Dynamic vulcanized fluoroplastic/fluororubber/silicone rubber thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and fluororubber technology, which is applied in the field of dynamic vulcanized fluoroplastic/fluororubber/silicone rubber thermoplastic elastomer and its preparation, can solve the problems of poor low temperature resistance and achieve low processing energy consumption and good compatibility , the effect of good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

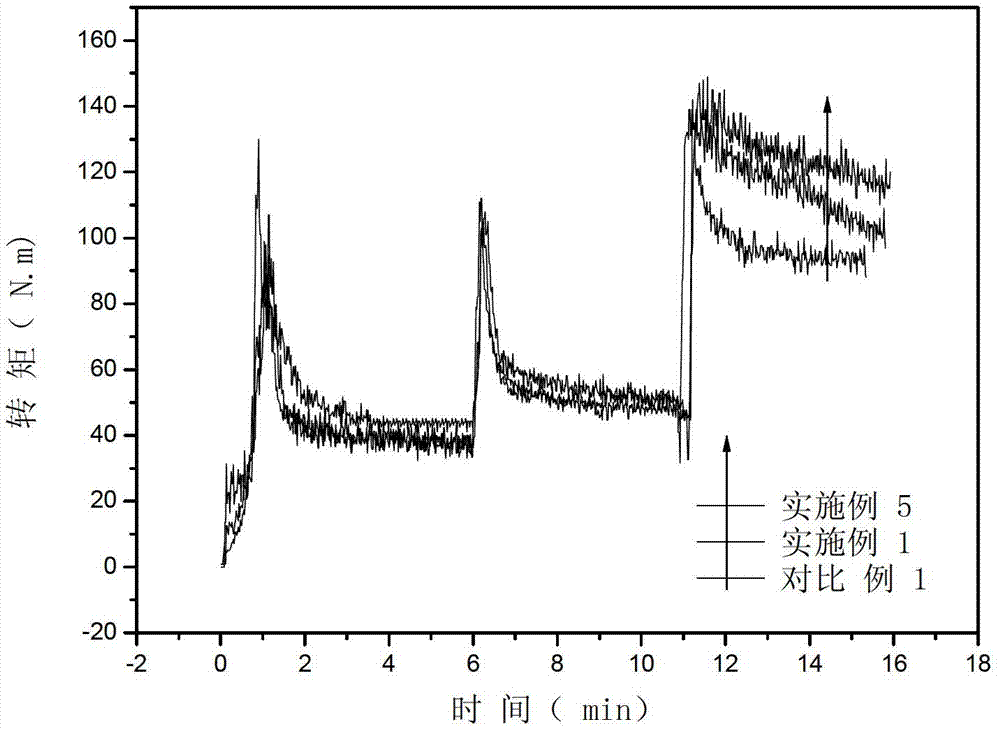

Embodiment 1

[0051] Polyvinylidene fluoride was selected as the matrix resin (502, Guangzhou Lichang), silicone rubber was used as general foundation silicone rubber (KE571-U, Japan Shin-Etsu), and fluorine rubber (F2463, Zhonghao Chenguang Chemical Research Institute). First, fluororubber (30g), magnesium oxide (1.5g) and calcium hydroxide (1.5g) were mixed evenly on the open mill, and then mixed with silicone rubber (90g) to make fluororubber silicone rubber compound. Add polyvinylidene fluoride (180g) into the Haake torque rheometer with a temperature of 170°C and a rotor speed of 60r / min, add fluororubber and silicone rubber compound after 6 minutes, and add hydroxyl fluorosilicone oil (3g after mixing for 3 minutes) ), continue mixing for 3 minutes, add vulcanizing agent dicumyl peroxide (0.3 g) and crosslinking aid triallyl isocyanurate (0.3 g) for dynamic vulcanization, continue blending for 6 minutes, and discharge. The samples were crushed into fine and uniform particles with a cr...

Embodiment 2

[0053] Polyperfluoroethylene propylene was selected as the matrix resin (Guangzhou Lichang), silicone rubber was used as general foundation silicone rubber (KE571-U, Japan Shin-Etsu), and fluororubber (F2403, Zhonghao Chenguang Chemical Research Institute). Preparation method: First, mix fluorine rubber (36g) and magnesium oxide (9g) uniformly on an open mill, and then mix them with silicone rubber (24g) to make a fluorine rubber silicone rubber compound. Add polyperfluoroethylene propylene (240g) to the Haake torque rheometer at a temperature of 290°C and a rotor speed of 90r / min, add fluororubber silicone rubber compound after 6 minutes, and add silicone oil (15g) after mixing for 3 minutes , continue mixing for 3 minutes and then add vulcanizing agent 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (DBPMH) (9g), triacryl isocyanurate and triacryl cyanuric acid The ester mixture (15g) was subjected to dynamic vulcanization, continued blending for 6 minutes, and discharged. The s...

Embodiment 3

[0055] Select polyvinylidene fluoride as the matrix resin (502, Lichang, Guangzhou), silicone rubber as the general basic silicone rubber (KE571-U, Japan Shin-Etsu), and fluorine rubber TFE-P-Vdf (200P, Asahi Glass Co., Ltd. Chemical Company) . First, fluororubber (30g), magnesium oxide (MgO) (15g) and calcium oxide (CaO) (7g) are mixed evenly on an open mill, and then mixed with silicone rubber (60g) to make fluororubber and silicone rubber. glue. Add polyvinylidene fluoride (210g) to the Haake torque rheometer at a temperature of 220°C and a rotor speed of 60r / min, add fluororubber silicone rubber compound after 3 minutes, and add fluorine oil (9g) after mixing for 3 minutes After continuing to mix for 3 minutes, add the vulcanizing agent dicumyl peroxide (2g) and N,N‐biscinnamylidene‐1,6‐hexamethylenediamine (3# vulcanizing agent) (1g), and the crosslinking agent triene Propyl isocyanurate (9g) was subjected to dynamic vulcanization, continued blending for 4 minutes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com