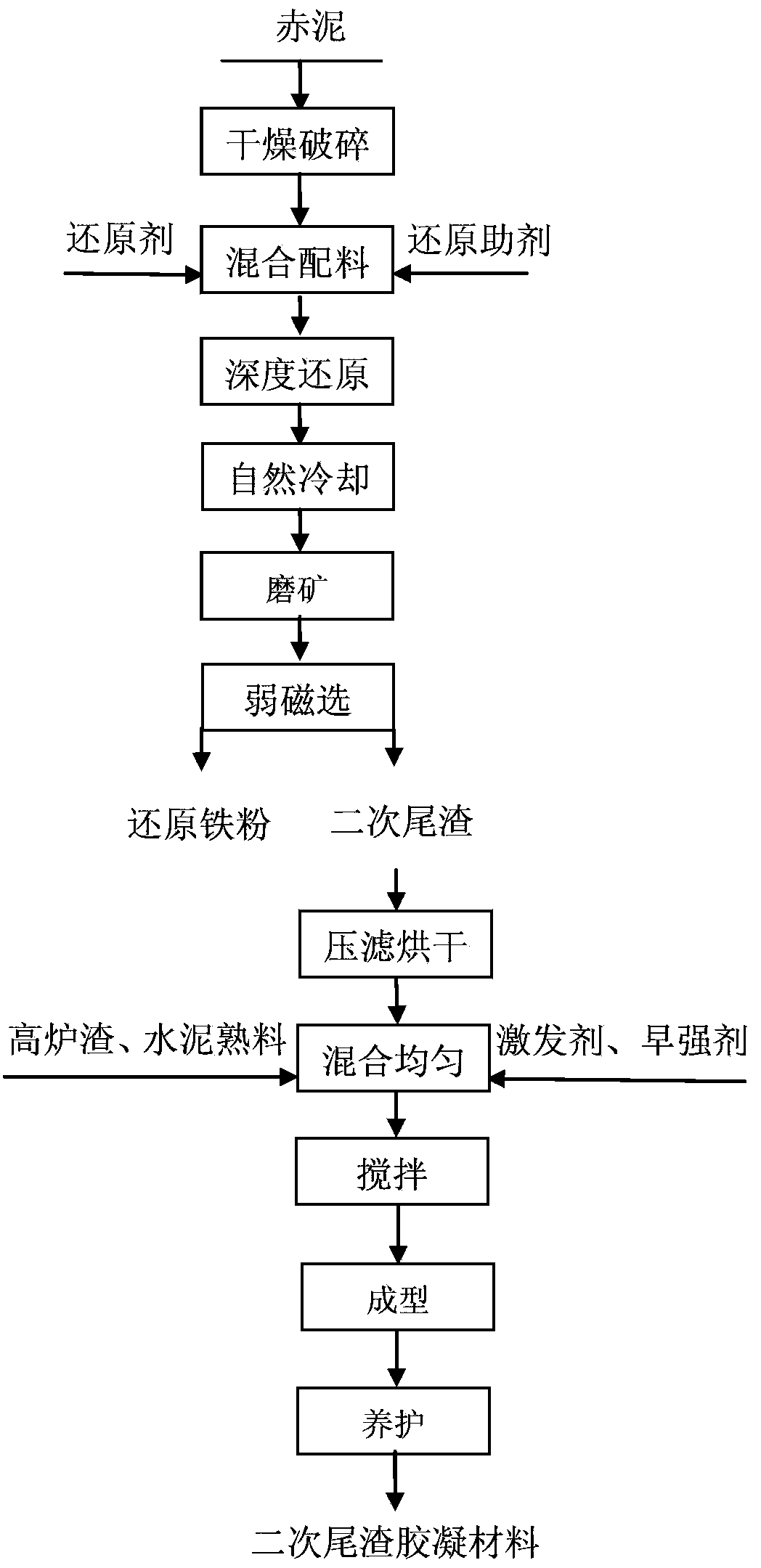

Method used for extracting iron from red mud by drastic reduction and method used for preparing gel material from secondary tailings

A cementitious material and deep technology, applied in the field of comprehensive utilization of resources, can solve the problems of low-grade iron-containing red mud being economically unreasonable, increasing production costs, and high smelting temperature, so as to solve the problem of red mud stockpiling, easy control and process. simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Deep reduction and iron extraction. Red mud contains 37.10% iron and contains Al 2 o 3 17.10%, containing SiO 2 7.46%, including CaO1.69%. Deep reduction conditions: red mud: coke: CaO=100:11:5, mixed evenly and kept at a reduction temperature of 1250°C for 60 minutes, then taken out and cooled naturally; Grinding at a grinding concentration of 65% to a fineness of -0.074 mm greater than 90%, the magnetic field strength is 111.44kA m -1 Under the conditions of magnetic separation, reduced iron powder with an iron grade of 91.23% and an iron recovery rate of 93.13% was obtained. Among them, the fixed carbon content of coke is 85.43%, the ash content is 12.5%, the volatile content is 1.21%, and the moisture content is 11.68%.

[0016] (2) Preparation of cementitious material from secondary tailings: filter and dry the secondary tailings after wet grinding and weak magnetic separation in step (1) and mix with blast furnace slag, cement clinker, activator and early...

Embodiment 2

[0018] (1) Deep reduction and iron extraction. Red mud contains 39.04% iron and contains Al 2 o 3 13.16%, containing SiO 2 8.02%, containing CaO1.55%. Deep reduction conditions: red mud: bituminous coal: CaO=100:17.5:12.5, mixed evenly and kept at a reduction temperature of 1350°C for 50 minutes, then taken out and cooled naturally; Grinding at a grinding concentration of 65% to a fineness of -0.074 mm greater than 90%, the magnetic field strength is 111.44kA m -1 Under the condition of magnetic separation, the reduced iron powder with iron grade of 92.58% and iron recovery rate of 95.05% was obtained. Among them, the fixed carbon content of bituminous coal is 67.83%, the ash content is 12.02%, the volatile content is 18.45%, and the moisture content is 1.48%.

[0019] (2) Preparation of cementitious material from secondary tailings: filter and dry the secondary tailings after wet grinding and weak magnetic separation in step (1) and mix with blast furnace slag, cement cl...

Embodiment 3

[0021] (1) Deep reduction and iron extraction. Red mud contains 37.10% iron and contains Al 2 o 3 17.10%, containing SiO 2 7.46%, including CaO1.69%. Deep reduction conditions: red mud: coke: CaF 2 : Na 2 CO 3 =100:11:5:10, after mixing evenly, keep it warm for 60min at the reduction temperature of 1250°C, then take it out and cool it naturally; grind the ore at a grinding concentration of 65% until the fineness -0.074mm is greater than 90%, and the magnetic field strength is 111.44kA·m -1 Under the conditions of magnetic separation, the reduced iron powder with an iron grade of 93.01% and an iron recovery rate of 92.84% was obtained. Among them, the fixed carbon content of coke is 85.43%, the ash content is 12.5%, the volatile content is 1.21%, and the moisture content is 11.68%.

[0022] (2) Preparation of cementitious material from secondary tailings: filter and dry the secondary tailings after wet grinding and weak magnetic separation in step (1) and mix with blast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com