Wear-resistant UV (ultraviolet) photocuring woodware paint composition

A technology of wood coatings and compositions, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of high wear resistance of paint films, and achieve the effects of ensuring sanding resistance, low density, and guaranteed sanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

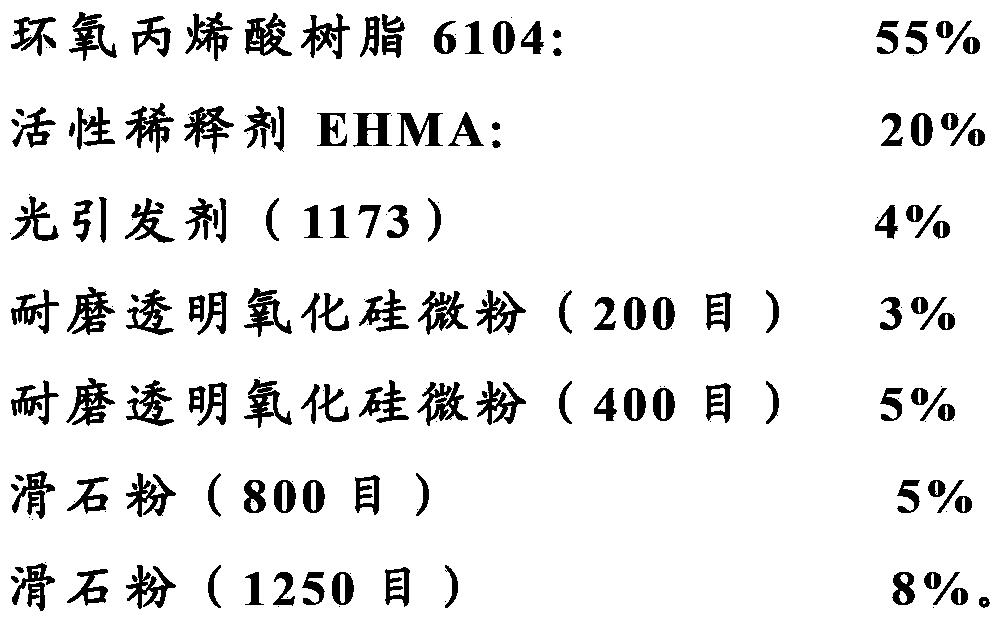

[0028] This example provides a kind of wear-resisting UV photocuring wood coating composition, and its raw material formula is as follows in terms of mass percentage:

[0029]

[0030] The preparation method of the composition is as follows: according to the formula ratio, put the resin, diluent, and photoinitiator into the material bucket, start stirring, and put in 200 mesh transparent micropowder, 400 mesh transparent micropowder, and 800 mesh talc in sequence at a speed of 500r / min. powder, 1250 mesh talc powder, keep the rotation speed of 500r / min for 30 minutes, then increase the rotation speed to 1200r / min, disperse for 30 minutes, stop the machine, filter and pack with 80 mesh nylon filter, and the whole production process should be protected from light.

[0031] The main technical index of gained composition is as follows:

[0032] 1. Viscosity, cp / s 4500

[0033] 2. Abrasion, 750g / 500r 0.008

[0034] 3. Grinding property, 400# sandpaper is easy to grind

Embodiment 2

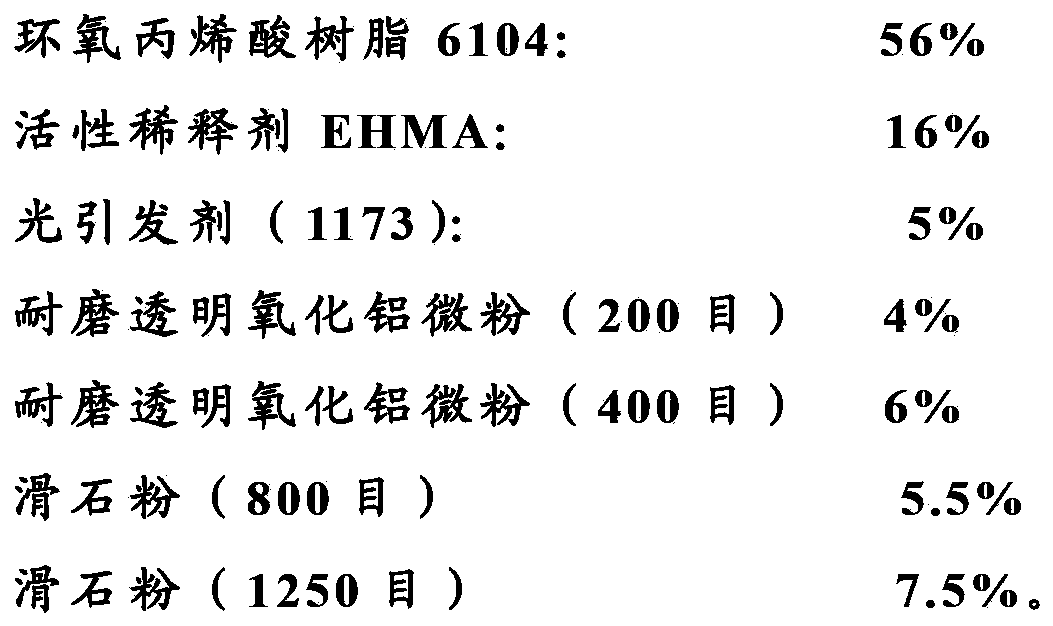

[0036] This example provides a kind of wear-resisting UV photocuring wood coating composition, and its raw material formula is as follows in terms of mass percentage:

[0037]

[0038] The preparation method of the composition is as follows: according to the formula ratio, put the resin and diluent into the material tank, start stirring, and put in 200 mesh transparent micropowder, 400 mesh transparent micropowder, 800 mesh talcum powder, 1250 mesh For talcum powder, keep the rotating speed of 400r / min for 35 minutes, then increase the rotating speed to 1100r / min, disperse for 35 minutes, stop the machine, filter and pack with 80-mesh nylon filter, and the whole production process should be protected from light.

[0039] The main technical index of gained composition is as follows:

[0040] 1. Viscosity, cp / s 4800

[0041] 2. Abrasion, 750g / 500r 0.007

[0042] 3. Grinding property, 400# sandpaper is easy to grind

Embodiment 3

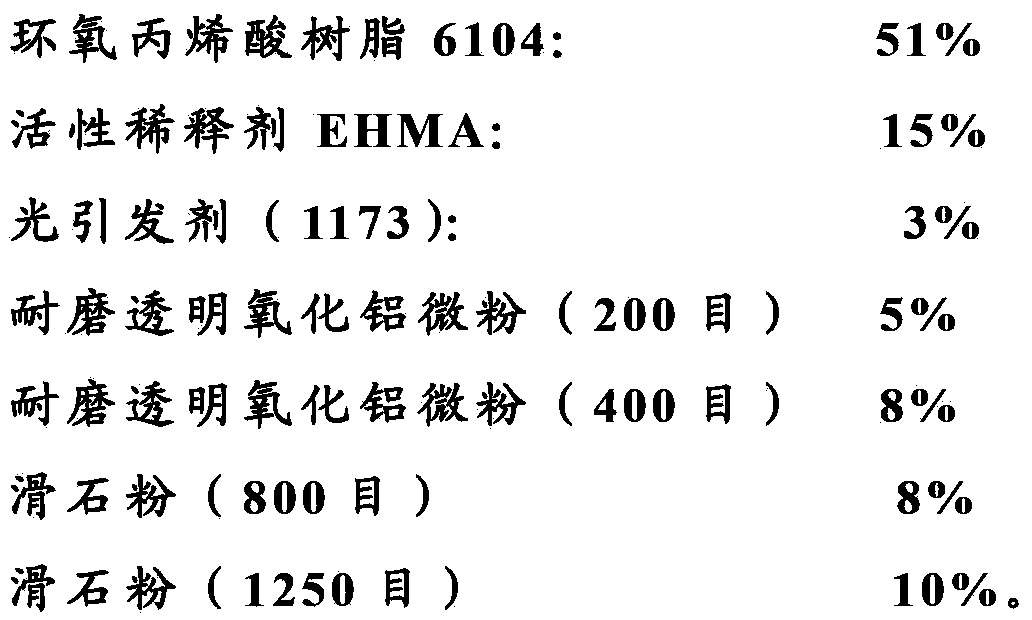

[0044] This example provides a kind of wear-resisting UV photocuring wood coating composition, and its raw material formula is as follows in terms of mass percentage:

[0045]

[0046] The preparation method of the composition is as follows: according to the formula ratio, put the resin and diluent into the material tank, start stirring, and put in 200 mesh transparent micropowder, 400 mesh transparent micropowder, 800 mesh talcum powder, 1250 mesh For talcum powder, keep the rotating speed of 400r / min for 25 minutes, then increase the rotating speed to 1100r / min, disperse for 35 minutes, stop the machine, filter and pack with 80-mesh nylon filter, and the whole production process should be protected from light.

[0047] The main technical index of gained composition is as follows:

[0048] 1. Viscosity, cp / s 4650

[0049] 2. Abrasion, 750g / 500r 0.008

[0050] 3. Grinding property, 400# sandpaper is easy to grind

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com