Multifunctional accessory ingredient of drilling fluid

A kind of fluid additive and multi-functional technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of abnormal drilling operation, easy thickening of drilling fluid, excessive use of raw materials, etc., and achieves good filtration reduction. Loss, prevent sticking, reduce the effect of input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

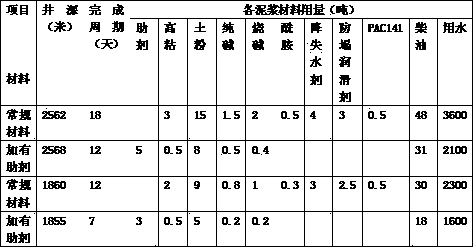

Image

Examples

Embodiment 1

[0015] A multifunctional drilling fluid additive, which is composed of the following raw materials by weight: 13 parts of anionic cellulose sodium salt, 4 parts of graphite powder, 10 parts of potassium humate, 9 parts of potassium chloride, 5 parts of small cations, 18 parts of polyacrylonitrile, 25 parts of medium molecular polymer, 2 parts of synergist.

[0016] The production process of the middle molecular polymer is to first mix acrylic acid and acrylamide in a weight ratio of 55:45, and form a mixture after distillation and dehydration; add 40% of the weight of the mixture to the mixture of sodium sulfate and 60% of It can be obtained after the acid anhydride is polymerized and grafted.

[0017] The synergist is composed of the following raw materials in weight ratio: ethylenediamine 20%, hydrogen peroxide 30%, vinyl monomer 40%, plasticizer 10%, the above raw materials are mixed and reacted at 80°C Serves in 4 hours.

Embodiment 2

[0019] A multifunctional drilling fluid additive, which is composed of the following raw materials by weight: 17 parts of anionic cellulose sodium salt, 6 parts of graphite powder, 14 parts of potassium humate, 11 parts of potassium chloride, 6 parts of small cations, 22 parts of polyacrylonitrile, 35 parts of medium molecular polymer, 3 parts of synergist.

[0020] The production process of the middle molecular polymer is to first mix acrylic acid and acrylamide in a weight ratio of 55:45, and form a mixture after distillation and dehydration; add 40% of the weight of the mixture to the mixture of sodium sulfate and 60% of It can be obtained after the acid anhydride is polymerized and grafted.

[0021] The synergist is composed of the following raw materials in weight ratio: ethylenediamine 20%, hydrogen peroxide 30%, vinyl monomer 40%, plasticizer 10%, the above raw materials are mixed and reacted at 80°C Serves in 4 hours.

Embodiment 3

[0023] A multifunctional drilling fluid additive, which is composed of the following raw materials by weight: 15 parts of anionic cellulose sodium salt, 5 parts of graphite powder, 12 parts of potassium humate, 10 parts of potassium chloride, 5.5 parts of small cations, 20 parts of polyacrylonitrile, 30 parts of medium molecular polymer, 2.5 parts of synergist.

[0024] The production process of the middle molecular polymer is to first mix acrylic acid and acrylamide in a weight ratio of 55:45, and form a mixture after distillation and dehydration; add 40% sodium sulfate and 60% maleic acid to the mixture respectively. It can be obtained after the acid anhydride is polymerized and grafted.

[0025] The synergist is composed of the following raw materials in weight ratio: ethylenediamine 20%, hydrogen peroxide 30%, vinyl monomer 40%, plasticizer 10%, the above raw materials are mixed and reacted at 80°C Serves in 4 hours.

[0026] apparent viscosity API filtration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com