionic adsorption type rare earth ore of a rare earth mine in Yunnan was impregnated. The impregnation process was the same as that of the control example. The impregnation agent used was a mixture of ammonium chloride and ammonium sulfate at a ratio of 1:1. The rare earth content of the obtained impregnation solution was is 0.12 g / L, pump the leachate into the slag removal settling tank 2, adjust the pH to about 5 with ammonia water b, and react for 30 minutes, take the supernatant and enter the ultrafiltration membrane module 5 for solid-liquid separation, and the ultrafiltration membrane The ceramic ultrafiltration membrane is made of titanium oxide, and the average pore size of the ceramic ultrafiltration membrane is 0.02 μm. The ultrafiltration membrane module 5 performs constant flow filtration, and the control filtration flux is 150 L / m 2 h, the pressure is 0.1MPa, the membrane surface flow velocity is 3 m / s, and a rec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com