Low-temperature self-crosslinked water-based acrylate resin, and preparation method and application thereof

A water-based acrylate and methyl acrylate technology, used in applications, household appliances, inks, etc., can solve the problems of low gloss, poor water resistance of the coating film, insufficient cross-linking and curing of the coating film, etc., to achieve a wide range of applications, organic solvents low content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

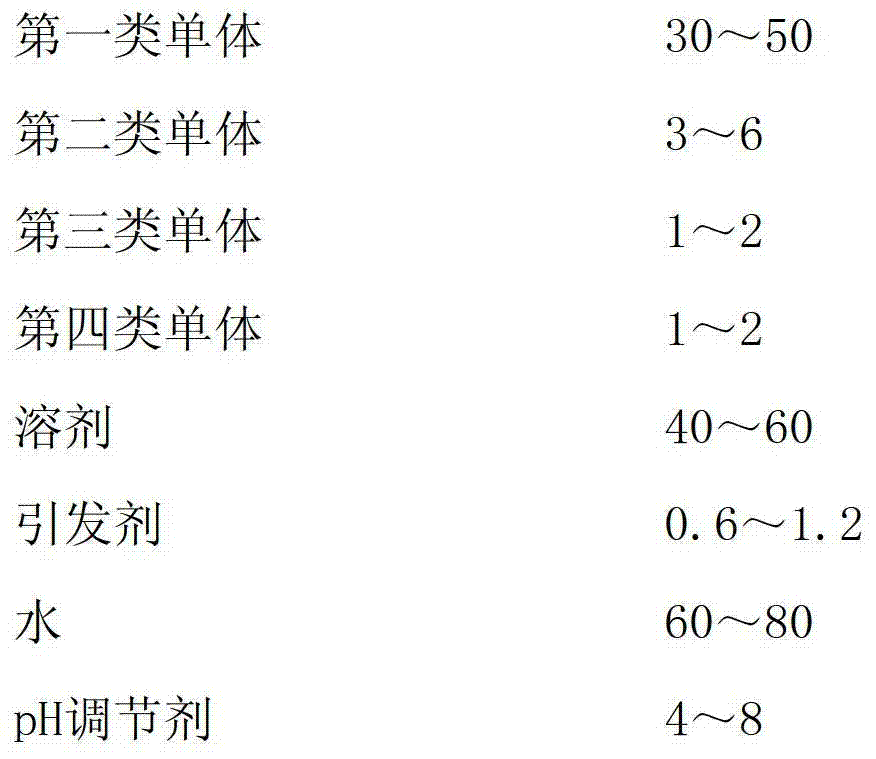

[0068] A low-temperature self-crosslinking water-based acrylate resin, in parts by weight, consists of the following raw materials:

[0069]

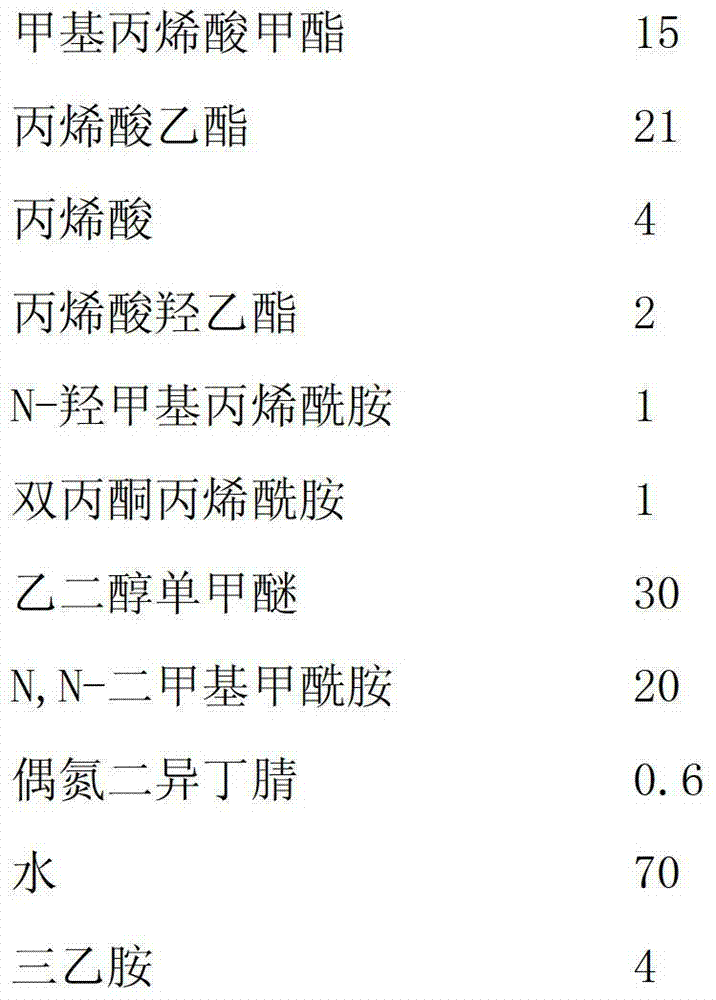

[0070]

[0071] The preparation steps are as follows:

[0072] (a) Add 30g of ethylene glycol monomethyl ether and 20g of N,N-dimethylformamide into a reactor with a reflux condenser, stir and raise the temperature to 60°C, and obtain a mixed solvent after the reflux is stable;

[0073] (b) Mix 4 g styrene, 15 g methyl methacrylate, 21 g ethyl acrylate, 4 g acrylic acid, 2 g hydroxyethyl acrylate, 1 g N-methylol acrylamide, 1 g diacetone acrylamide and 0.6 g azobisisobutyl Nitrile was added in the stirred tank, and stirred for 30 minutes to obtain the mixed raw material after the solid particles were completely dissolved;

[0074] (c) The temperature of the mixed raw materials in the reaction kettle in step a is raised to 70°C, and after the reflux is stable, the mixed raw materials in step b are dropped into the reaction kettle,...

Embodiment 2

[0094] A low-temperature self-crosslinking waterborne acrylate resin: in parts by weight, consisting of the following raw materials:

[0095]

[0096] The preparation steps are as follows:

[0097] (a) Add 35g of propylene glycol methyl ether and 20g of ethylene glycol monobutyl ether into a reactor with a reflux condenser, stir and heat up to 70°C, and obtain a mixed solvent after the reflux is stable;

[0098] (b) Add 20g of vinyl acetate, 15g of methyl acrylate, 5g of isooctyl acrylate, 3g of methacrylic acid, 2g of hydroxypropyl acrylate and 0.8g of azobisisoheptanonitrile into the stirring tank, stir for 30 minutes until solid The mixed raw material is obtained after the particles are completely dissolved;

[0099] (c) Warm up the mixed raw materials in the reaction kettle in step a to 75°C, and after the reflux is stable, drop the mixed raw materials in step b into the reaction kettle, control the temperature at 75-80°C, and add the dropping time for 3 hours;

[010...

Embodiment 3

[0118] A low-temperature self-crosslinking water-based acrylate resin, in parts by weight, consists of the following raw materials:

[0119]

[0120]

[0121] The preparation steps are as follows:

[0122] (a) Add 25g of ethylene glycol monoethyl ether and 15g of propylene glycol methyl ether acetate into a reactor with a reflux condenser, stir and heat up to 80°C, and obtain a mixed solvent after the reflux is stable;

[0123] (b) 35g methyl acrylate, 15g butyl acrylate, 2g methacrylic acid, 1g itaconic acid, 1g hydroxyethyl acrylate, 1g hydroxypropyl methacrylate, 1.5g glycidyl methacrylate, 0.5g bis Add acetone acrylamide, 0.8g azobisisobutyronitrile and 0.4g benzoyl peroxide into the stirring tank, stir for 30 minutes until the solid particles are completely dissolved to obtain the mixed raw materials;

[0124] (c) Warm up the mixed raw materials in the reaction kettle in step a to 80°C, and after the reflux is stable, drop the mixed raw materials in step b into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com