Preparation method of phosphorylated peptidoglycan

A technology of phosphorylated peptidoglycan and peptidoglycan, applied in biochemical equipment and methods, methods based on microorganisms, microorganisms, etc., can solve problems that have not been reported before, and achieve improved enzyme digestion range, mild reaction conditions, Significant effect of immune effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

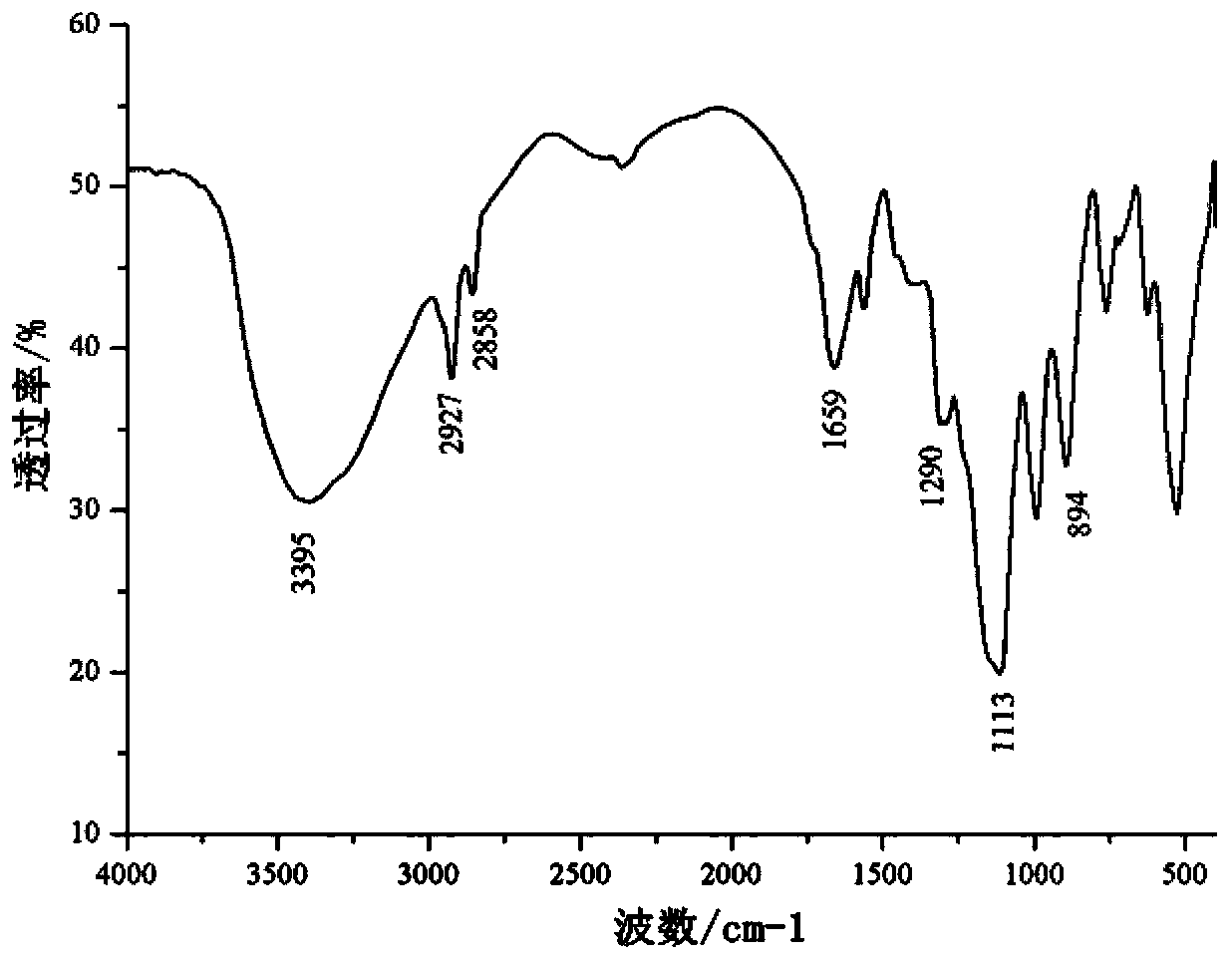

Method used

Image

Examples

Embodiment 1

[0036] The invention uses common commercially available Lactobacillus acidophilus bacteria powder as a raw material to extract the peptidoglycan. First, inoculate 2mg of bacterial powder into 200mL of MRS liquid medium, and culture it statically at 37°C for 24 hours to activate the strain. A method for preparing phosphorylated peptidoglycan of the present invention specifically includes the following steps:

[0037] (1) Preparation of peptidoglycan

[0038] a. Bacteria collection: Inoculate the activated Lactobacillus acidophilus into the MRS liquid medium with an inoculum volume of 4% by volume, culture it in a constant temperature incubator at 38.5°C for 20 hours, centrifuge at 6500r / min for 15min to collect the bacteria, and use distilled water repeatedly Wash until the cells are milky white; the preparation method of the MRS liquid medium is as follows: 10g of peptone, 10g of beef extract, 5g of yeast extract, 10g of glucose, 2g of triamine citrate, 2g of dipotassium hydro...

Embodiment 2

[0047] With embodiment 1, its difference is:

[0048] (1) Preparation of peptidoglycan

[0049] Inoculate the activated Lactobacillus acidophilus into the MRS liquid medium with an inoculation amount of 3% by volume, and culture it in a constant temperature incubator at 37°C for 16 hours, then centrifuge at 5000r / min for 20 minutes to collect the bacteria, and wash them repeatedly with distilled water until the bacteria are milky white Suspend the bacterium in a 40% hydrofluoric acid solution at a solid-to-liquid ratio of 1g:9ml, place it overnight at 4°C, and centrifuge at 7000r / min for 20min to collect the cell wall precipitate that does not contain teichoic acid, and wash the precipitate with distilled water until Neutral; dissolve the precipitate in chymotrypsin phosphate buffer at a solid-to-liquid ratio of 2g:5ml, shake on a shaker at 110r / min at 37°C for 17h, inactivate in a boiling water bath for 4min, centrifuge at 1500r / min for 6min, discard Remove the undissolved p...

Embodiment 3

[0055] With embodiment 1, its difference is:

[0056] (1) Preparation of peptidoglycan

[0057] Inoculate the activated Lactobacillus acidophilus into the MRS liquid medium with an inoculation amount of 5% by volume, and culture it in a constant temperature incubator at 40°C for 24 hours, then centrifuge at 8000r / min for 10 minutes to collect the bacteria, and wash them repeatedly with distilled water until the bacteria are milky white Suspend the bacterium in a 50% hydrofluoric acid solution at a solid-to-liquid ratio of 1g:9ml, place it overnight at 4°C, centrifuge at 9000r / min for 10min to collect the cell wall precipitate, and wash the precipitate with distilled water to neutrality; The solid-liquid ratio of 2g:5ml was dissolved in chymotrypsin phosphate buffer, shaken at 130r / min at 40°C for 15h, inactivated in a boiling water bath for 6min, centrifuged at 2500r / min for 4min, and the supernatant was placed at 12000r / min Centrifuge for 10 min, and wash the obtained precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com